When you’re planning patio installations across Arizona’s extreme climate zones, patio stone joint spacing Arizona requirements become critical to long-term performance. You’ll face temperature swings exceeding 60°F daily in summer, surface temperatures reaching 160°F, and thermal expansion forces that standard joint spacing simply can’t accommodate. Your joint spacing decisions determine whether you’re specifying a 20-year installation or scheduling remediation work within five years.

The challenge isn’t just heat—it’s the combination of intense UV exposure, minimal humidity, and rapid thermal cycling that creates unique expansion dynamics. You need to understand how patio stone joint spacing Arizona specifications differ fundamentally from temperate climate standards, where generic 3/16″ spacing might suffice. In desert environments, you’re managing materials that expand aggressively during 14-hour solar exposure periods, then contract rapidly after sunset.

Professional specifications require you to account for substrate interaction, material composition, surface color, and site-specific solar exposure patterns. When you evaluate patio stone gap requirements Arizona projects demand, you’re balancing structural integrity against aesthetic preferences while ensuring drainage performance isn’t compromised. This guide provides the field-tested insights you need to specify joint spacing that performs across Arizona’s diverse microclimates, from Yuma’s low-desert extremes to Flagstaff’s high-elevation freeze-thaw cycles.

Thermal Expansion Fundamentals Desert Environments

Arizona’s thermal environment creates expansion coefficients you won’t encounter in moderate climates. When you specify materials for Phoenix or Tucson installations, you’re dealing with surface temperature differentials that drive expansion rates 40-60% higher than manufacturer laboratory data suggests. The 160°F surface temperatures common during June through August translate to linear expansion ranging from 0.08″ to 0.14″ per 10-foot run, depending on material composition and color.

You need to understand that thermal expansion isn’t uniform across the installation. South and west-facing areas experience 25-30% greater expansion than north-facing sections due to prolonged solar exposure. Your patio stone spacing standards Arizona specifications must account for this directional variance—uniform joint spacing across the entire installation creates stress concentrations in high-exposure zones. Professional practice requires you to increase joint width by 15-20% in areas receiving more than 8 hours of direct summer sun.

The material composition directly affects your joint spacing calculations. Dense, low-porosity materials exhibit higher thermal expansion coefficients—typically 5.8 to 6.4 × 10⁻⁶ per °F—while higher-porosity materials range from 4.8 to 5.4 × 10⁻⁶ per °F. When you calculate patio stone joint spacing Arizona requirements, you’ll find that darker materials require 20-25% wider joints than lighter colors due to higher heat absorption. A charcoal-colored paver reaching 165°F expands significantly more than a cream-colored unit at 140°F, even when they’re the same composition.

Minimum Joint Width Specifications

Your baseline joint width for Arizona installations should start at 1/4″ for standard residential applications, not the 3/16″ you might specify elsewhere. This isn’t arbitrary—field performance data from installations across the Southwest demonstrates that 3/16″ joints in high-heat environments lead to compression stress within 18-36 months. You’ll see edge spalling, lippage development, and premature joint sand erosion when joints are undersized for thermal conditions.

When you’re working with large-format units exceeding 24″ in any dimension, you need to increase minimum joint width to 5/16″. The relationship between unit size and expansion force isn’t linear—larger units generate proportionally greater stress at joint interfaces. For guidance on coordinating these specifications with other paving considerations, see our patio paving specialists for comprehensive technical support across material selection decisions.

Your specifications should address these minimum widths by exposure category:

- You need 1/4″ joints for areas receiving less than 6 hours direct summer sun

- Your spacing should increase to 5/16″ for 6-9 hours of solar exposure

- You must specify 3/8″ joints for areas with 9+ hours direct sun or reflective heat sources

- You should use 7/16″ spacing adjacent to structures with high thermal mass that radiates stored heat

The warehouse lead times for custom joint width projects typically run 2-3 weeks longer than standard specifications, so you need to factor this into your project timeline. When you’re coordinating material delivery with installation schedules, verify that your fabricator can meet dimensional tolerances—joint width consistency depends on edge precision remaining within ±1/32″.

Expansion Joint Placement Requirements

Beyond individual joint spacing, you need to incorporate dedicated expansion joints at regular intervals across large installations. These aren’t the same as standard jointing—you’re creating deliberate gaps filled with compressible material that accommodate cumulative expansion across multiple units. Your patio stone expansion joints Arizona installations require should be placed every 12-15 feet in open-field layouts, decreasing to 10-12 feet when installations abut structures or other fixed elements.

You’ll need to adjust expansion joint frequency based on material color and composition. Dark materials require expansion joints every 10-12 feet maximum, while lighter colors can extend to 15-18 feet. When you’re specifying mixed-color installations with distinct pattern zones, treat each color zone independently for expansion joint calculations—the differential expansion between adjacent color zones creates stress concentrations that standard jointing can’t manage.

Your expansion joint width should measure 1/2″ minimum, filled with closed-cell foam backer rod compressed to 75-80% capacity, topped with flexible polymeric sand or color-matched sealant. The backer rod serves as your primary expansion accommodation mechanism—it must compress without extruding under maximum thermal expansion conditions. You should specify backer rod diameter 25-30% larger than joint width to ensure proper compression fit.

- You need expansion joints along all fixed perimeter edges within 6″ of structures

- Your layout should include expansion joints perpendicular to primary sun exposure paths

- You must coordinate expansion joints with substrate control joints in concrete bases

- You should extend expansion joints through the full depth of the setting bed

Jointing Material Selection Criteria

The material you specify for filling joints matters as much as the joint width itself. Traditional silica sand fails in Arizona’s extreme conditions—it compacts excessively under thermal cycling, washes out during monsoon events, and provides insufficient resistance to ant colonization. You need polymeric sanding products specifically formulated for high-temperature performance, with activation chemistry that remains stable above 140°F.

When you evaluate polymeric sand options, verify the product maintains joint stabilization after exposure to 150°F surface temperatures. Standard polymeric formulations designed for temperate climates often soften and fail when subjected to prolonged desert heat. Your specification should require products with documented performance testing at sustained temperatures exceeding 145°F for minimum 72-hour periods.

You’ll encounter trade-offs between polymeric sand and flexible sealants for expansion joints. Polymeric products provide superior permeability for drainage while maintaining unit interlock, but they require replacement every 5-7 years as UV exposure degrades binding polymers. Flexible sealants offer 10-15 year service life but create impermeable barriers that can trap subsurface moisture. Your patio stone jointing techniques Arizona professionals employ typically use polymeric sand for standard joints and reserve sealants for dedicated expansion joints and perimeter applications.

- You should specify polymeric sand with minimum 140°F thermal stability ratings

- Your sealant selection must include products with Shore A hardness between 25-35 for adequate flexibility

- You need UV-resistant formulations rated for minimum 1,200 hours QUV-A exposure without degradation

- You must verify joint sand color stability across temperature ranges to maintain aesthetic consistency

Substrate Preparation Considerations

Your patio stone gap requirements Arizona installations demand start with substrate conditions that directly affect joint performance. When you’re working over compacted aggregate bases, the base must achieve 95% modified Proctor density to prevent differential settlement that closes joints unevenly. Inadequate base compaction allows units to settle at different rates, creating joint width variations that compromise the entire spacing system you’ve specified.

The interaction between base material and joint spacing becomes critical in clay-heavy soils common across central Arizona. These soils exhibit expansion coefficients during moisture cycling that can rival thermal expansion effects. You need to specify base depths extending minimum 6″ below native soil, filled with non-expansive aggregate that maintains dimensional stability. When native soils test above 15% plasticity index, increase your base depth to 8-10″ and incorporate geotextile separation layers.

You should verify that truck access to your site accommodates delivery of proper base materials—inadequate access often forces substitution of substandard aggregates that compromise long-term joint stability. When you coordinate material delivery logistics, confirm that base installation timing allows proper moisture conditioning and compaction verification before paver placement begins.

Installation Technique Impacts

The installation method you specify directly affects how well your designed joint spacing performs long-term. Wet-set installations over concrete substrates require different jointing approaches than dry-laid systems over aggregate bases. When you specify wet-set applications, you’re dealing with mortar joints that must accommodate thermal movement without cracking—this requires joint widths 30-40% wider than equivalent dry-laid specifications.

Your wet-set joint fill should use modified mortars with polymer additives that maintain flexibility across temperature extremes. Standard cement-based mortars crack under Arizona’s thermal cycling within 2-3 years. You need to specify Type S mortar modified with acrylic or latex polymers at manufacturer-recommended ratios, providing flexural strength while maintaining adequate compressive capacity. The mortar consistency matters—you should require flowable consistency that completely fills joints without voids, but not so fluid that it stains paver faces during installation.

For dry-laid installations, you’ll achieve better thermal performance, but you must ensure proper edge restraint to prevent joint width creep. Perimeter restraints should be mechanically anchored at 24″ maximum intervals using anchors extending minimum 8″ into base material. When edge restraint fails or shifts, thermal expansion forces gradually widen joints beyond design specifications, leading to stability loss and accelerated joint sand erosion.

Color-Specific Spacing Adjustments

Material color creates significant variation in required joint spacing due to differential heat absorption. When you specify dark charcoals, chocolates, or black materials, you’re dealing with surface temperatures 20-25°F higher than cream, tan, or white alternatives. This temperature differential translates directly to expansion differences requiring wider joints—your dark material patio stone joint spacing Arizona specifications should increase by minimum 1/32″ compared to light colors in identical applications.

You need to account for color-specific expansion when designing mixed-color patterns or borders. A dark border surrounding a light-colored field creates differential expansion that concentrates stress at the color transition. Your specification should include transition expansion joints at all color change locations, even when the total installation area wouldn’t otherwise require intermediate expansion joints. These transition joints prevent the differential expansion forces from causing edge spalling or unit displacement at pattern boundaries.

- You should increase joint width by 1/32″ for materials with light reflectance values below 35%

- Your specifications need 1/16″ additional spacing for black or very dark materials in high-exposure areas

- You must incorporate transition expansion joints at all distinct color change boundaries

- You need to consider how adjacent light-colored structures reflect additional heat onto dark paving surfaces

Monsoon Season Drainage Integration

Arizona’s monsoon season presents unique challenges for patio stone spacing standards Arizona professionals must address. While thermal expansion drives your minimum joint width requirements, those same joints must handle intense rainfall events delivering 1-2 inches in under 30 minutes. Your joint spacing system needs to function as primary drainage infrastructure, channeling water through the paver surface into the base material without creating surface ponding or joint erosion.

When you design joint spacing for drainage performance, you’re balancing competing requirements. Wider joints improve drainage capacity but reduce interlock and accelerate joint material erosion during high-velocity water flow. Your optimal balance point typically lands at 1/4″ to 5/16″ for standard joints, providing adequate drainage while maintaining structural integrity. You should specify 2% minimum surface slope to encourage water movement toward designated drainage zones rather than relying solely on joint permeability.

The polymeric sand you specify must withstand erosive forces during monsoon events without washing from joints. Lower-quality polymeric products fail within one or two monsoon seasons, requiring complete joint refilling. You need products with documented erosion resistance testing simulating high-velocity water flow—look for products tested at flow rates exceeding 5 gallons per minute per linear foot of joint without material loss.

Citadel Stone Manufactured Bluestone Pavers Arizona Applications

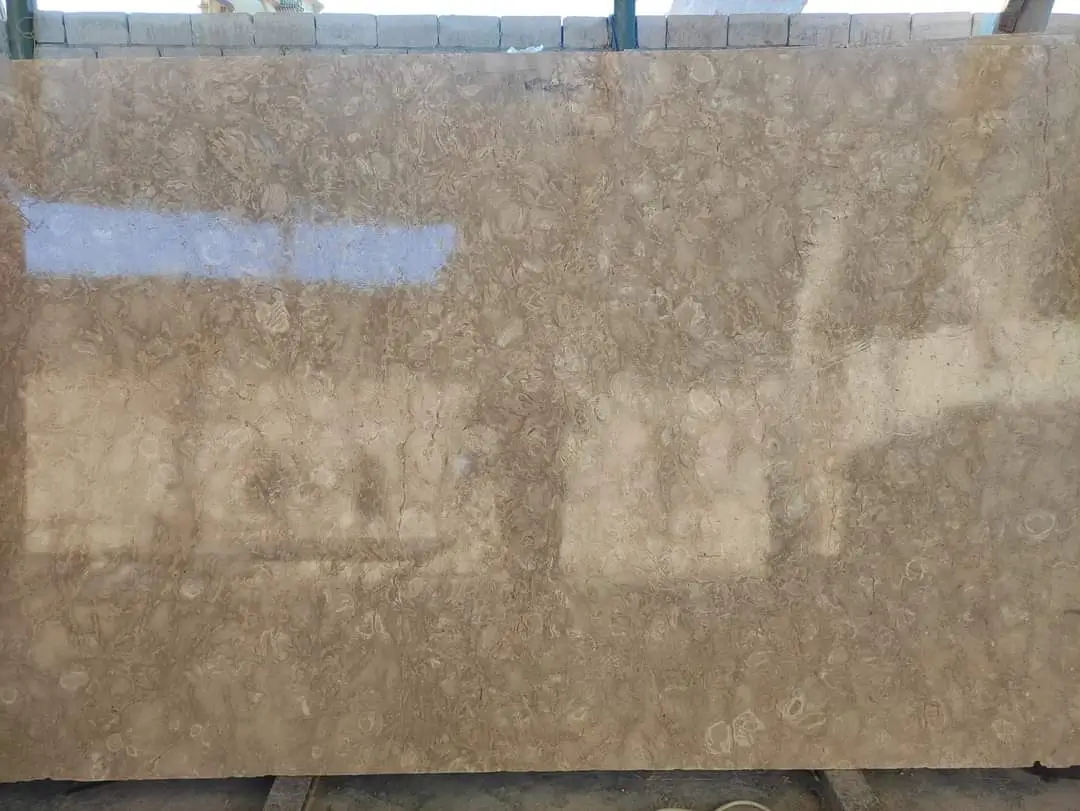

When you consider manufactured bluestone pavers in Arizona for your desert installations, you’re evaluating materials specifically engineered to address the thermal challenges discussed throughout this guide. At Citadel Stone, we manufacture composite paving materials with controlled thermal expansion properties that simplify joint spacing specifications while delivering superior performance. This section outlines how you would approach patio stone gap requirements Arizona projects demand when specifying these advanced materials across six representative cities.

Our manufactured bluestone technology provides consistent thermal expansion coefficients around 5.1 × 10⁻⁶ per °F—notably lower than many natural stone alternatives—which allows you to use more conservative joint spacing while maintaining long-term stability. You would find that the material’s engineered porosity provides excellent drainage characteristics during monsoon season while resisting the efflorescence common in natural limestone products exposed to Arizona’s alkaline soils. The manufacturing process creates dimensional precision within ±1/32″, ensuring the joint spacing you design during specification actually translates to field conditions.

Phoenix Thermal Considerations

In Phoenix applications, you would specify 1/4″ joint spacing for manufactured bluestone installations in standard residential settings, increasing to 5/16″ for commercial applications with large-format units or high solar exposure. The urban heat island effect in Phoenix adds 8-12°F to ambient temperatures compared to surrounding desert, which translates to increased thermal stress on paving materials. You would need to account for this additional heat load in your joint spacing calculations, particularly for downtown or dense suburban installations where surrounding structures and paving create heat concentration. Your expansion joint placement should occur every 12-14 feet in open areas, decreasing to 10-12 feet adjacent to buildings or other fixed elements. The valley’s minimal freeze-thaw cycling allows you to focus exclusively on thermal expansion without competing cold-weather requirements.

Tucson Desert Performance

Tucson’s slightly higher elevation creates marginally lower summer temperatures than Phoenix, but you would still specify minimum 1/4″ joints for manufactured bluestone applications. The city’s soil conditions include higher caliche content than Phoenix, which affects base preparation more than joint spacing directly. You should account for Tucson’s stronger monsoon season—the city averages 6-8 major rainfall events annually compared to Phoenix’s 4-6—which places higher demands on joint drainage capacity. Your polymeric sand selection would emphasize erosion resistance to withstand these more frequent high-intensity rainfall events. When you specify for Tucson’s historic districts downtown, account for reflective heat from adjacent stucco structures that can add 15-20°F to localized surface temperatures. At Citadel Stone, we would recommend increasing joint width to 5/16″ in these microclimate conditions.

Scottsdale Luxury Applications

Scottsdale installations often emphasize aesthetics alongside performance, and you would specify manufactured bluestone for applications where consistent color and minimal joint visibility create desired contemporary appearances. Your joint spacing would remain at 1/4″ minimum, but you could explore precision installation techniques that maintain joints at the lower end of acceptable ranges—closer to 1/4″ than 5/16″—due to the material’s controlled expansion properties. The city’s north Scottsdale areas experience desert conditions similar to Phoenix, while southern areas encounter additional urban heat effects. You would adjust your expansion joint frequency based on these microclimates, using 12-foot spacing in northern desert applications and 10-foot spacing in denser southern neighborhoods. Premium projects might incorporate nearly invisible expansion joints using color-matched flexible sealants that maintain clean aesthetic lines while accommodating thermal movement.

Flagstaff Freeze-Thaw Balance

Flagstaff presents Arizona’s most complex patio stone expansion joints Arizona specification challenge because you must balance thermal expansion against freeze-thaw durability requirements. At 7,000 feet elevation with 100+ annual freeze-thaw cycles, you would specify manufactured bluestone with enhanced porosity specifications to accommodate ice formation. Your joint spacing would start at 5/16″ minimum—wider than low-desert applications—to provide expansion accommodation in both directions. The material’s engineered porosity allows moisture to escape rather than accumulating in pore structures where freezing would cause spalling. You should specify expansion joints every 10-12 feet maximum in Flagstaff installations, using compressible backer rod that remains flexible at temperatures down to -10°F. Winter surface temperatures reaching -20°F during cold snaps create contraction forces comparable to summer expansion, requiring your joint system to accommodate bidirectional movement across a 180°F annual range.

Sedona Red Rock Context

When you specify manufactured bluestone in Sedona, you’re often coordinating with the area’s distinctive red rock aesthetic context. Your joint spacing would follow standards similar to Phoenix—1/4″ minimum for standard applications—but you would pay particular attention to color selection and how joint sand color integrates with both the paver color and surrounding landscape. Sedona’s elevation around 4,500 feet creates temperature ranges between Phoenix and Flagstaff, with summer highs reaching 100°F but winter lows occasionally dropping below 20°F. You would account for approximately 30-40 freeze-thaw cycles annually in your material selection, though thermal expansion remains the dominant concern. The red soil common throughout Sedona can stain light-colored joint materials, so you should specify polymeric sand with stain-inhibiting properties or select darker joint colors that won’t show discoloration.

Yuma Extreme Heat Protocols

Yuma represents Arizona’s most extreme thermal environment for patio stone jointing techniques Arizona specifications must address. Summer temperatures consistently exceed 110°F, with surface temperatures on dark materials reaching 170°F. You would specify manufactured bluestone in lighter colors for Yuma applications and increase joint spacing to 5/16″ as baseline, expanding to 3/8″ for south and west exposures. The city’s position along the Colorado River creates slightly higher humidity than other Arizona deserts—still low at 20-30% during summer but enough to affect polymeric sand activation and performance. Your expansion joint frequency should increase to every 10-12 feet maximum due to extended high-temperature exposure periods. Yuma experiences Arizona’s longest summer season, with temperatures exceeding 100°F from May through September, meaning materials remain in expanded state for prolonged periods. You need to ensure your joint spacing accommodates maximum expansion rather than average conditions.

Common Specification Mistakes

You’ll encounter recurring errors in patio stone joint spacing Arizona specifications that lead to premature failure. The most common mistake involves directly applying manufacturer spacing recommendations developed for temperate climates. When you see generic 3/16″ joint spacing in product literature, recognize that this applies to moderate temperature ranges—you need to increase these specifications for Arizona conditions. Failure to adjust for local climate conditions results in compression stress, edge spalling, and unit displacement within 3-5 years.

Another frequent error occurs when you specify uniform joint spacing across installations with varying solar exposure. Your south and west-facing areas require wider joints than north-facing sections, yet many specifications call for consistent spacing throughout. This oversight creates stress concentrations in high-exposure zones while leaving low-exposure areas with unnecessarily wide joints that compromise aesthetic appearance. You should create zoned specifications that acknowledge exposure variation across the installation.

- You need to avoid specifying standard polymeric sand not rated for high-temperature performance

- Your specifications must not overlook expansion joint requirements at color transition boundaries

- You should never specify joint width without accounting for material color and its heat absorption implications

- You must not assume manufacturer dimensional tolerances without verification—poor edge precision makes designed joint spacing impossible to achieve

- You need to specify perimeter restraint systems adequate for thermal expansion forces your joints will accommodate

Warehouse inventory planning presents another common oversight. When you specify non-standard joint widths requiring custom fabrication, you need lead times extending 3-4 weeks beyond stock materials. Failure to account for these timelines during project planning creates schedule compression that forces specification compromises or material substitutions undermining your joint spacing design.

Maintenance Requirements Joint Longevity

Even properly specified patio stone spacing standards Arizona guidelines recommend require ongoing maintenance to sustain performance. You should establish maintenance protocols that include annual joint inspection following monsoon season, when erosion and washout are most likely to occur. Your maintenance specification needs to address polymeric sand replenishment every 5-7 years as UV degradation breaks down binding polymers. This isn’t failure—it’s expected lifecycle maintenance that sustains the joint system you’ve designed.

When you develop maintenance plans, emphasize that joint sand should be maintained at 85-95% capacity. Overfilling creates surface mess and doesn’t improve performance, while underfilling below 80% allows lateral unit movement that progressively widens joints beyond design specifications. You need to educate property owners that joint maintenance is comparable to other exterior maintenance tasks—it requires periodic attention but prevents major remediation expenses.

Your maintenance protocols should include power washing guidelines that protect joint materials. High-pressure washing perpendicular to joint lines erodes polymeric sand rapidly, requiring premature replacement. When you specify maintenance procedures, limit pressure to 1,500 PSI maximum and require washing parallel to joint orientation. These precautions extend polymeric sand service life from 5-7 years to 8-10 years in many installations.

Performance Verification Methods

You need post-installation verification procedures confirming that your designed joint spacing translates to field conditions. Your quality control protocol should include random joint width measurements at 20-30 locations across the installation, verified with feeler gauges or digital calipers. When measurements reveal variance exceeding ±1/32″ from specifications, you must determine whether the issue stems from material dimensional tolerance, installation technique, or improper base preparation.

Thermal performance verification requires you to inspect installations during peak temperature conditions—ideally during afternoon hours in July or August when materials reach maximum expansion. You should look for compression indicators including edge chipping, corner spalling, or units that rock when walked upon. These symptoms indicate inadequate joint spacing for actual thermal conditions. When you identify compression stress, remediation requires removing affected units, widening joints to appropriate specifications, and reinstalling with proper spacing.

Your verification should extend to drainage performance testing during or immediately after significant rainfall. When you observe surface ponding lasting more than 15 minutes after rain cessation, investigate whether joint materials have become clogged or if joint spacing is inadequate for drainage requirements. Proper joint spacing combined with appropriate polymeric sand should drain surface water within 5-10 minutes after rainfall ends.

Final Integration Considerations

Your professional patio stone joint spacing Arizona specifications require integrating thermal expansion accommodation with aesthetic expectations, drainage requirements, and long-term maintenance realities. When you balance these competing factors, you’ll find that slightly wider joints—1/4″ to 5/16″ rather than 3/16″—provide superior performance across all criteria despite initial concerns about visual appearance. The reality is that properly filled joints at these widths become nearly invisible from normal viewing distances while delivering the expansion accommodation Arizona’s climate demands.

You should coordinate your joint spacing specifications with overall project timelines, accounting for material lead times when custom fabrication is required. The warehouse stocking for standard products typically provides 5-10 day delivery windows, while custom specifications extend to 3-4 weeks. When you’re managing project schedules, build these timelines into your procurement planning to avoid specification compromises driven by schedule pressure rather than performance requirements.

The emerging technology in manufactured paving materials offers you controlled expansion properties that simplify Arizona specifications while maintaining natural stone aesthetics. For additional guidance on material selection that complements proper joint spacing, review Selecting appropriate patio stone thickness for Arizona desert climate before you finalize your project specifications. Composite materials come from Citadel Stone’s innovative manufactured patio stone in Arizona technology.