Your patio installation in Arizona faces environmental challenges unlike anywhere else in North America. When you specify patio stone sealing Arizona protocols, you’re addressing sustained UV exposure that degrades unprotected surfaces within 18-24 months, thermal cycling that exceeds 60°F daily swings, and alkaline soil conditions that trigger persistent efflorescence. The difference between a maintenance-intensive surface and a low-care installation comes down to understanding how desert conditions interact with stone porosity, sealant chemistry, and regional water quality.

You’ll encounter three primary degradation mechanisms in Arizona installations: UV-induced sealant breakdown, thermal stress cracking in porous stone pavers, and subsurface moisture migration through inadequately sealed joints. Professional specification addresses all three simultaneously rather than treating them as isolated variables. When you plan your maintenance program, you need to account for how Phoenix’s 4,000+ annual sunshine hours affect polymer degradation rates compared to coastal or mountain environments where cloud cover provides periodic UV relief.

Sealing Requirements for Desert Climate Installations

Your sealing protocol must address Arizona’s extreme conditions with material-specific approaches. When you work with porous stone pavers, you’re dealing with absorption rates between 3-8% by volume, meaning water penetrates 1/8 to 1/4 inch below the surface during typical monsoon events. This subsurface saturation creates two problems: it provides a reservoir for efflorescence precursors, and it establishes conditions for thermal stress when surface temperatures spike to 160°F while subsurface layers remain 40°F cooler.

You should specify penetrating sealers rather than topical coatings for most Arizona applications. Penetrating formulations migrate into the pore structure and create hydrophobic conditions without forming a surface film that debonds under thermal stress. Your specification needs to address cure time requirements — most penetrating sealers require 72-96 hours at temperatures between 50-90°F, which limits your application windows to October through April in Phoenix and Tucson, or May through September in Flagstaff.

- You need to verify substrate moisture content below 4% before sealer application

- Your chosen sealer must maintain effectiveness at surface temperatures exceeding 150°F

- You should plan for reapplication intervals of 24-36 months in full-sun exposures

- UV-stable formulations prevent the yellowing that occurs with standard acrylic sealers after 18 months

When you evaluate sealer products, focus on breathability ratings measured in perms. Arizona installations require high-perm sealers (15+ perms) that allow subsurface moisture to escape as vapor while preventing liquid water intrusion. Low-perm sealers trap subsurface moisture, creating conditions for spalling when thermal expansion generates internal pressures exceeding 500 PSI during afternoon heating cycles.

Cleaning Porous Stone Pavers in Alkaline Soil Conditions

Cleaning porous stone pavers requires understanding how Arizona’s alkaline soils (pH 7.8-9.2) interact with moisture migration. You’ll see white crystalline deposits appearing 6-18 months after installation as groundwater carries dissolved salts upward through capillary action. These deposits aren’t surface dirt — they’re mineral precipitates that form when subsurface water evaporates at the paver surface, leaving behind calcium carbonate, sodium sulfate, and magnesium compounds.

Your cleaning approach depends on deposit type and severity. For light efflorescence, you can use pH-neutral cleaners with scrubbing to remove surface crystals. When you encounter heavy deposits or recurring patterns, you need acidic cleaners formulated specifically for removing efflorescence from stone. Standard muriatic acid works but requires careful dilution (1:10 water ratio) and thorough rinsing to prevent acid residue from etching the stone surface.

Here’s what many installers miss: cleaning removes visible deposits but doesn’t address the underlying moisture migration causing them. After you complete cleaning, you must implement measures to reduce subsurface moisture. This typically involves improving drainage around the installation perimeter and applying penetrating sealers that reduce capillary action. You’ll find that installations with properly compacted aggregate base layers and effective edge drainage experience 70-80% less efflorescence than those with inadequate base preparation.

- You should test cleaners on inconspicuous areas before full application

- Removing efflorescence from stone requires addressing moisture sources, not just surface cleaning

- Your cleaning schedule should align with seasonal patterns — monsoon season typically triggers new efflorescence appearance

- Pressure washing above 1,200 PSI can damage porous stone pavers and widen joints excessively

When you clean porous stone pavers, timing matters as much as technique. You’ll achieve better results cleaning in morning hours before surface temperatures exceed 90°F. Afternoon cleaning sessions cause rapid evaporation that leaves cleaner residue and water spots, requiring additional rinses that waste time and water.

UV Protection for Pavers and Polymer Degradation Prevention

UV protection for pavers in Arizona goes beyond aesthetic concerns — it’s a structural requirement. When you evaluate sealant products, you’re looking at polymer formulations that either withstand or fail under sustained UV exposure exceeding 400 watts per square meter during peak hours. Standard acrylic sealers degrade within 18-24 months in full Arizona sun, exhibiting chalking, yellowing, and loss of water repellency that necessitates complete removal and reapplication.

You should specify UV-stable formulations incorporating hindered amine light stabilizers (HALS) or UV absorbers that protect the base polymer from photodegradation. These additives work by either absorbing UV energy before it breaks polymer bonds or by stabilizing free radicals that form during UV exposure. Professional-grade sealers maintain effectiveness for 36-48 months in Arizona conditions, compared to 12-18 months for consumer-grade products without UV protection.

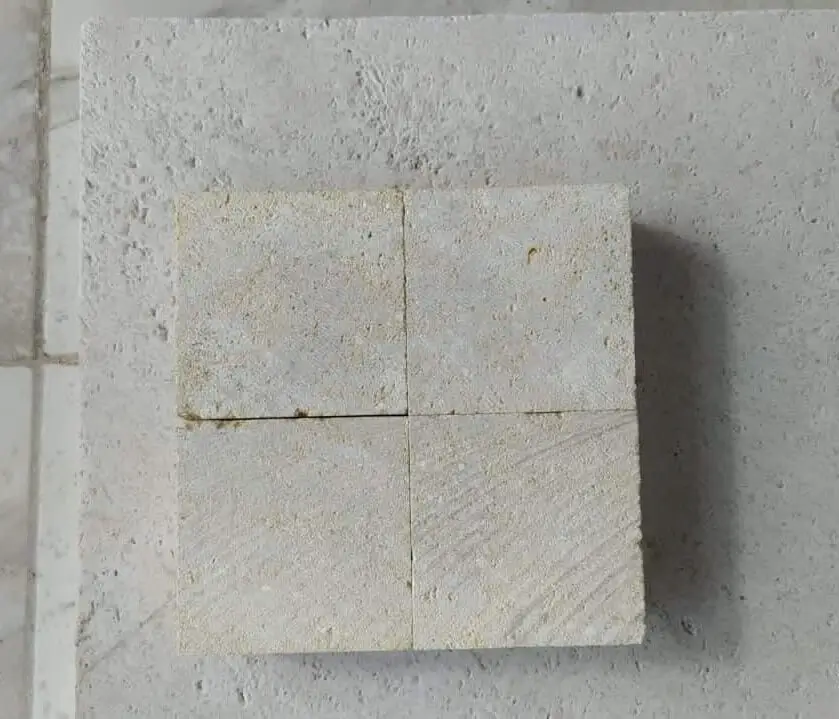

The material composition of our manufactured patio blocks affects how you approach UV protection protocols. Natural stone with high quartz content exhibits better inherent UV resistance than softer sedimentary materials, but all porous substrates benefit from UV-stable sealers that prevent surface oxidation and color fading.

- You need to verify sealer UV stability through ASTM G154 accelerated weathering test data

- Your maintenance program should include annual inspections for signs of UV degradation

- You’ll see chalking as the first visible indicator that sealer replacement is overdue

- UV protection for pavers in shaded areas requires less frequent reapplication than full-sun exposures

Thermal Cycling Effects on Joint Stability and Long-Term Performance

Your Arizona installation experiences thermal cycling that most other regions never encounter. When surface temperatures swing from 55°F at sunrise to 160°F by mid-afternoon, you’re generating expansion and contraction cycles that stress both the paver material and joint systems. This movement is measurable — a 20-foot patio section can expand 1/4 inch during peak heating, then contract the same amount overnight.

You need to account for this movement in your joint design and maintenance program. Joint sand compaction changes cyclically as pavers expand and contract, creating voids that accelerate sand loss during monsoon rains or when you clean with pressure washers. Professional installations maintain joint sand at 90-95% of depth capacity, leaving expansion space at the top 1/4 inch. When you overfill joints initially, thermal expansion pushes sand upward and outward, leading to 30-40% sand loss in the first year.

Your long-term maintenance program should include joint sand replenishment on an annual basis, preferably in late spring after winter thermal contraction has stabilized but before monsoon season begins. You’ll find that polymeric sand products offer better retention than conventional silica sand, but they require proper installation technique — the sand must be completely dry when applied, thoroughly compacted, then misted (not soaked) to activate the polymer binder.

Efflorescence Patterns and Regional Water Quality Variations

Removing efflorescence from stone becomes a recurring maintenance issue when you don’t address the relationship between regional water quality and mineral deposition patterns. Arizona’s water supply varies dramatically by region — Phoenix relies heavily on Colorado River water with total dissolved solids (TDS) around 400-600 ppm, while Tucson uses a mix of Colorado River and local groundwater with TDS often exceeding 300-500 ppm. These dissolved minerals become the source material for efflorescence when water migrates through your paver installation.

You’ll encounter three distinct efflorescence types in Arizona: primary efflorescence from paver manufacturing (appears within first 6 months), secondary efflorescence from grouting or base materials (appears 6-18 months post-installation), and recurring efflorescence from ongoing moisture migration (continues indefinitely without intervention). Your treatment approach differs for each type. Primary efflorescence typically resolves with initial cleaning and doesn’t recur. Secondary efflorescence requires identifying and replacing contaminated base materials. Recurring efflorescence demands comprehensive moisture management including drainage improvement and sealer application.

When you specify materials for warehouse delivery to Arizona projects, you should request low-alkali cement content in manufactured products to minimize primary efflorescence potential. Natural stone products don’t carry this variable, but they introduce different considerations — limestone and travertine contain calcium carbonate that can leach and redeposit as white film, particularly when you use acidic cleaners that dissolve surface material.

- You should test irrigation water for TDS content when planning maintenance protocols

- Removing efflorescence from stone in hard-water regions requires more frequent intervention

- Your drainage design must account for monsoon intensity — 2 inches per hour isn’t uncommon

- Desert landscape maintenance programs should include subsurface moisture monitoring

Seasonal Maintenance Protocols and Climate Zone Adjustments

Desert landscape maintenance requirements change dramatically across Arizona’s elevation gradient. When you maintain installations in Yuma (elevation 141 feet, average high 107°F), you’re addressing different challenges than Flagstaff installations (elevation 6,909 feet, average high 66°F). Your maintenance calendar needs to reflect these regional variations rather than applying uniform protocols statewide.

You should schedule major maintenance interventions during optimal weather windows. For Phoenix, Tucson, and Yuma, this means October through April when temperatures stay below 90°F and humidity remains low enough for proper sealer curing. When you attempt sealing during summer months in these cities, you’ll encounter flash curing where sealers dry on the surface before penetrating properly, reducing effectiveness by 40-60%. For Flagstaff and Sedona, your maintenance window shifts to May through September when temperatures support proper chemical reactions and overnight freezing doesn’t threaten wet sealers.

Your cleaning schedule should align with seasonal soil moisture patterns. Pre-monsoon cleaning (May-June in most regions) removes accumulated dust and prepares surfaces for summer weather. Post-monsoon cleaning (September-October) addresses any new efflorescence or organic growth that appeared during the wet season. You’ll find that cleaning porous stone pavers immediately after monsoon events is counterproductive — surfaces remain damp for 48-72 hours after heavy rains, and cleaning wet pavers just pushes water deeper into the pore structure.

Pressure Washing Damage Prevention and Proper Technique

You need to understand that pressure washing, while effective for removing surface contamination, can cause significant damage when performed incorrectly. The primary risks include joint sand displacement, surface erosion on softer stones, and forced water intrusion that increases efflorescence potential. When you exceed 1,200 PSI on porous stone pavers, you’re generating enough force to erode surface texture and widen joints beyond design specifications.

Your pressure washing technique should emphasize lower pressure (800-1,000 PSI) with higher volume rather than high pressure with focused streams. You’ll achieve better cleaning results using 25-40 degree fan tips held 12-18 inches from the surface, making multiple passes if needed. When you use narrow-angle tips or move too close to the surface, you create erosion patterns that become permanent surface damage.

- You should avoid pressure washing during peak heat hours when rapid drying leaves mineral deposits

- Your equipment setup must include pressure regulation to prevent exceeding safe limits

- You need to plan for joint sand replenishment after any pressure washing session

- Cleaning porous stone pavers with hot water improves organic stain removal without increasing pressure

Chemical injection through pressure washing equipment allows you to apply cleaning solutions at consistent dilution ratios, but you must verify chemical compatibility with both the stone material and existing sealers. Some acids react with sealers and require complete sealer removal before use. When you encounter this situation, your maintenance becomes a complete restoration rather than routine cleaning.

Organic Growth Control in Desert Environments

You might assume organic growth isn’t a concern in Arizona’s arid climate, but you’d be overlooking how irrigation systems and monsoon moisture create favorable conditions for algae, moss, and lichen. These organisms establish in paver joints and shaded areas where moisture persists longer than exposed surfaces. When you see green or black discoloration in joints or along north-facing edges, you’re looking at organic growth that requires specific treatment protocols.

Your approach to organic growth control depends on growth type and extent. Light algae responds to sodium hypochlorite solutions (pool chlorine diluted 1:4 with water) applied during cooler morning hours and allowed to dwell for 15-20 minutes before rinsing. When you encounter heavier moss or lichen growth, you’ll need stronger concentrations and mechanical agitation with stiff brushes. Pressure washing alone often spreads spores and creates conditions for faster regrowth.

Prevention proves more effective than treatment. When you apply quality sealers with antimicrobial additives, you create surface conditions that inhibit organic growth establishment. Your maintenance program should include annual sealer reapplication in problem areas even when general wear doesn’t warrant full-surface resealing. You’ll find that consistently sealed surfaces show 80-90% less organic growth than unsealed areas.

Stain Removal Techniques for Oil, Rust, and Mineral Deposits

Removing efflorescence from stone represents just one category of stain you’ll encounter in Arizona installations. Oil stains from vehicles or cooking equipment, rust stains from metal furniture or irrigation components, and tannin stains from desert vegetation all require specific treatment approaches. When you attempt universal stain removal with single-product solutions, you’ll achieve poor results and potentially damage the stone surface.

You should maintain a stain-specific cleaning kit that includes alkaline degreasers for oil stains, oxalic acid or specialized rust removers for iron staining, and poultice materials for deep extraction of absorbed contaminants. Poultice application works by drawing stains from within porous stone pavers through capillary action — you mix absorbent powder (diatomaceous earth or sepiolite) with appropriate solvent, apply 1/4 to 1/2 inch thick over the stain, cover with plastic to slow drying, and allow 24-48 hours for extraction.

- You need to identify stain type before selecting treatment chemicals

- Your treatment effectiveness depends on how quickly you address new stains

- You should test all stain removers on inconspicuous areas first

- Oil stains that penetrate beyond 1/4 inch depth may require professional restoration

Sealer Selection Based on Breathability and Performance Requirements

Your sealer selection process needs to balance water repellency, vapor permeability, UV stability, and application characteristics. When you evaluate products, you’re comparing formulations that range from low-solids penetrating sealers (5-15% active ingredients) to high-solids coating sealers (30-50% active ingredients). Arizona conditions generally favor penetrating sealers in the 12-20% solids range — enough active ingredient to provide durable protection without forming problematic surface films.

You should request technical data sheets that specify vapor permeability in perms and water vapor transmission rate. Professional-grade sealers maintain permeability above 15 perms while reducing water absorption by 85-95%. When you choose sealers with permeability below 10 perms, you’re creating conditions for trapped moisture and potential spalling during thermal stress events. The warehouse typically stocks both high-perm and low-perm options, so you need to specify requirements clearly in your material orders.

Solvent-based versus water-based formulations present different advantages. Solvent-based sealers penetrate deeper (1/4 to 3/8 inch) and cure more reliably in variable conditions, but they require VOC compliance verification and create application hazards from flammable vapors. Water-based formulations offer safer handling and lower environmental impact but require more precise application conditions — you can’t apply them when temperatures drop below 50°F or rise above 90°F, and humidity must stay below 70% during curing.

Common Maintenance Mistakes and Long-Term Cost Implications

You’ll encounter several recurring mistakes in Arizona patio maintenance that create expensive repair requirements. The most costly involves delaying sealer reapplication beyond effective service life. When you allow sealers to fail completely before reapplication, you’re not just losing water repellency — you’re allowing deep moisture penetration that triggers efflorescence, supports organic growth, and creates conditions for freeze-thaw damage in higher elevation installations. The cost difference between timely resealing (every 30-36 months) versus damage repair after neglect often exceeds 400%.

Another common error involves using inappropriate cleaning chemicals. When you apply acidic cleaners to calcareous stones like limestone or travertine, you’re dissolving surface material and creating permanent etching. Your cleaning product selection must account for stone composition — siliceous stones (granite, quartzite) tolerate acids well, while calcareous stones require pH-neutral or mildly alkaline cleaners. Product labels don’t always provide adequate guidance, so you need to verify stone type before selecting cleaners.

- You should avoid high-pressure washing that displaces joint materials and requires costly repairs

- Your maintenance intervals need to match actual conditions rather than arbitrary schedules

- You must address drainage issues promptly rather than treating recurring efflorescence symptoms

- UV protection for pavers requires proactive resealing before visible degradation occurs

When you neglect joint maintenance, you’re creating conditions for progressive failure. Lost joint sand allows lateral paver movement, which creates edge chipping and lippage issues. Your repair costs escalate from simple sand replenishment ($0.50-1.00 per square foot) to releveling and edge repair ($8-15 per square foot) when you delay intervention.

Citadel Stone Experience with Artificial Stone Pavers in Arizona — Specification Guidance for Regional Applications

When you consider Citadel Stone’s artificial stone pavers in Arizona for your projects, you’re evaluating engineered materials designed specifically for extreme climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from the Sonoran Desert floor to ponderosa pine forests at 7,000-foot elevations. This section outlines how you would approach specification decisions for six representative cities, addressing the climate-specific factors that determine long-term installation success.

You need to understand that Arizona encompasses multiple climate zones with dramatically different requirements. When you specify for low-desert installations, you’re addressing sustained high temperatures and intense UV exposure. Your mountain region specifications must account for freeze-thaw cycling and winter precipitation. At Citadel Stone, we recommend analyzing climate data for your specific project location rather than applying generic Arizona specifications.

Phoenix Installation Specifications

In Phoenix, you would need to address extreme heat conditions where surface temperatures routinely exceed 160°F during June through August. Your material selection should prioritize light colors that reflect 60-70% of solar radiation rather than dark materials that exceed 180°F surface temperatures. When you plan installation timing, you’d want to schedule work between October and April when temperatures support proper adhesive curing and worker safety. You should specify UV-stable sealers rated for continuous high-temperature exposure and plan for 24-month resealing intervals in full-sun applications. Your base preparation would need to account for Phoenix’s stable soil conditions but address the thermal expansion that generates 1/4 inch of movement in 20-foot sections.

Tucson Climate Considerations

When you specify for Tucson applications, you’re working with conditions similar to Phoenix but with slightly more monsoon moisture and greater elevation (2,400 feet versus Phoenix’s 1,100 feet). You would need to emphasize drainage design that handles intense monsoon rainfall reaching 2-3 inches per hour during July and August storm events. Your sealing protocol should account for higher moisture exposure during summer months while maintaining protection against the 110°F+ temperatures common from May through September. You’d want to verify that your selected materials maintain structural integrity through daily thermal cycles exceeding 50°F and address the alkaline soils common throughout the Tucson basin.

Scottsdale High-End Specifications

Your Scottsdale specifications would typically address high-end residential and resort applications where aesthetics rank equally with performance. You’d focus on materials that maintain color stability through intense UV exposure while providing the thermal performance necessary for comfortable pool deck and patio applications. When you plan maintenance programs for Scottsdale installations, you should account for property owner expectations that demand pristine appearance year-round. You would specify premium UV-stable sealers with enhanced stain resistance and plan for professional maintenance intervals at 18-24 months rather than the 30-36 months acceptable in less-visible commercial applications.

Flagstaff Freeze-Thaw Requirements

In Flagstaff, you would address completely different environmental factors than low-desert installations. Your specifications must account for 100+ annual freeze-thaw cycles, winter precipitation totaling 100+ inches of snowfall, and sustained below-freezing temperatures from November through March. You’d need to verify that your selected materials exhibit less than 3% absorption to prevent freeze-thaw damage and specify proper slope for drainage (minimum 2% grade). When you plan sealing protocols for Flagstaff, you should focus on breathable formulations that allow subsurface moisture to escape rather than creating impermeable barriers that trap water and amplify freeze-thaw damage. You would schedule installation and maintenance work during the May-September window when temperatures consistently support proper curing.

Sedona Aesthetic Integration

When you specify for Sedona applications, you’re typically working with projects that require visual integration with the region’s distinctive red rock landscape. You would select material colors that complement rather than contrast with natural surroundings while meeting performance requirements for the 4,500-foot elevation environment. Your specifications should address moderate freeze-thaw exposure (40-60 annual cycles) and the intense UV conditions created by high elevation and clear skies. You’d want to plan for seasonal maintenance scheduling that avoids peak tourist periods when property access becomes complicated and material delivery faces delays from traffic congestion on narrow canyon roads.

Yuma Extreme Heat Protocols

Your Yuma specifications would need to address the most extreme heat conditions in Arizona, where summer temperatures exceed 110°F for 90+ days annually and surface temperatures can reach 180°F on dark materials. You should prioritize maximum solar reflectance through light-colored materials and specify installation timing strictly between November and March when conditions support worker safety and proper material handling. When you plan sealing protocols for Yuma, you’d focus on high-temperature-stable formulations and shortened reapplication intervals of 18-24 months due to accelerated UV degradation. You would need to account for the Colorado River water supply’s mineral content (TDS 600-700 ppm) in your efflorescence prevention and cleaning protocols, as this represents some of the hardest water in Arizona.

Long-Term Performance Strategies

Your successful Arizona patio maintenance program depends on implementing proactive rather than reactive protocols. When you establish regular inspection schedules (quarterly for high-traffic installations, semi-annually for residential applications), you identify developing issues while they remain inexpensive to address. You should document baseline conditions immediately after installation completion, including photographs of surface appearance, joint sand levels, and drainage performance. This documentation provides reference points for evaluating change over time and determining when intervention becomes necessary.

You need to establish relationships with qualified maintenance contractors before problems develop. When you wait until damage appears to search for service providers, you’re negotiating from a position of urgency that increases costs and reduces quality options. Your maintenance contractor selection should emphasize experience with patio stone sealing Arizona applications specifically, not general pressure washing or landscape maintenance services that lack material-specific knowledge.

- You should create written maintenance protocols specific to your installation’s materials and exposure conditions

- Your budget planning must include proactive maintenance costs rather than treating them as discretionary expenses

- You need to verify contractor insurance and licensing before authorizing work on your property

- Desert landscape maintenance expertise should include understanding of how irrigation affects hardscape performance

When you coordinate maintenance with seasonal weather patterns, you maximize effectiveness while minimizing costs. Your annual maintenance calendar should include spring inspection and cleaning (March-April for low desert, May-June for high country), monsoon damage assessment (September), and sealer condition verification (October-November). This timing allows you to address issues before they compound and ensures work occurs during optimal temperature and humidity conditions. For comprehensive guidance on related commercial applications, review Large format porcelain pavers for Arizona commercial hardscape projects before you finalize specifications for large-scale installations. Custom colors available in Citadel Stone’s varied patio stones for sale in Arizona palette.