When you evaluate Arizona Stone Fabricators for your commercial or residential paving project, you’re entering a complex landscape of custom paver casting operations, quality control protocols, and lead time variables that directly impact your project timeline. The state’s extreme climate conditions demand manufacturing standards that exceed typical industry benchmarks, and understanding how custom paver casting facilities operate gives you leverage in specification decisions. Arizona’s hardscape manufacturing plants range from small-batch artisan operations producing bespoke patio stones to high-volume production facilities serving regional distribution networks.

Your material selection process needs to account for manufacturing capabilities specific to Arizona’s climate challenges. Desert heat affects curing protocols, inventory storage conditions, and transportation logistics in ways that coastal or temperate-region fabricators never encounter. Arizona Stone Fabricators who’ve adapted to these conditions demonstrate expertise through specific quality control measures you won’t find in standard industry literature.

Manufacturing Capabilities: Custom Paver Production

Custom paver casting requires you to understand the relationship between design complexity and production feasibility. When you specify bespoke patio stones with intricate surface textures or non-standard dimensions, you’re asking fabricators to modify standard production protocols. Most Arizona Stone Fabricators operate hydraulic press systems ranging from 1,500 to 3,000 PSI capacity, which determines maximum unit size and minimum achievable tolerances.

Your specification documents should address dimensional tolerance expectations explicitly. Standard commercial production typically achieves ±1/8″ tolerance on length and width, with ±1/16″ on thickness. Custom paver casting for architectural applications can tighten these tolerances to ±1/16″ and ±1/32″ respectively, but expect 25-35% cost premium and extended lead times. The trade-off becomes significant when you’re coordinating installations requiring precise dimensional consistency across large format units.

- You need to verify press capacity matches your specified unit dimensions and thickness requirements

- Your custom color specifications require minimum batch sizes, typically 500-1,000 square feet for economic viability

- You should expect 15-20% longer cure times for desert installations compared to temperate climate standards

- Your project timeline must account for Arizona’s summer heat affecting production schedules in non-climate-controlled facilities

Local stone production facilities in Arizona face unique challenges with aggregate sourcing and pigment stability under intense UV exposure. When you work with Arizona Stone Fabricators, you’ll find that successful operations have developed proprietary mix designs addressing thermal expansion coefficients specific to desert temperature cycling. Daily temperature swings of 40-50°F create stress conditions that standard concrete paver formulations can’t accommodate without premature surface deterioration.

Quality Standards: Material Specifications

Arizona Stone Fabricators operating at professional specification grade should demonstrate compliance with ASTM C936 for solid concrete interlocking paving units. Your specifications need to reference this standard explicitly, but you also need to understand its limitations for desert climate applications. The standard establishes minimum 8,000 PSI compressive strength and 5% maximum absorption rate, but doesn’t address thermal cycling performance or UV degradation resistance specific to high-desert environments.

When you evaluate hardscape manufacturing plants for material sourcing, you should request documentation of actual achieved properties, not just minimum standard compliance. Professional fabricators maintain quality control records showing compressive strength test results averaging 9,500-11,000 PSI, providing performance margin for extreme condition exposure. Absorption rates below 4% indicate dense matrix structure that resists efflorescence and freeze-thaw damage in northern Arizona’s elevation zones.

- You must verify compressive strength testing frequency meets minimum requirements of one test per 5,000 square feet production

- Your specifications should require absorption testing on samples from each production batch for custom colors

- You need documentation of abrasion resistance values for high-traffic commercial applications

- Your quality acceptance criteria should include surface texture consistency verification across production lots

The relationship between cement content, aggregate gradation, and water-cement ratio determines long-term performance more reliably than any single test result. Arizona Stone Fabricators who understand this provide mix design documentation showing these parameters. You’re looking for cement content between 650-750 pounds per cubic yard for premium applications, with aggregate gradations following 67% coarse to 33% fine ratios for optimal particle packing density.

Production Lead Times: Scheduling Considerations

Your project schedule needs realistic lead time expectations based on production capacity and order volume. Custom paver casting operations typically quote 4-6 week lead times for standard production runs, but this assumes available manufacturing capacity and raw material inventory. When you specify bespoke patio stones with custom colors or non-catalog dimensions, expect 6-10 week lead times minimum.

Understanding production sequencing helps you coordinate delivery schedules effectively. Most hardscape manufacturing plants batch similar orders together for efficiency, meaning your custom color run might wait for sufficient accumulated orders to justify production setup. If you need guaranteed delivery dates, you’re typically looking at premium scheduling fees of 15-25% to reserve dedicated production time.

Seasonal demand fluctuations significantly impact lead times in Arizona. You’ll encounter the longest delays from January through April when construction activity peaks and Arizona Stone Fabricators operate at maximum capacity. Summer months from June through August often provide shortest lead times as demand decreases, though some facilities reduce production schedules during extreme heat periods affecting non-climate-controlled manufacturing spaces.

- You should place orders minimum 8-10 weeks before required on-site delivery for custom specifications

- Your project timeline needs contingency for potential delays when ordering during peak season

- You must coordinate warehouse delivery schedules with your installation crew availability

- Your procurement strategy should account for minimum order quantities, typically 500-1,000 square feet for custom colors

Aggregate Sourcing: Regional Materials

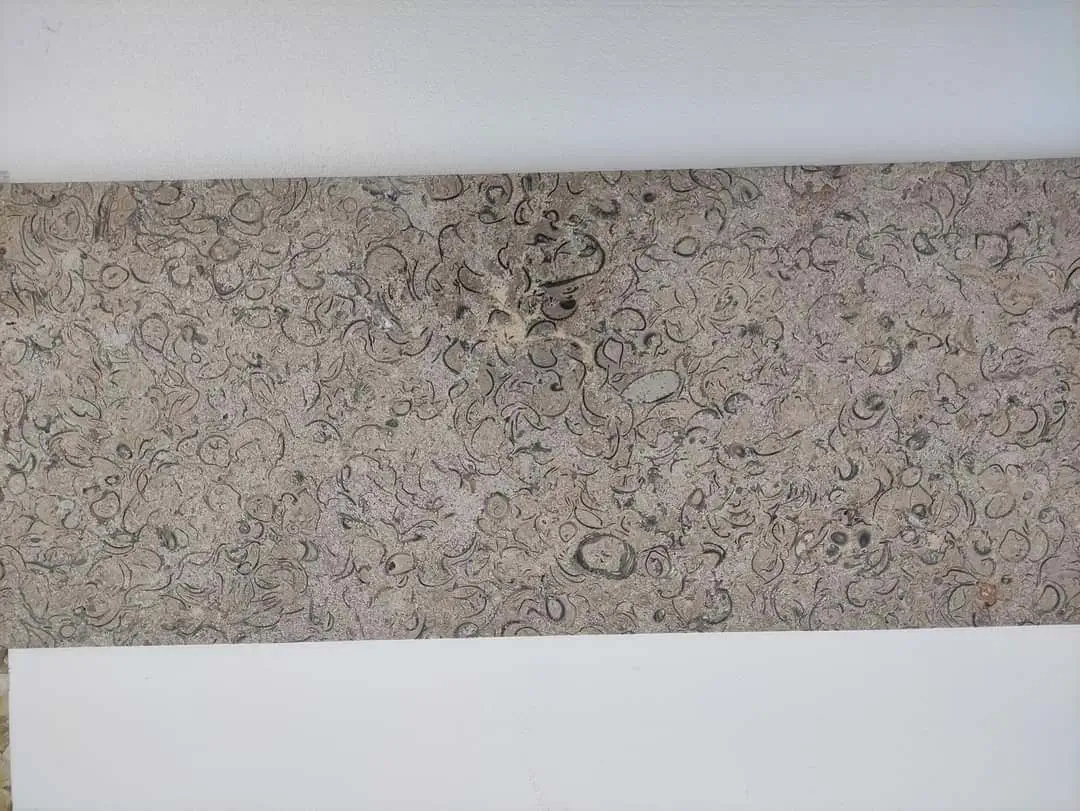

The aggregate sources used by Arizona Stone Fabricators directly affect finished product performance and aesthetic characteristics. Local stone production relies heavily on crushed granite and limestone aggregates quarried within Arizona, which provides natural color palette advantages but requires understanding of regional material properties. Desert-quarried aggregates exhibit lower porosity and higher density compared to sedimentary sources, contributing to improved freeze-thaw resistance.

When you specify material performance requirements, you need to understand how aggregate mineralogy affects thermal properties. Granite-based aggregates demonstrate thermal expansion coefficients around 5.5 × 10⁻⁶ per °F, while limestone aggregates measure slightly lower at 4.8 × 10⁻⁶ per °F. This difference becomes significant in large-format installations where you’re designing expansion joint spacing. For projects with direct solar exposure exceeding 8 hours daily, you should specify joint spacing 15-20% tighter than temperate climate recommendations.

Arizona Stone Fabricators with established aggregate supplier relationships maintain consistent material characteristics across production runs. You want fabricators who source from consistent quarry locations rather than opportunistic purchasing from multiple suppliers. Aggregate consistency directly correlates with color uniformity and predictable performance characteristics across your installation.

Color Consistency: Custom Pigment Formulations

Custom paver casting for architectural applications demands rigorous color control protocols. When you specify bespoke patio stones with integral pigments, you’re introducing the most significant variable in production consistency. Color matching across multiple production batches requires fabricators to maintain precise batching equipment, calibrated scales accurate to 0.1 pound increments, and documented mixing protocols.

Your specification should establish acceptable color variation parameters using industry-recognized measurement systems. Professional Arizona Stone Fabricators utilize spectrophotometry for color verification, providing Delta E values quantifying color difference between samples. For critical architectural applications, specify maximum Delta E of 2.0 between production batches, which represents color difference detectable only under direct comparison. Commercial applications typically accept Delta E values up to 4.0.

- You need to approve color samples from actual production runs, not laboratory-created samples that don’t reflect full-scale manufacturing conditions

- Your project documentation should include approved sample retention for future comparison during production delivery acceptance

- You should specify that all materials for a single project come from coordinated production runs when color consistency is critical

- Your quality acceptance process needs provisions for statistical sampling across delivered pallets, not just top-layer visual inspection

UV-stable pigment selection becomes critical for Arizona applications. Inferior iron oxide pigments demonstrate measurable color shift within 18-24 months under high-desert solar exposure. Professional hardscape manufacturing plants use synthetic iron oxide pigments meeting ASTM C979 specifications for color stability, which cost 40-60% more than standard mineral pigments but eliminate early-life color degradation.

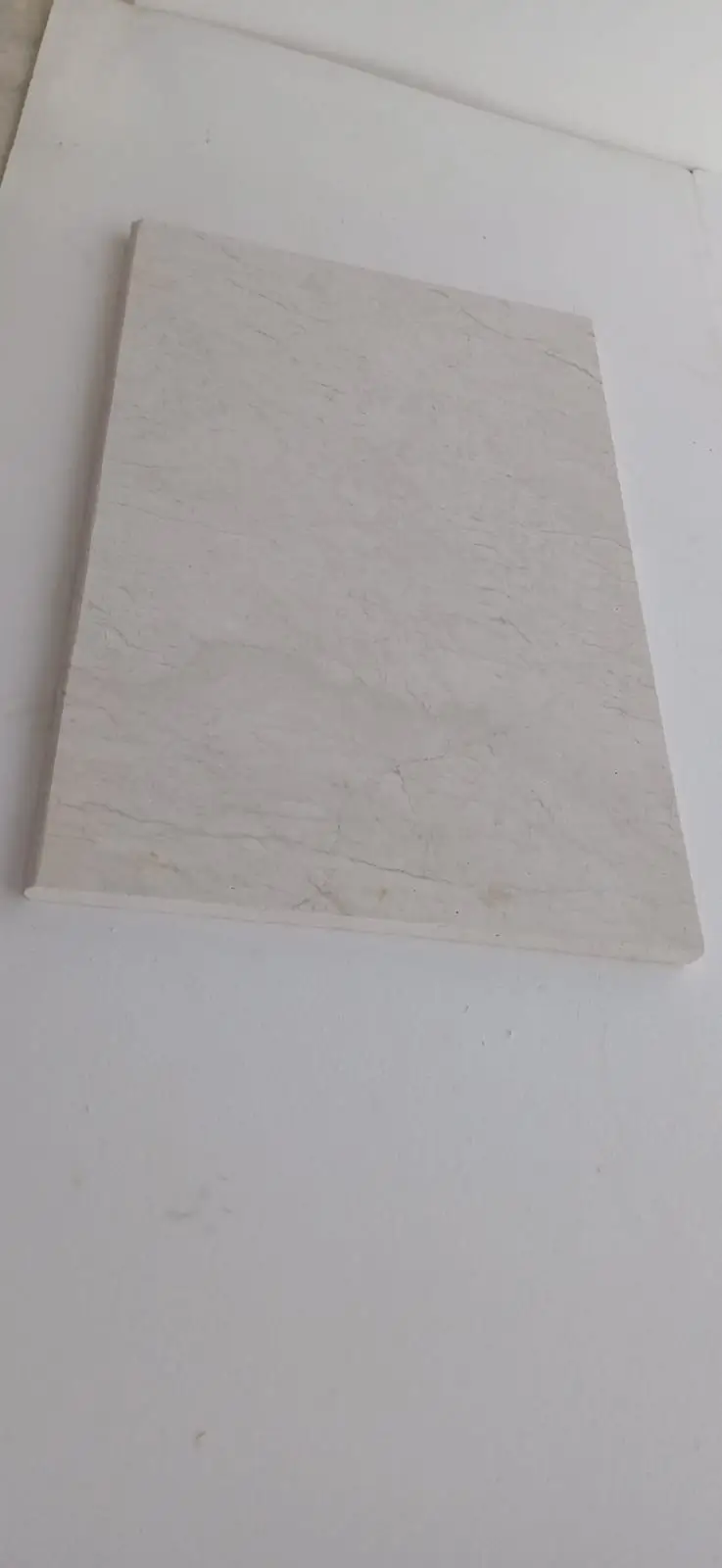

Surface Finish Options: Texture Specifications

The relationship between surface texture and slip resistance requires careful specification for Arizona’s climate conditions. When you specify custom paver casting with specific surface finishes, you’re balancing aesthetic preferences against functional performance requirements. Smooth-troweled finishes provide refined appearance but demonstrate DCOF (Dynamic Coefficient of Friction) values around 0.42-0.48 when wet, below the 0.50 minimum for pool deck applications.

Textured finishes produced through exposed aggregate techniques, broom finishing, or mold-applied patterns achieve DCOF values between 0.55-0.65 when properly executed. You need to specify testing verification for slip resistance when wet, as Arizona Stone Fabricators don’t universally conduct this testing unless explicitly required. For pool decks, water features, or shaded areas prone to moisture retention, specify minimum wet DCOF of 0.60.

Surface texture depth affects long-term maintenance requirements. Deep textures exceeding 1/8″ relief collect debris and organic material requiring pressure washing for appearance maintenance. You’ll find optimal performance with texture depths between 1/16″ and 3/32″, providing adequate slip resistance while facilitating routine cleaning. For projects incorporating our patio stone manufacturing facility materials, texture specifications can be customized to project-specific performance requirements.

Curing Protocols: Desert Climate Adaptation

Arizona’s extreme heat and low humidity create curing challenges that separate professional Arizona Stone Fabricators from marginal operations. Standard concrete curing protocols assume ambient temperatures between 50-80°F and relative humidity above 40%. Desert conditions frequently exceed 105°F with humidity below 15%, creating moisture loss rates that compromise concrete hydration and ultimate strength development.

When you evaluate local stone production facilities, you should inquire about climate-controlled curing environments or alternative moisture retention protocols. Professional operations utilize misting systems, curing compounds, or enclosed curing chambers maintaining temperature below 90°F and humidity above 80% for minimum 7-day initial cure period. Inadequate curing produces surface weakness, reduced abrasion resistance, and increased absorption rates that appear 12-24 months post-installation.

- You need verification that fabricators extend curing time 20-30% beyond standard protocols during summer months

- Your quality specifications should require moisture content testing before palletizing to prevent premature drying

- You should specify that summer production includes curing compound application or continuous moisture maintenance

- Your project acceptance criteria needs provisions rejecting materials showing surface dusting or chalking indicating incomplete cure

Dimensional Accuracy: Installation Implications

The dimensional tolerances achieved by hardscape manufacturing plants directly impact your installation labor costs and finished appearance quality. When you specify custom paver casting with tight tolerances, you’re reducing field adjustment requirements but increasing material costs. Standard production tolerances of ±1/8″ on plan dimensions and ±1/16″ on thickness require experienced installers to accommodate variation through joint width adjustment and selective unit placement.

Your specification should address how dimensional variation compounds across large installations. Tolerance stacking across a 20-foot dimension can accumulate to 3/8″ deviation from planned layout, requiring field cutting or joint width manipulation to maintain pattern alignment. Professional Arizona Stone Fabricators who understand this maintain statistical process control targeting actual dimensional accuracy tighter than specified tolerances, typically achieving ±1/16″ average deviation with ±1/8″ maximum.

Thickness consistency affects setting bed material requirements and installation speed. Variation exceeding ±1/8″ requires installers to adjust base depth on a per-unit basis, increasing labor costs 15-25%. When you’re coordinating large commercial installations, specify maximum thickness variation of ±1/16″ across production lots to facilitate efficient installation procedures.

Thermal Performance: Heat Retention Characteristics

Arizona’s extreme surface temperatures demand consideration of thermal properties in paver selection. Standard concrete pavers in desert applications routinely reach 160-180°F surface temperatures during summer afternoons, creating safety concerns for barefoot traffic and contributing to urban heat island effects. When you work with Arizona Stone Fabricators on custom paver casting, you can influence thermal performance through color selection and aggregate composition.

Light-colored bespoke patio stones with reflective aggregate show surface temperatures 25-35°F cooler than dark colors under identical exposure conditions. The difference becomes critical for pool decks, patios, and pedestrian areas. Your specifications should reference Solar Reflectance Index (SRI) values, targeting minimum SRI of 29 for light colors and avoiding SRI below 18 for dark colors in high-traffic barefoot areas.

- You should specify light reflectance values minimum 0.35 for residential patio applications with barefoot traffic

- Your material selection needs to account for thermal mass effects creating 3-4 hour lag between peak air temperature and peak surface temperature

- You need to coordinate shade structure planning with paver thermal properties for optimal comfort

- Your client education should address realistic temperature expectations for different color choices

Efflorescence Control: Mineral Deposit Prevention

Efflorescence represents one of the most common performance complaints in concrete paver installations, and Arizona’s hard water and alkaline soils exacerbate the issue. When you specify custom paver casting requirements, you should address efflorescence mitigation through mix design parameters. Professional hardscape manufacturing plants reduce efflorescence potential through low water-cement ratios below 0.40, dense aggregate gradations minimizing voids, and controlled calcium hydroxide content.

Your specifications need to recognize that eliminating efflorescence completely is unrealistic, but you can reduce severity and duration. Arizona Stone Fabricators using supplementary cementitious materials like fly ash or slag cement demonstrate 60-70% less efflorescence compared to straight portland cement mixes. The trade-off involves slightly extended curing requirements and 10-15% higher material costs, but eliminates chronic efflorescence problems requiring remediation.

Site drainage design influences efflorescence more than many specifiers recognize. When you design installations on poorly draining bases or without adequate slope for surface water removal, you’re creating conditions that promote efflorescence regardless of material quality. Your installation specifications should mandate minimum 2% slope for surface drainage and require base layer permeability exceeding surface material permeability to prevent subsurface water migration.

Installation Support: Technical Guidance

The level of technical support provided by local stone production facilities varies dramatically across Arizona Stone Fabricators. When you’re specifying materials for complex installations, you need fabricators who provide detailed installation guidelines addressing base preparation, joint specifications, edge restraint requirements, and drainage provisions specific to their products. Premium fabricators offer on-site technical consultation during critical installation phases, ensuring proper execution of specification requirements.

Your project planning should include coordination meetings between fabricator technical representatives, installation contractors, and design professionals. These meetings identify potential conflicts between design intent and practical installation limitations before materials arrive on site. Professional Arizona Stone Fabricators participate in these coordination sessions as standard practice, reviewing access constraints, staging areas, and equipment requirements that affect delivery logistics.

Citadel Stone: Paver Stone Materials in Arizona — How We Would Specify Across Regions

When you consider Citadel Stone’s paver stone materials in Arizona for your commercial or residential project, you’re evaluating premium materials engineered specifically for extreme desert climate performance. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse geographic and climatic regions. This section outlines how you would approach material selection and specification decisions for six representative cities, demonstrating the climate-responsive approach necessary for optimal long-term performance.

Phoenix Valley Heat

In Phoenix, you would encounter extreme heat island conditions requiring careful attention to thermal properties and color selection. Your specifications should address surface temperature management, as summer conditions regularly exceed 115°F ambient temperature. You would specify light-colored materials with minimum Solar Reflectance Index of 29, utilizing reflective aggregates to reduce surface temperatures. The Phoenix urban heat environment demands you consider thermal expansion joint spacing at 15-foot intervals for large-format installations. Your base preparation would need to account for caliche layers common in valley soils, requiring mechanical removal and replacement with engineered base materials. At Citadel Stone, we would recommend extended curing protocols during summer months to ensure proper hydration under low-humidity conditions.

Tucson Specifications

Your Tucson project specifications would address monsoon moisture management combined with extreme heat exposure. You’d encounter expansive clay soils throughout much of the Tucson basin, requiring you to specify geogrid reinforcement in base layers for soil stabilization. Seasonal moisture cycling creates unique challenges where you need drainage provisions handling intense rainfall events following extended dry periods. Your material selection should prioritize low absorption rates below 4% to resist moisture penetration during monsoon season. You would specify minimum compressive strength of 9,500 PSI to accommodate thermal stress cycling. The combination of summer heat and winter freezing at elevation requires you to ensure materials meet both high-temperature performance and freeze-thaw resistance standards.

Scottsdale Resort Quality

Scottsdale’s resort and high-end residential market would require you to specify premium aesthetic standards combined with barefoot-friendly thermal properties. Your specifications should emphasize surface texture achieving DCOF values above 0.60 for pool deck applications while maintaining refined appearance. You’d need to coordinate custom color formulations matching architectural palettes, requiring color consistency documentation and approved sample retention. At Citadel Stone, we maintain warehouse inventory of standard colors to support accelerated project timelines common in luxury residential construction. Your specification would address dimensional accuracy requirements tighter than standard tolerances, typically ±1/16″ to facilitate seamless pattern installations. You should verify that fabrication capabilities accommodate custom edge profiles and specialty shapes for unique design features.

Flagstaff Cold Climate

In Flagstaff, you would shift specification priorities to freeze-thaw durability and traction performance under winter conditions. Your material specifications should require maximum 4% absorption rate and documented freeze-thaw testing per ASTM C1645, demonstrating survival of minimum 50 freeze-thaw cycles without deterioration. You’d encounter annual freeze-thaw events exceeding 100 cycles in northern exposure areas, requiring premium material quality. Your specifications would mandate surface textures providing wet and icy condition traction, targeting minimum DCOF of 0.65. At Citadel Stone, we would recommend mix designs incorporating air entrainment and supplementary cementitious materials improving freeze-thaw resistance. You should specify that summer installation timing allows proper curing before first winter freeze events.

Sedona Aesthetic Integration

Your Sedona specifications would emphasize natural color integration with red rock surroundings and tourism-focused aesthetic standards. You’d coordinate custom pigment formulations achieving earth-tone palettes compatible with strict design review requirements. Your specifications should address UV-stable pigments meeting ASTM C979 to prevent color degradation under intense high-elevation solar exposure. You would need to account for site access challenges common in hillside developments, coordinating truck delivery logistics and material staging. The combination of winter freezing and summer heat requires you to specify materials meeting comprehensive performance standards. Your installation specifications would address slope stabilization and drainage requirements on hillside terrain.

Yuma Extreme Conditions

In Yuma, you would confront the most extreme heat conditions in Arizona, requiring maximum attention to thermal performance and long-term stability. Your specifications should mandate lightest available colors with maximum solar reflectance properties to maintain barefoot accessibility. You’d encounter soil conditions with high salinity requiring you to specify enhanced efflorescence resistance through supplementary cementitious materials. Your material selection should prioritize dimensional stability under extreme thermal cycling exceeding 50°F daily temperature swings. You would specify extended warranty provisions addressing accelerated weathering conditions unique to desert border environments. At Citadel Stone, we would recommend semi-annual sealing maintenance programs to preserve appearance under these demanding exposure conditions.

Logistics: Delivery Coordination

Understanding delivery logistics from hardscape manufacturing plants helps you coordinate efficient material flow to job sites. Arizona Stone Fabricators typically palletize materials on standard 48″ × 48″ pallets weighing 2,000-3,500 pounds depending on unit thickness and size. Your site planning needs to accommodate truck access for vehicles ranging from 26-foot straight trucks to 53-foot tractor-trailers, with weight considerations for fully loaded deliveries approaching 40,000 pounds.

Delivery scheduling requires coordination between fabricator production completion, truck availability, and site readiness. You should verify warehouse stock availability before finalizing project timelines, as stock materials ship within 3-5 business days while custom orders follow production lead times. Your site logistics plan needs to address material staging areas, protection from weather exposure, and forklift access for palletized delivery unloading.

- You must confirm site access dimensions accommodate delivery truck turning radius and overhead clearance

- Your delivery scheduling should account for driver hour-of-service regulations limiting delivery windows

- You need designated material storage areas protecting products from direct ground contact and moisture exposure

- Your receiving procedures should include immediate quality inspection and documentation of delivery condition

Cost Variables: Pricing Considerations

Pricing for custom paver casting varies based on numerous factors you need to understand for accurate budget development. Standard production materials from Arizona Stone Fabricators typically range from $3.50 to $6.50 per square foot at the manufacturing facility. Custom colors add $0.75-$1.50 per square foot, while non-standard dimensions or specialty finishes increase costs $1.25-$2.75 per square foot depending on complexity.

Your budget planning should account for minimum order quantities affecting unit pricing. Orders below 500 square feet typically carry 25-40% price premiums due to setup costs and production inefficiencies. Volume discounts become available at thresholds of 2,000, 5,000, and 10,000 square feet, with potential savings of 12-18% at highest volumes. Delivery costs add $150-$400 depending on distance from fabricator to job site and total order weight.

Seasonal pricing variations occur with demand fluctuations, though less dramatically than in northern climates. You’ll find best pricing during summer months when construction activity slows, with potential savings of 8-12% compared to peak spring season pricing. When you coordinate procurement timing strategically, you can capture these savings without compromising project schedules.

Final Specifications

Your professional specification process for Arizona paving projects requires comprehensive understanding of how Arizona Stone Fabricators operate within the state’s unique climate and market conditions. You need to evaluate manufacturing capabilities, quality control protocols, and technical support infrastructure to identify fabricators capable of meeting project performance requirements. The relationship between custom paver casting complexity, lead time expectations, and cost considerations demands realistic planning and clear communication throughout procurement and installation phases.

When you develop specifications for bespoke patio stones or standard production materials, you should address the complete performance envelope including compressive strength, absorption characteristics, dimensional accuracy, slip resistance, and thermal properties. Your procurement strategy must account for seasonal demand fluctuations, minimum order quantities, and delivery logistics to maintain project timeline integrity. Quality acceptance procedures should include documented testing verification, dimensional compliance checking, and color consistency evaluation across delivered materials. For comprehensive support throughout the specification and procurement process, review Direct factory pricing programs for Arizona paving contractors before you finalize project documents. Exotic materials available through Citadel Stone’s imported patio slab suppliers in Arizona.