When you specify paving materials for Arizona installations, paving stone color fading Arizona represents one of your most critical long-term performance concerns. You’re not just selecting aesthetic elements — you’re engineering solutions that must withstand some of North America’s most aggressive UV exposure conditions. Your material choices directly determine whether installations maintain their original appearance for decades or deteriorate into faded, inconsistent surfaces within five years.

Arizona’s unique combination of extreme solar radiation, minimal cloud cover, and extended daylight hours creates conditions that accelerate photodegradation in ways most standard specifications fail to address. You need to understand that UV intensity at Phoenix elevations reaches levels 40% higher than coastal regions, and when you factor in reflected radiation from surrounding hardscapes, effective UV exposure increases by another 15-20%. Your specification documents must account for these cumulative effects.

Material Composition and UV Resistance Fundamentals

The molecular structure of your selected paving material determines its inherent resistance to paving stone UV resistance Arizona conditions. You should understand that UV degradation occurs through photochemical reactions that break down color-bearing minerals and binding matrices. Natural stone materials with iron oxide pigmentation exhibit superior UV stability compared to synthetic colorants because crystalline iron compounds resist photodegradation.

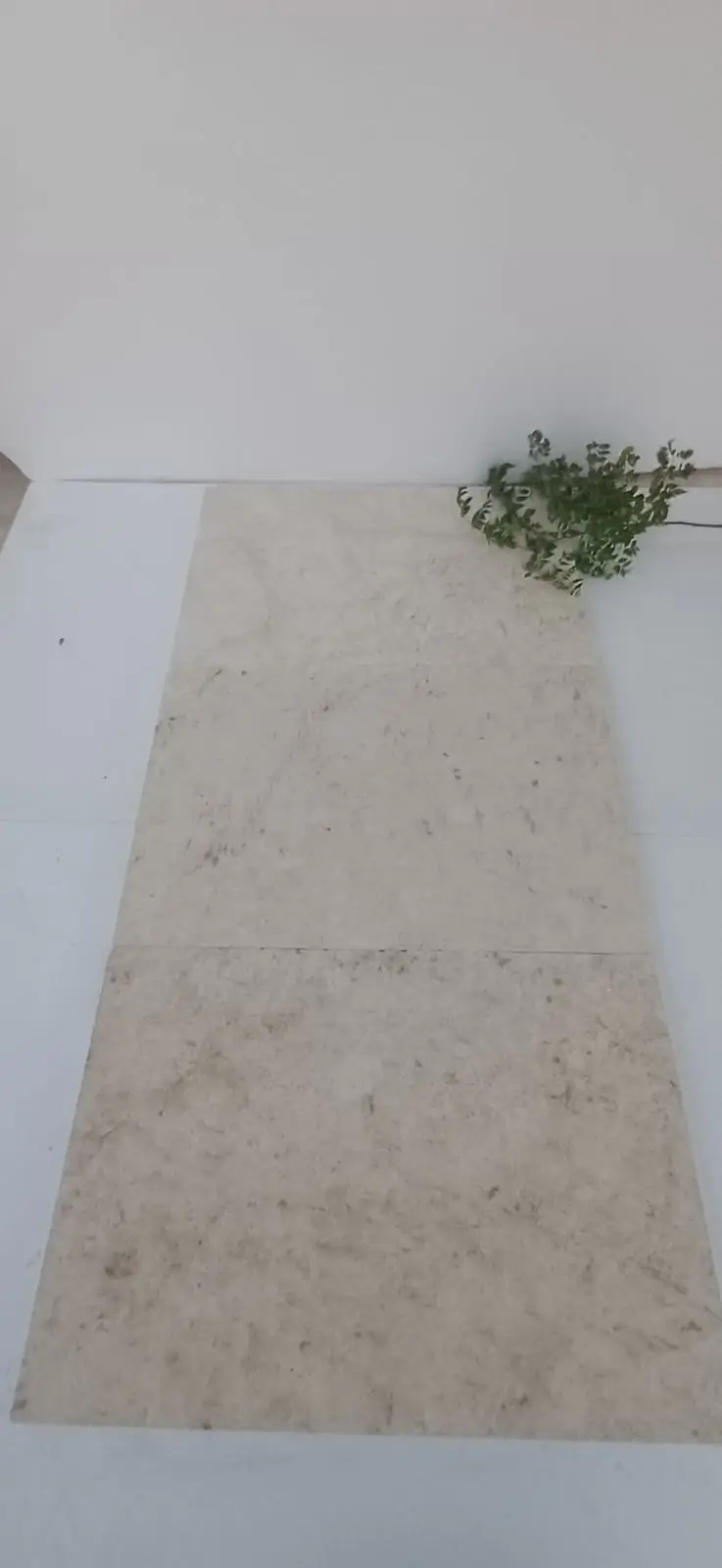

When you evaluate material options, calcium carbonate-based stones demonstrate different UV response characteristics than silicate-based materials. Limestone and travertine compositions naturally reflect 60-70% of incident solar radiation, reducing surface temperature by 25-30°F compared to darker materials. This thermal advantage translates directly to reduced UV stress on color-bearing minerals. Your specification should prioritize materials with proven photostability in desert environments.

You’ll find that porosity plays a dual role in color retention. Open-pore structures between 5-8% allow UV-protective sealers to penetrate deeply, creating subsurface protection layers. However, excessive porosity above 12% permits moisture intrusion that accelerates efflorescence and color leaching. Professional specifications balance these competing factors by selecting materials in the 6-7% porosity range for optimal sealer retention without moisture vulnerability.

Solar Radiation Impact Mechanisms Across Arizona Microclimates

Arizona’s elevation variations create dramatic differences in UV exposure that you must address in regional specifications. At Yuma’s 138-foot elevation, annual UV index averages reach 11.2, while Flagstaff at 7,000 feet experiences index values of 9.8 — but thinner atmosphere at elevation increases high-energy UV-B penetration by 8-10% per thousand feet. You can’t apply uniform specifications across the state and expect consistent performance.

Your installations face three distinct radiation sources: direct solar, diffuse atmospheric scatter, and ground reflection. In typical Arizona residential applications, ground reflection from concrete pool decks and stucco walls contributes 18-22% additional UV exposure beyond direct sunlight. When you design courtyard installations with reflective surfaces on multiple sides, cumulative UV exposure can exceed 140% of open-field values. This phenomenon explains why paving stone color fading Arizona occurs faster in enclosed hardscape areas than open landscapes.

- You need to calculate effective UV exposure by summing direct, diffuse, and reflected radiation components for accurate material selection

- Your site analysis should map reflective surfaces within 15 feet of paving installations to quantify cumulative UV loading

- You’ll achieve better performance by specifying UV-protective sealers with higher application rates in high-reflection environments

- Consider how seasonal sun angles affect reflection patterns — summer low-angle morning light creates maximum reflection conditions

Color Pigment Stability and Photodegradation Resistance

The specific mineral compounds that create color in your paving materials respond differently to UV exposure. Iron oxide pigments in red, brown, and tan ranges demonstrate exceptional photostability because their crystalline structure absorbs UV energy without molecular breakdown. You’ll see minimal color shift in materials with iron oxide concentrations above 4% by weight. Conversely, organic-based colorants and certain transition metal compounds degrade rapidly under Arizona UV conditions.

When you specify white or cream materials for paving stone sun damage Arizona projects, you’re working with calcium carbonate or dolomite compositions that naturally resist UV degradation. These materials don’t fade in the traditional sense — instead, they accumulate surface contamination that creates apparent color darkening. Your maintenance specifications should address this through periodic cleaning rather than sealer reapplication focused on UV protection.

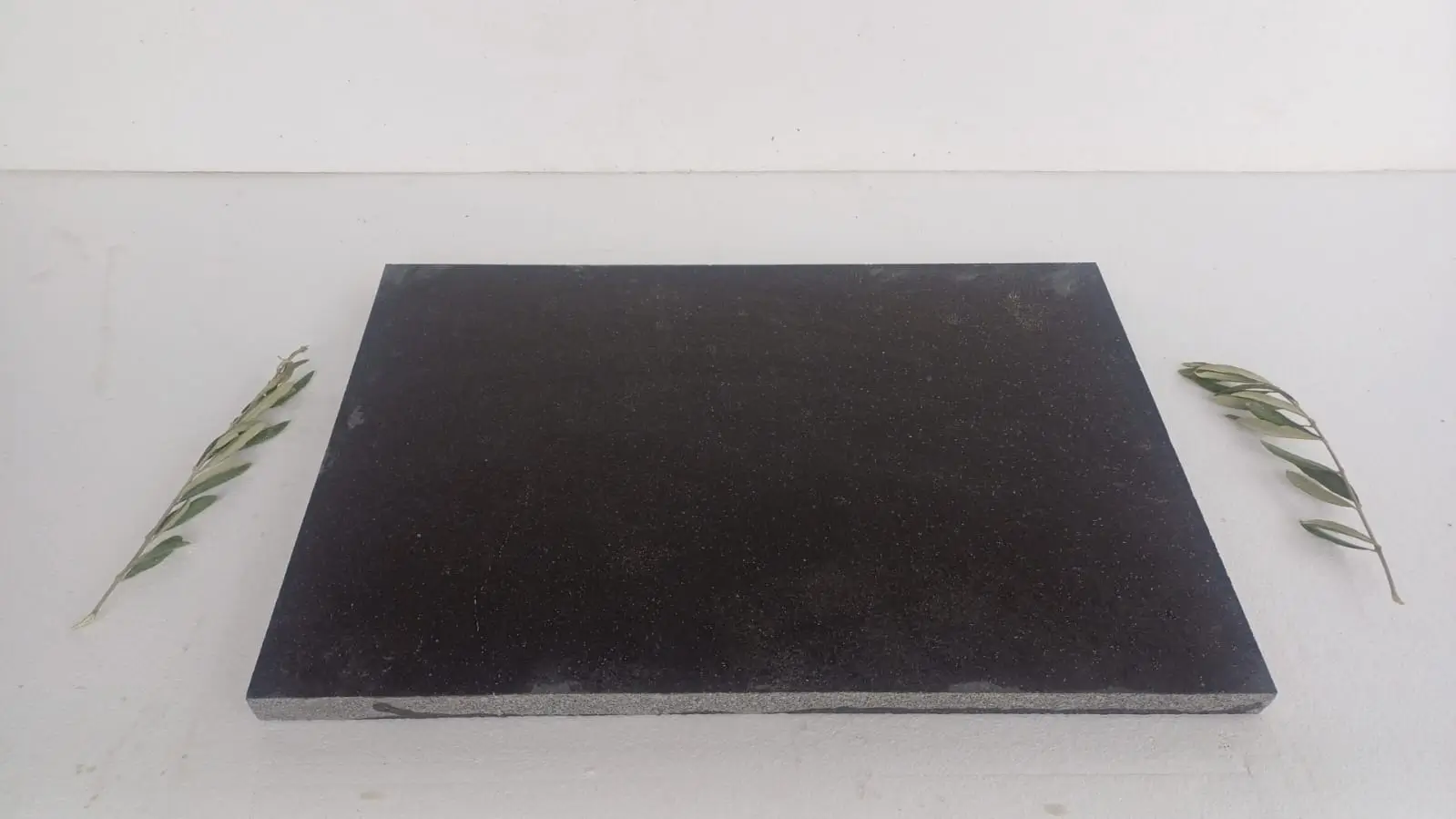

Darker materials present different challenges for paving stone bleaching prevention Arizona applications. Charcoal, black, and deep brown pavers derive color from manganese oxides, carbon inclusions, or dense mineral matrices. These compounds remain UV-stable, but surface oxidation creates lighter-toned layers that appear as fading. You need to distinguish between true pigment degradation and oxidation effects when you evaluate long-term performance data. Professional specifications for dark materials should include oxidation-resistant sealers with annual reapplication schedules.

Thermal Cycling and Its Role in Color Degradation

Surface temperatures on Arizona paving installations regularly reach 160-180°F during summer months, creating thermal stress that accelerates color fading through multiple mechanisms. You should understand that each heating-cooling cycle expands and contracts the stone matrix by 0.02-0.04%, generating microcracking that exposes fresh surfaces to UV attack. Over 200 annual thermal cycles, cumulative strain weakens color-bearing surface layers.

The relationship between thermal mass and color retention often surprises specifiers. Materials with higher density and specific heat capacity experience slower temperature rise and fall, reducing thermal cycling frequency. When you specify 2-inch thick pavers instead of 1.5-inch profiles, thermal cycling amplitude decreases by 15-18%, directly improving color retention. Your thickness specifications should account for thermal performance, not just structural requirements.

- You’ll reduce thermal stress by specifying lighter-colored materials that reflect 60%+ of solar radiation

- Your joint sand selection affects thermal performance — stabilized polymeric sand transfers heat differently than silica sand

- You need to account for substrate thermal properties when you calculate surface temperature ranges

- Consider specifying open-joint designs that allow convective cooling through gaps, reducing peak temperatures by 12-15°F

Sealer Technology for Maximum UV Protection

Modern penetrating sealers provide your primary defense against paving stone color fading Arizona through multiple protection mechanisms. Siloxane and silane-based formulations create hydrophobic barriers that prevent moisture intrusion while allowing vapor transmission. When you select sealers with UV-absorbing additives, surface-layer molecules intercept and dissipate UV energy before it reaches color-bearing minerals. Professional-grade formulations include benzotriazole or benzophenone compounds that absorb UV-A and UV-B wavelengths.

You need to understand that sealer performance degrades predictably under Arizona conditions. Initial application provides 85-90% UV protection, but annual exposure reduces effectiveness by 12-15% as UV absorbers become saturated and break down. Your maintenance specifications should require resealing every 18-24 months for optimal protection, not the 3-5 year intervals common in moderate climates. This accelerated schedule may seem excessive, but it prevents the cumulative damage that becomes irreversible.

Film-forming sealers create surface barriers that offer different trade-offs for paving stone color preservation Arizona projects. Acrylic formulations provide excellent initial UV protection and enhance color depth, but they require annual reapplication and create slip hazards when wet. Urethane-based products offer superior durability with 3-4 year service life, though higher initial cost and specialized application requirements limit their use. When you evaluate sealer options, balance UV protection against maintenance burden and slip resistance requirements.

Installation Techniques That Maximize Color Longevity

Your installation methodology directly affects long-term color retention through factors most specifications overlook. Base preparation quality determines how uniformly pavers settle, and differential settlement creates surface irregularities that trap moisture and debris. These pockets become focal points for accelerated color fading. You should specify 95% compaction for base layers with maximum 3% grade variance to ensure uniform drainage and prevent moisture accumulation.

Joint spacing affects color retention through thermal stress distribution. When you maintain consistent 3/16-inch joints, thermal expansion distributes evenly across the installation. Joints that vary beyond ±1/32 inch create stress concentrations that accelerate microcracking and surface degradation. Your installation specifications should require string-line joint alignment verification every 10 feet to maintain tolerance. This attention to detail prevents the premature surface breakdown that exposes fresh material to UV attack.

For guidance on comprehensive installation standards, see our paver stone distribution for regional best practices. You’ll find that proper initial installation prevents 60-70% of color fading issues that appear in years 5-10 of service life.

- You need to specify polymeric stabilizing sand for joints to prevent erosion that exposes paver edges to concentrated UV damage

- Your crew should apply initial sealer within 48 hours of installation completion, before surface contamination begins

- You must verify that base drainage directs water away from the installation to prevent subsurface moisture that accelerates efflorescence

- Consider specifying edge restraints that accommodate thermal expansion without transferring stress to paver surfaces

Maintenance Protocols for Long-Term Color Preservation

Even properly specified installations require proactive maintenance to combat paving stone sun damage Arizona conditions. You should establish cleaning schedules that remove accumulated organic matter, mineral deposits, and atmospheric pollutants before they bond permanently to surfaces. Quarterly pressure washing at 1,200-1,500 PSI with 25-degree nozzles removes surface contamination without damaging sealer layers or opening pores to deeper penetration.

Your maintenance specifications need to address the alkaline dust accumulation unique to Arizona environments. Desert soils with pH values of 8.0-8.5 generate airborne particles that settle on paving surfaces and react with moisture to create whitish films. These deposits aren’t efflorescence in the traditional sense, but they create similar appearance issues. You’ll achieve better results by specifying pH-neutral cleaners applied monthly during dust season rather than aggressive acid treatments that damage sealers.

Resealing schedules must account for actual UV exposure rather than calendar intervals. Installations with southern exposure and minimal shade require sealer renewal every 18 months, while north-facing or partially shaded areas perform adequately with 30-month intervals. You should conduct annual water-drop absorption tests to verify sealer effectiveness — if water penetrates within 30 seconds, resealing is overdue. This performance-based approach optimizes maintenance costs while preventing the UV damage that occurs when sealer protection lapses.

Material Selection Strategies for Arizona’s Extreme UV Environment

When you specify materials specifically for paving stone UV resistance Arizona applications, natural stone options provide inherent advantages over manufactured alternatives. Limestone and travertine quarried from deep formations develop their coloration through geological processes that create UV-stable mineral structures. You’re working with pigments that have remained stable for millions of years — they won’t suddenly degrade under a few decades of sunlight exposure.

Color selection dramatically impacts long-term appearance retention. Lighter tones in the cream, beige, and light gray ranges maintain consistent appearance because subtle fading remains imperceptible. When you specify white materials, you eliminate color-shift concerns entirely. Mid-tone browns and tans provide the best balance of aesthetic warmth and fade resistance, as their iron oxide pigmentation resists photodegradation while masking minor surface changes that occur over time.

- You should avoid materials with artificially enhanced colors or surface treatments that may degrade faster than the base stone

- Your specifications must verify that colorant minerals are distributed throughout the material depth, not just surface-applied

- You’ll achieve better performance with materials that show consistent color in both wet and dry states, indicating stable mineral pigmentation

- Consider specifying materials from quarries with documented Arizona installations showing 15+ year color stability

Surface Finish Impact on UV Degradation Rates

The surface texture you specify affects paving stone bleaching prevention Arizona through exposure geometry and thermal properties. Honed finishes with smooth surfaces present minimal texture that could trap contaminants, but they also maximize direct UV exposure to color-bearing minerals. Tumbled or antiqued finishes create irregular surfaces that diffuse UV radiation across varying angles, reducing effective exposure by 8-12%. However, these textured surfaces accumulate more organic debris that requires intensive cleaning.

You need to understand that surface porosity varies with finishing method. Thermal finishing partially closes surface pores through localized melting, creating a denser surface layer that resists both UV penetration and moisture absorption. When you specify thermally finished materials for high-UV areas, you’re adding an additional protective layer without separate sealer application. This approach works particularly well for commercial applications where maintenance budgets limit regular resealing.

Sandblasted finishes open surface pores and increase effective surface area by 20-30%, creating more opportunities for UV attack on color-bearing minerals. You should avoid specifying sandblasted finishes for Arizona installations unless aesthetic requirements demand the texture. If you must use textured finishes, compensate by specifying premium penetrating sealers with enhanced UV absorbers and shortening resealing intervals to 12-15 months.

Environmental Factor Interactions Beyond Direct UV Exposure

Paving stone color fading Arizona results from complex interactions between UV radiation and other environmental stressors. You must account for how dust storms deposit abrasive particles that physically erode surface layers, exposing fresh material to UV attack. Each monsoon season brings 3-5 major dust events that sandblast exposed surfaces with silica particles. This mechanical wear removes 0.002-0.004 inches of material annually — seemingly minor, but it continuously exposes unweathered stone to UV degradation.

Alkaline groundwater in many Arizona regions creates subsurface conditions that accelerate surface breakdown. When you install pavers over soils with pH above 8.0, capillary action draws alkaline moisture upward during temperature drops. This moisture emerges at the surface, depositing mineral salts that disrupt color-bearing compounds. Your specifications should include vapor barriers over alkaline soils and specify drainage systems that prevent capillary rise.

- You need to account for monsoon moisture cycles that create rapid wet-dry transitions accelerating surface breakdown

- Your site analysis should test soil pH and specify appropriate moisture barriers where alkalinity exceeds 7.5

- You’ll prevent compounding damage by specifying proper drainage that eliminates standing water within 4 hours of rainfall

- Consider how nearby vegetation affects microclimate humidity and shade patterns that moderate UV exposure

Citadel Stone’s Premium Paving Stones Front Yard in Arizona: Regional Performance Specifications

When you evaluate Citadel Stone’s paving stones front yard in Arizona solutions for your projects, you’re specifying materials engineered specifically for extreme UV environments. At Citadel Stone, we provide technical consultation for hypothetical installations across Arizona’s diverse climate zones. This section demonstrates how you would approach material selection and specification requirements for six representative cities, accounting for their unique environmental conditions.

Professional specifications for Arizona applications require you to balance UV resistance with thermal performance, moisture management, and long-term maintenance requirements. The following city-specific guidance illustrates how regional factors affect your specification decisions for paving stone color preservation Arizona projects.

Phoenix Valley Applications

In Phoenix installations, you would need to address UV index values averaging 11.8 during peak season combined with ambient temperatures exceeding 115°F for extended periods. Your specifications should prioritize light-colored materials with solar reflectance above 65% to manage surface temperatures. You’d specify premium UV-resistant sealers with mandatory 18-month reapplication schedules to combat the 340+ annual days of direct sunlight. When you consider Phoenix’s urban heat island effects, substrate temperatures beneath installations reach 140-150°F, requiring you to account for enhanced thermal cycling in joint spacing calculations. You would increase expansion joint frequency to every 12 feet rather than standard 15-foot spacing.

Tucson Desert Conditions

For Tucson projects, you’d address similar UV intensity to Phoenix but with 15% higher annual dust exposure from surrounding desert terrain. Your maintenance specifications would require monthly cleaning during April-September dust season to prevent alkaline particle accumulation that accelerates paving stone color fading Arizona. You should specify materials with Mohs hardness above 4.0 to resist abrasive dust erosion that removes protective sealer layers. When you plan Tucson installations, you’d account for monsoon season moisture that creates rapid wet-dry cycling — this requires you to specify sealers with enhanced water repellency to prevent moisture-driven efflorescence during July-August precipitation events.

Scottsdale Residential Standards

Scottsdale’s luxury residential market would require you to emphasize aesthetic longevity alongside functional performance. You’d specify premium materials with demonstrated 20+ year color stability and recommend protective sealer systems that enhance color depth while providing UV protection. Your specifications should address how pool deck adjacency increases reflected UV exposure by 25-30%, requiring you to upgrade from standard to premium sealer formulations. When you design Scottsdale installations, you’d typically work with architect-specified color palettes that demand precise long-term color matching — this requires you to verify warehouse stock depths ensure consistent material sourcing throughout project phases and future repair needs.

Flagstaff Elevation Considerations

At Flagstaff’s 7,000-foot elevation, you would address different UV challenges than low-desert locations. Thinner atmosphere increases high-energy UV-B penetration by 15-18% compared to Phoenix, but cooler temperatures reduce thermal cycling stress. Your specifications should emphasize UV-B-specific sealer protection while addressing freeze-thaw durability requirements uncommon in lower elevations. You’d need to specify materials with water absorption below 3% and verified freeze-thaw resistance exceeding 100 cycles. When you plan Flagstaff installations, you would account for 90-100 annual freeze-thaw events that compound UV damage through surface microcracking, requiring you to specify enhanced sealer penetration depths.

Sedona Aesthetic Integration

Sedona projects would require you to specify earth-tone materials that complement surrounding red rock formations while resisting UV degradation. You’d work with iron-oxide-rich materials in terracotta, rust, and amber ranges that provide inherent UV stability through their mineral composition. Your color selection should account for how intense UV exposure gradually lightens even stable pigments by 5-8% over 15-20 years. When you specify for Sedona’s tourism-focused commercial applications, you would recommend maintenance schedules aligned with high foot traffic and tourist season demands. You’d need to coordinate warehouse delivery timing with seasonal access constraints on narrow canyon roads that limit truck access during peak visitor periods.

Yuma Extreme UV Environment

Yuma represents Arizona’s most challenging UV environment, where you would address the nation’s highest annual sunshine hours at 4,015 hours — 91% of possible daylight. Your specifications must include the most aggressive UV protection measures: premium sealers with maximum UV absorber concentrations and 12-15 month reapplication intervals. You should specify materials proven in similar extreme-exposure environments with documented performance data. When you calculate lifecycle costs for Yuma installations, accelerated sealer renewal requirements increase annual maintenance costs by 35-40% compared to moderate climates — your budget presentations should reflect these realistic long-term expenses to prevent client disappointment when maintenance needs emerge.

Specification Language for UV Protection Requirements

Your construction documents need precise language that contractors can execute and that establishes measurable performance criteria. Generic statements like “provide UV-resistant materials” lack enforceability. Instead, you should specify: “Provide natural stone paving materials with demonstrated color stability showing less than 5% color shift (measured by spectrophotometry) after 5,000 hours accelerated UV exposure per ASTM G154 Cycle 4.” This language creates testable requirements.

When you write sealer specifications, define both product requirements and application protocols. Professional specifications state: “Apply penetrating siloxane sealer with benzotriazole UV absorbers at manufacturer’s recommended coverage rate plus 15%. Verify absorption by water-drop test showing 60+ second repellency before final acceptance. Provide contractor warranty for sealer reapplication at 18-month intervals for initial 5 years.” This comprehensive approach establishes quality standards and long-term maintenance responsibilities.

- You need to specify material testing requirements including accelerated UV exposure documentation from independent laboratories

- Your warranty language should address color stability with measurable criteria rather than subjective appearance judgments

- You must define maintenance requirements as specification provisions, not separate maintenance manuals that get ignored

- Consider specifying material substitution procedures that require equivalent UV testing documentation for any proposed alternatives

Lifecycle Cost Analysis for UV-Resistant Installations

When you present material recommendations to clients, lifecycle cost analysis demonstrates the value of UV-resistant specifications. Initial material cost premiums of 15-25% for superior UV-stable materials become negligible when you calculate 30-year ownership costs. You should develop cost models that include material, installation, sealer application (every 18 months), cleaning (quarterly), and eventual replacement. These calculations consistently show that premium UV-resistant materials with proper maintenance cost 30-40% less over three decades than economy materials requiring replacement at year 15.

Your cost analysis needs to account for replacement complexity that exceeds new installation costs. When existing installations fail due to color fading, you’re not just replacing material — you’re removing degraded pavers, verifying base integrity, matching discontinued colors, and coordinating occupied-space construction. These factors typically increase replacement costs to 160-180% of equivalent new installation. When you present these realities to clients, specification upgrades for UV protection become obvious value propositions.

Future Performance Considerations

As you develop specifications for current projects, you should anticipate how climate trends affect long-term performance. Arizona temperature records show consistent warming of 0.3-0.4°F per decade, with corresponding increases in UV intensity as atmospheric moisture decreases. Your 30-year performance projections should assume 5-7% higher cumulative UV exposure than current conditions indicate. This forward-looking approach prevents premature obsolescence of today’s installations.

Material technology continues evolving, with nano-particle sealer additives and surface-modified stones entering the market. You need to evaluate these innovations critically, distinguishing between proven performance improvements and marketing claims. When manufacturers present new UV-protective technologies, you should require independent testing documentation showing minimum 2,000-hour accelerated exposure with less than 3% color shift. Your specifications can reference emerging technologies while maintaining performance-based requirements that ensure quality regardless of specific products.

Your professional responsibility extends beyond initial installation to long-term client satisfaction. Paving stone color fading Arizona remains a persistent challenge, but proper material selection, installation protocols, and maintenance specifications achieve excellent 20-30 year performance. You should educate clients about realistic expectations, maintenance commitments, and lifecycle value propositions. For additional technical guidance on restoration when UV damage does occur, review Professional techniques for repairing and restoring damaged paving stones before you finalize your long-term maintenance recommendations. Citadel Stone’s trade pricing makes it competitive wholesale paver stones in Arizona supplier.