When you design outdoor entertainment spaces in Arizona’s extreme climate, integrating lighting with patio stone installations requires you to balance thermal performance, electrical infrastructure, and long-term material durability. Your patio stone lighting integration Arizona project demands more than surface-level aesthetic planning — you need to understand how heat retention, coefficient of thermal expansion, and subsurface conduit placement interact with stone selection and base preparation. Most specification failures occur when you treat lighting as an afterthought rather than engineering it into the foundational design from the start.

Arizona’s temperature extremes create unique challenges you won’t encounter in temperate climates. Surface temperatures on dark-colored stone can exceed 160°F during peak summer months, which affects transformer performance, LED lifespan, and wire insulation integrity. You’ll need to account for these thermal loads when you specify burial depths, fixture materials, and control system locations. The decisions you make during the design phase determine whether your installation performs reliably for 20+ years or requires costly remediation within the first 36 months.

Thermal Considerations for Lighting Infrastructure

Your patio stone lighting integration Arizona specification must address substrate temperature cycling that ranges from winter lows near freezing to summer highs approaching 170°F at the stone-to-base interface. This 140+ degree annual range creates expansion and contraction cycles that standard residential electrical codes don’t adequately address. When you embed conduit and junction boxes within aggregate base layers, you’re creating potential failure points unless you account for differential thermal movement between metallic components and surrounding materials.

Conduit burial depths require adjustment from standard practice in Arizona installations. You should maintain minimum 6-inch coverage below finished stone surface for PVC Schedule 40 conduit, increasing to 8 inches in areas with vehicular traffic potential. Metallic conduit demands even greater attention — thermal expansion coefficients for rigid steel conduit (6.5 × 10⁻⁶ per °F) differ substantially from surrounding crushed aggregate, creating stress concentration points at junction box connections. Your patio stone illumination design Arizona approach needs expansion loops every 75-90 feet in straight runs exceeding that length, positioned within accessible junction boxes rather than buried inaccessibly beneath finished pavement.

- You need to specify burial depths that account for thermal cycling and mechanical load transfer

- Your conduit routing should avoid crossing expansion joints in the finished stone surface

- You must coordinate electrical rough-in with base compaction operations to prevent settlement-induced conduit damage

- Junction box locations require mapping and documentation for future service access

- Transformer placement should occur in ventilated areas with ambient temperatures below 95°F

Fixture Selection and Thermal Performance

LED fixtures rated for ambient operation to 122°F fail prematurely in Arizona patio installations where substrate temperatures routinely exceed that threshold. You’ll encounter this specification error repeatedly in manufacturer literature that assumes temperate climate conditions. When you install patio stone accent lighting Arizona fixtures in direct contact with stone surfaces that reach 160°F, you’re operating electronics 30-40 degrees beyond their design envelope. The result appears 18-24 months post-installation as color shift, reduced output, and premature driver failure.

High-temperature LED modules rated for 140°F ambient operation provide the minimum acceptable specification for Arizona applications. You should verify that fixture housings incorporate thermal management features — finned aluminum heat sinks, convective ventilation paths, and thermally conductive mounting interfaces that facilitate heat transfer away from LED junctions. Your patio stone outdoor lighting Arizona fixture selection must account for substrate thermal mass, which delays peak fixture temperature by 3-4 hours after peak solar gain. This means maximum fixture stress occurs at 7-9 PM during summer months when systems operate at full output while substrate heat dissipates.

- Specify fixtures with minimum 140°F ambient temperature ratings for substrate-mounted applications

- Verify LED modules use high-temperature phosphor compounds rated above 150°C junction temperature

- Select drivers with Class 2 thermal protection and automatic dimming at elevated temperatures

- Avoid plastic fixture housings in favor of cast aluminum or marine-grade bronze

- Require IP67 or higher ingress protection for uplighting installations in stone recesses

Uplighting Installation Methodology

Recessed uplighting requires you to coordinate fixture rough-in with stone layout in ways that standard lighting design doesn’t address. When you create recesses for flush-mounted uplights within patio stone fields, you’re introducing thermal discontinuities and potential water infiltration paths that compromise base stability if improperly detailed. The fixture recess becomes a thermal chimney during cooling cycles, drawing moisture into the aggregate base through condensation and capillary action unless you install vapor barriers and drainage provisions.

Your installation methodology should incorporate individual fixture sleeves — 6-inch diameter PVC pipe sections extending from 2 inches below finished stone surface down to undisturbed subgrade. This creates a defined boundary that isolates the fixture from surrounding base materials and provides positive drainage away from electrical components. You’ll backfill the annular space between fixture housing and sleeve with open-graded pea gravel that facilitates water drainage while maintaining thermal isolation. The stone unit directly above requires through-boring with diamond core bits sized 1/8 inch larger than fixture trim diameter, allowing thermal expansion without creating pressure points that crack the stone.

Fixture placement relative to stone joints determines long-term performance. You need to position uplights minimum 4 inches from any stone edge to prevent thermal stress concentration and joint sand migration into fixture housings. When you plan patio stone LED installation Arizona uplight locations, you should create scaled layout drawings that show exact fixture coordinates relative to stone module dimensions before you begin base preparation. This prevents field modifications that compromise installation quality and lead to misaligned fixtures that don’t align with architectural features you’re illuminating.

Pathway Lighting Integration Approaches

Pathway lighting along patio stone edges requires different infrastructure than uplighting within the field. You’ll typically install pathway fixtures in adjacent landscape beds or turf areas where you can trench conduit without disturbing finished paving. This separation simplifies installation but creates aiming challenges — pathway lights positioned 12-18 inches from patio edges must project illumination across the vertical grade change between landscape bed and finished paving surface without creating glare for people seated at patio level.

Fixture height specifications determine whether your pathway lighting enhances or degrades the space. You should specify pathway lights with maximum 18-inch above-grade mounting heights and asymmetric distribution patterns that direct 70% of lumens toward the paving surface while limiting upward light to 15% of total output. Arizona’s clear night skies make dark sky compliance particularly important — you need fixtures that shield lamp sources from direct view at angles above 80 degrees from vertical. Your patio stone illumination design Arizona should incorporate glare control as a performance specification, not an aesthetic preference.

- Position pathway fixtures 12-18 inches from patio edge in landscape beds for serviceability

- Specify asymmetric distributions that maximize horizontal illumination while minimizing vertical spill

- Verify fixture mounting heights don’t exceed 18 inches above adjacent finished grade

- Select dark sky compliant fixtures with zero upward light component above 80-degree angle

- Coordinate fixture spacing with typical walking pace to create even illumination without hot spots

LED System Specifications and Color Rendering

Color temperature selection affects how stone appearance changes from daylight to nighttime conditions. When you specify patio stone accent lighting Arizona systems, you’re choosing whether to maintain natural stone color or create dramatic shifts in perceived hue. Warm white LEDs at 2700K-3000K preserve the appearance of buff, tan, and terracotta stone tones while making gray and blue-gray stones appear warmer than daylight conditions. Cool white LEDs at 4000K-5000K maintain gray stone appearance but make warm-toned materials look washed out and less vibrant.

Color rendering index (CRI) matters more in architectural lighting than pathway illumination. You should specify minimum CRI 90 for accent lighting that highlights specific stone features, textural details, or material transitions. Standard CRI 80 LEDs suffice for pathway applications where you’re providing navigation lighting rather than showcasing material character. The cost differential between CRI 80 and CRI 90 modules runs approximately 30-40%, which you need to justify based on project goals and budget constraints.

Your patio stone outdoor lighting Arizona specification should address lumen maintenance and long-term color stability. Quality LED modules maintain 90% of initial output at 50,000 hours (L90/50K rating) while budget products drop to 70% output at the same interval (L70/50K). This performance difference becomes visible within 4-5 years of continuous operation as budget fixtures dim noticeably while premium products maintain consistent output. You’ll also encounter color shift issues with budget LEDs — the phosphor compounds degrade unevenly, causing warm white fixtures to shift toward yellow-green hues that distort stone appearance.

Control Systems and Automation Integration

Lighting control architecture ranges from simple photocell activation to networked systems with astronomical timeclocks, occupancy sensing, and smartphone integration. Your selection depends on project complexity, budget allocation, and owner maintenance capabilities. Single-family residential installations typically function well with photocell control and manual override switching. Commercial hospitality and multifamily projects benefit from astronomical timeclocks that adjust on/off times based on sunrise/sunset calculations, eliminating the drift that occurs with photocell-only systems as seasonal daylight patterns change.

Low-voltage DC systems (12V, 24V) dominate patio stone LED installation Arizona applications because they offer installation flexibility, reduced shock hazard, and compatibility with solar charging in remote locations without utility power access. You need to calculate voltage drop carefully — runs exceeding 75 feet require wire gauge increases from typical 12 AWG to 10 AWG or 8 AWG to maintain voltage within ±10% of nominal at fixture locations. Voltage drop causes LED dimming and color shift, with fixtures farthest from the transformer running noticeably dimmer than those near the power source.

- Calculate voltage drop for worst-case circuit runs and upsize wire gauge to maintain ±10% voltage tolerance

- Position transformers centrally to minimize maximum circuit run length

- Specify transformers with 120% capacity margin above calculated connected load

- Install transformers in ventilated locations with ambient temperatures below 95°F

- Verify control systems provide independent zone switching for pathway versus accent lighting

Base Preparation and Electrical Coordination

Conduit installation timing relative to base preparation determines whether you achieve proper compaction around electrical infrastructure. When you install conduit after base compaction, you’re creating trenches that disrupt the load-bearing capacity you just established. The correct sequence requires you to rough-in conduit and junction boxes on prepared subgrade, then build aggregate base layers around the electrical infrastructure with hand compaction in 2-inch lifts within 12 inches of conduit runs. This maintains base integrity while protecting buried components from compaction equipment damage.

You should avoid crossing patio stone expansion joints with conduit runs. Expansion joints accommodate thermal movement and settlement — when you bridge these joints with rigid conduit, you’re creating stress concentration points that eventually crack the conduit or pull apart threaded connections. Your electrical layout needs to route conduit parallel to expansion joints, crossing only where absolutely necessary using flexible liquidtight conduit sections that accommodate movement. For more detailed guidance on base preparation and drainage integration, see our courtyard paving facility for comprehensive specification resources.

Junction box placement requires coordination with finished stone layout. You need to position boxes where you can access them through removable stone units rather than burying them permanently beneath fixed pavers. This requires scaled layout drawings that show junction box locations relative to stone module dimensions, ensuring boxes align with joint lines rather than landing in the center of stone units. You’ll mark junction box locations with permanent subsurface markers — tracer wire or detectable warning tape — that allow you to locate boxes years later when troubleshooting or expanding the system.

Water Management and Electrical Safety

Arizona’s monsoon season delivers intense rainfall that tests waterproofing details around electrical components. When you install junction boxes and transformers in grade-level applications, you’re creating potential water collection points that compromise electrical safety if improperly sealed. Junction boxes require gasket seals on covers with IP65 minimum rating, and you should install them with cover plates sloped to shed water rather than allowing horizontal surfaces that pond moisture.

GFCI protection presents challenges in low-voltage landscape lighting systems. The transformer primary side (120V) requires GFCI protection per NEC requirements, but nuisance tripping occurs frequently when moisture infiltrates the secondary (12V/24V) circuit wiring. You’ll minimize nuisance trips by specifying direct-burial rated cable rather than running individual THWN conductors through conduit, maintaining minimum 6-inch burial depth, and avoiding sharp bends that damage insulation. When GFCI tripping persists, you may need to isolate problematic circuit zones and investigate for damaged wire insulation or fixture seal failures.

- Specify junction boxes with IP65 minimum rating and gasketed covers

- Install junction box covers with slight slope to shed water accumulation

- Use direct-burial cable rather than individual conductors in conduit to reduce moisture infiltration

- Provide GFCI protection on transformer primary circuits per NEC requirements

- Install transformers minimum 12 inches above grade in ventilated weather-resistant enclosures

Material Compatibility Considerations

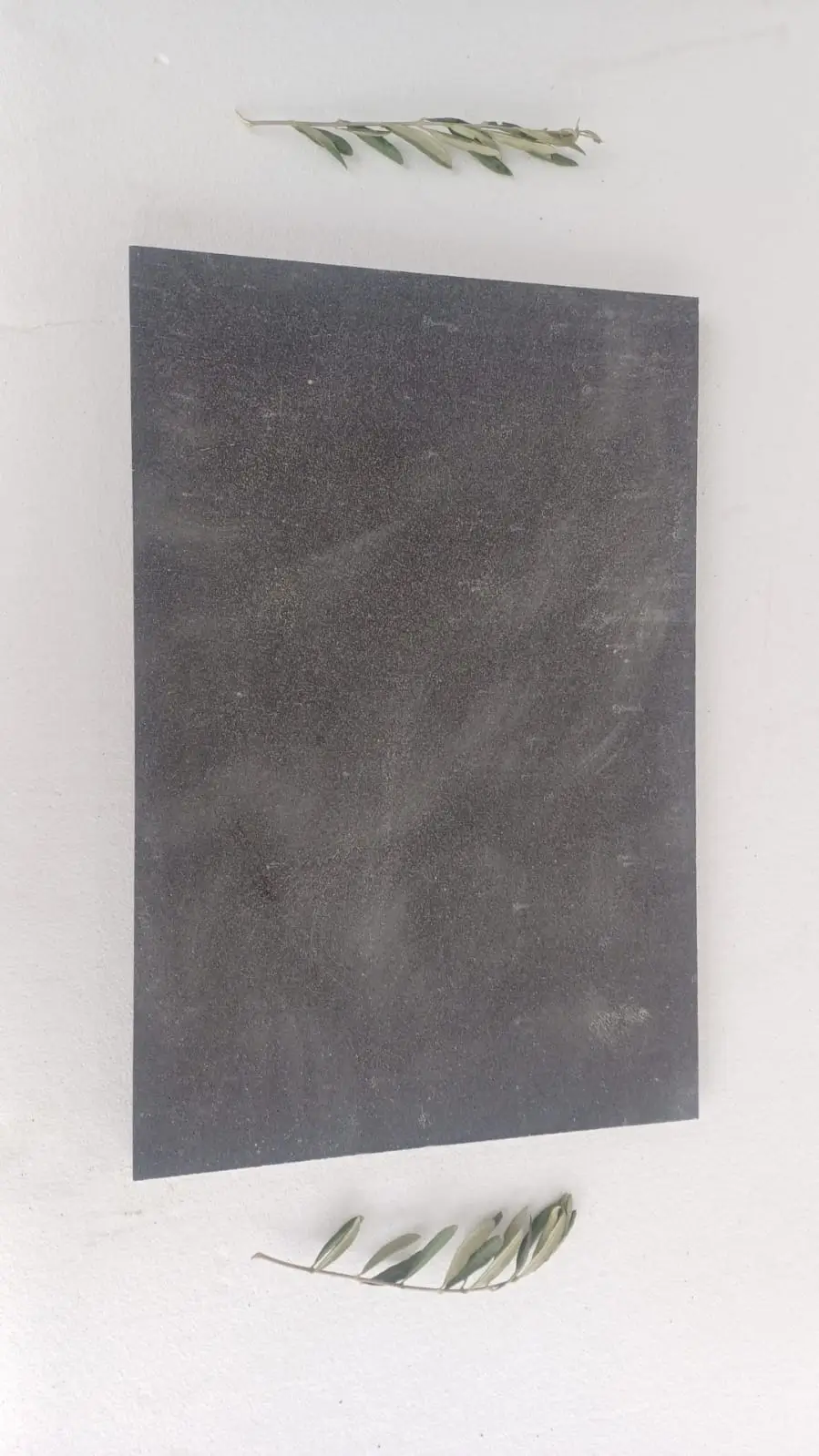

Stone thermal properties affect fixture performance and installation methodology. Dense, low-porosity materials like granite and basalt retain heat longer than porous limestone and sandstone, creating elevated nighttime substrate temperatures that stress LED components. When you specify patio stone lighting integration Arizona systems for dark granite or basalt installations, you need higher-rated LED modules and more aggressive heat-sinking than equivalent systems in buff limestone.

Stone color influences heat retention through albedo effect — light-colored materials reflect 50-60% of incident solar radiation while dark materials absorb 70-80%. This creates substrate temperature differentials of 30-40°F between light and dark stone selections under identical solar exposure. Your fixture specifications should account for these thermal differences by derating LED output 10-15% for dark stone applications or specifying higher-temperature-rated components that maintain performance in elevated thermal environments.

Porous stones like sandstone and some limestones present moisture challenges that affect buried electrical components. These materials can transmit water through capillary action, creating locally elevated moisture conditions in the aggregate base layer directly beneath the stone surface. You’ll need to incorporate geotextile barriers between stone and base in high-porosity applications, preventing moisture migration that could compromise wire insulation or junction box seals over extended service life.

Citadel Stone – Best Paver Stones Bulk in Arizona for Professional Lighting Integration

When you evaluate Citadel Stone’s paver stones bulk in Arizona for your lighting integration project, you’re considering materials engineered for extreme thermal cycling and UV exposure that characterizes the Southwest climate. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low-desert heat islands to high-elevation freeze-thaw environments. This section outlines how you would approach material and lighting specification decisions for six representative cities, accounting for regional variations in temperature extremes, monsoon intensity, and installation conditions.

Phoenix Heat Island Performance

In Phoenix’s extreme urban heat island, you would specify light-colored stone with high solar reflectance to minimize surface temperatures that stress LED components. Your installation would require substrate-mounted fixtures rated for 150°F ambient operation, with thermal barriers between fixture housings and stone surfaces. You’d position transformers in shaded alcoves with ventilation rather than exposing them to direct solar gain. Typical Phoenix installations would incorporate timer overrides that delay system activation until substrate temperatures drop below 130°F, approximately 90 minutes after sunset during peak summer months. Your base preparation would include additional compaction passes to counteract thermal expansion in expansive clay soils common throughout the Valley.

Tucson Monsoon Considerations

Tucson’s intense monsoon activity would drive you to specify enhanced drainage provisions around electrical components. Your design would route conduit with continuous grade toward collection points, avoiding horizontal runs that trap water during heavy rainfall events. Junction boxes would require installation 3-4 inches above nominal subgrade with gravel sumps below to prevent submersion during extreme precipitation. You’d specify marine-grade fixture housings with IP68 rating rather than standard IP65, accounting for occasional temporary submersion during monsoon flooding. Desert-adapted landscape integration would position pathway lighting in rock mulch beds rather than irrigated turf, eliminating moisture exposure from sprinkler overspray that degrades wire insulation.

Scottsdale Luxury Integration Standards

Your Scottsdale specification would emphasize premium fixtures with architectural-grade finishes that complement high-end stone installations. You’d specify CRI 95+ LED modules in warm white (2700K) to enhance natural stone coloration in entertainment spaces where material aesthetics drive design decisions. Control systems would incorporate smartphone integration and zone-specific dimming rather than simple on/off switching. Fixture placement would follow formal geometric patterns coordinated with stone module layout, requiring precise survey control and CAD coordination. You’d coordinate lighting rough-in with outdoor kitchen and water feature electrical systems, consolidating transformer locations and creating accessible maintenance zones that don’t compromise landscape design intent.

Flagstaff Freeze-Thaw Environment

Flagstaff’s freeze-thaw cycling would require you to specify cold-weather-rated components that maintain performance below 0°F. Your fixture selection would emphasize sealed housings that prevent moisture infiltration and subsequent freeze damage to internal components. Conduit burial would increase to 12-inch minimum depth to position electrical infrastructure below frost line depth. You’d avoid uplighting installations entirely in favor of pathway and bollard fixtures that elevate components above snow accumulation and freeze-thaw affected substrate layers. LED drivers would require cold-start capability that maintains full output at -20°F ambient conditions. Your stone selection would emphasize freeze-thaw resistant materials with absorption rates below 3% to prevent spalling that could damage adjacent lighting fixtures.

Sedona Dark Sky Compliance

Sedona’s dark sky ordinances would drive your fixture selection toward fully shielded designs with zero upward light component. You’d specify pathway lights with house-side shields that direct illumination only toward patio surfaces, eliminating light trespass toward natural desert areas. Fixture mounting heights would not exceed 15 inches above grade, and you’d incorporate amber LED modules (1800K-2200K) that minimize blue light spectrum emissions affecting nocturnal wildlife. Your control strategy would include automatic dimming to 30% output after 10 PM, reducing energy consumption and light pollution during late-night hours. Installation methodology would minimize disturbance to native vegetation and natural drainage patterns, positioning conduit runs within developed patio areas rather than trenching through pristine desert landscape.

Yuma Extreme Temperature Specification

Your Yuma specification would address the most extreme sustained heat in the continental United States, with summer temperatures exceeding 110°F for extended periods. You’d specify industrial-grade LED modules rated for 160°F continuous operation, recognizing that substrate temperatures will exceed air temperature by 40-50°F during peak summer months. Conduit and wire would receive increased burial depth (8 inches minimum) to reduce thermal exposure from superheated surface layers. Transformer placement would occur inside climate-controlled spaces with outdoor-rated disconnect switches rather than exposing electronic components to 115°F+ ambient conditions. Your design would incorporate manual override switching that allows homeowners to disable the system during extreme heat events when fixture operation risks premature component failure. Stone selection would favor light-colored materials with maximum solar reflectance to minimize heat retention that stresses electrical infrastructure.

Installation Sequencing and Coordination

Proper installation sequencing prevents damage to electrical components and ensures base integrity. You should complete all conduit rough-in and junction box installation before you begin aggregate base placement. This allows you to verify electrical system continuity and identify any damaged conduit before you cover the infrastructure with compacted base materials. Once you’ve confirmed electrical system integrity, you’ll build base layers around the electrical components using hand compaction within 12 inches of conduit and machine compaction beyond that radius.

Stone installation occurs after electrical rough-in and base preparation are complete, but before you install fixtures in recessed uplighting applications. You’ll core-drill fixture openings through installed stone units, which allows you to adjust hole locations slightly if stone module layout varies from design drawings. This prevents the frustration of pre-drilling fixture holes only to discover they don’t align with final stone positions after field adjustments for dimensional tolerance. You should install fixtures as the final step, after stone setting and joint sand placement are complete, minimizing exposure to construction traffic that could damage trim rings or lens components.

Maintenance Access Provisions

Long-term system serviceability requires you to plan maintenance access during the design phase. Junction boxes need to be accessible through removable stone units rather than buried beneath fixed pavers or large-format slabs. Your installation drawings should identify which specific stone units provide access to electrical components, and you should mark those units on the underside with permanent marker indicating junction box locations below. This prevents future service technicians from removing wrong stones when troubleshooting system failures.

Transformer locations should provide tool access for wire terminal servicing and component replacement without requiring landscape demolition. You’ll typically position transformers in planting beds, behind low walls, or within equipment alcoves that offer access while concealing equipment from primary viewing areas. Transformer mounting should elevate components minimum 12 inches above grade to prevent submersion during heavy rainfall and facilitate heat dissipation through natural convection around the enclosure.

- Mark removable stone units that provide junction box access on underside with permanent identification

- Position transformers in accessible locations with tool clearance for service work

- Create scaled as-built drawings showing exact conduit routing and junction box locations

- Install tracer wire along conduit runs to facilitate future location with electronic detection equipment

- Provide owner documentation including fixture specifications, lamp replacement procedures, and control operation instructions

Common Specification Errors to Avoid

You’ll encounter recurring mistakes in patio stone lighting integration Arizona projects that compromise performance and longevity. The most common error involves specifying fixtures without accounting for substrate thermal loading — you select products based on ambient air temperature ratings while ignoring that stone surface temperatures exceed air temperature by 40-60°F. This leads to premature LED degradation and driver failure within 24-36 months rather than achieving 50,000+ hour design life.

Another frequent mistake occurs when you install conduit after base compaction rather than coordinating electrical rough-in with base preparation. Trenching through compacted base creates voids and discontinuities that compromise structural integrity and create differential settlement over time. You’ll see this error manifest as sunken paving areas along conduit routes within 18-24 months of installation as base materials consolidate into trenched areas.

Inadequate voltage drop calculations lead to dim fixtures at circuit endpoints and color temperature shifts between fixtures near and far from transformers. You need to calculate voltage drop for actual circuit routing distances, not straight-line dimensions, and upsize wire gauge when calculations indicate voltage drop exceeding 8% of nominal system voltage. The cost of oversized wire represents minor expense compared to replacement costs when you discover inadequate wire gauge after installation is complete.

Final Considerations

Your professional specification process for patio stone lighting integration Arizona projects requires you to synthesize thermal performance requirements, electrical safety standards, and material compatibility considerations into cohesive installation documents. You need to move beyond generic fixture selection and address substrate-specific thermal loading, regional climate extremes, and long-term serviceability provisions. The installations that achieve 20+ year performance life share common characteristics — you’ll find appropriate fixture thermal ratings, properly sized electrical infrastructure, coordinated base preparation, and planned maintenance access in every successful project.

When you evaluate material options and lighting strategies, you should prioritize system integration over component selection. The best fixture performs poorly when installed with inadequate wire gauge or insufficient burial depth. Conversely, modest fixtures specified with appropriate thermal derating and proper installation methodology outperform premium products installed without attention to environmental loading factors. Your design decisions during the planning phase establish whether the system succeeds or requires premature replacement. For additional installation insights addressing water management in Arizona patio installations, review Proper grading specifications for patio stone installations in Arizona before you finalize your project documentation and begin construction activities. Spanish colonial designs use Citadel Stone’s historic courtyard paving in Arizona terracotta tones.