When you’re planning outdoor living spaces in Arizona’s demanding climate, you need paving solutions that deliver both structural performance and installation efficiency. Interlocking Paver Systems AZ offer mechanical stability through precision-engineered edge profiles that distribute loads without requiring mortar beds or rigid substructures. You’ll find these modular landscape blocks provide significant advantages over traditional poured concrete or mortared stone, particularly when you’re working with expansive clay soils or sites with limited truck access for heavy equipment.

The fundamental advantage you gain with Interlocking Paver Systems AZ comes from their ability to flex with substrate movement while maintaining surface integrity. Arizona’s seasonal moisture fluctuations create soil expansion coefficients that can reach 8-12% volume change in clay-heavy regions. When you install rigid concrete slabs in these conditions, you’re looking at crack propagation within 18-36 months. Interlocking systems absorb this movement through individual unit articulation and properly maintained joint sand, which acts as both a load transfer medium and a drainage pathway.

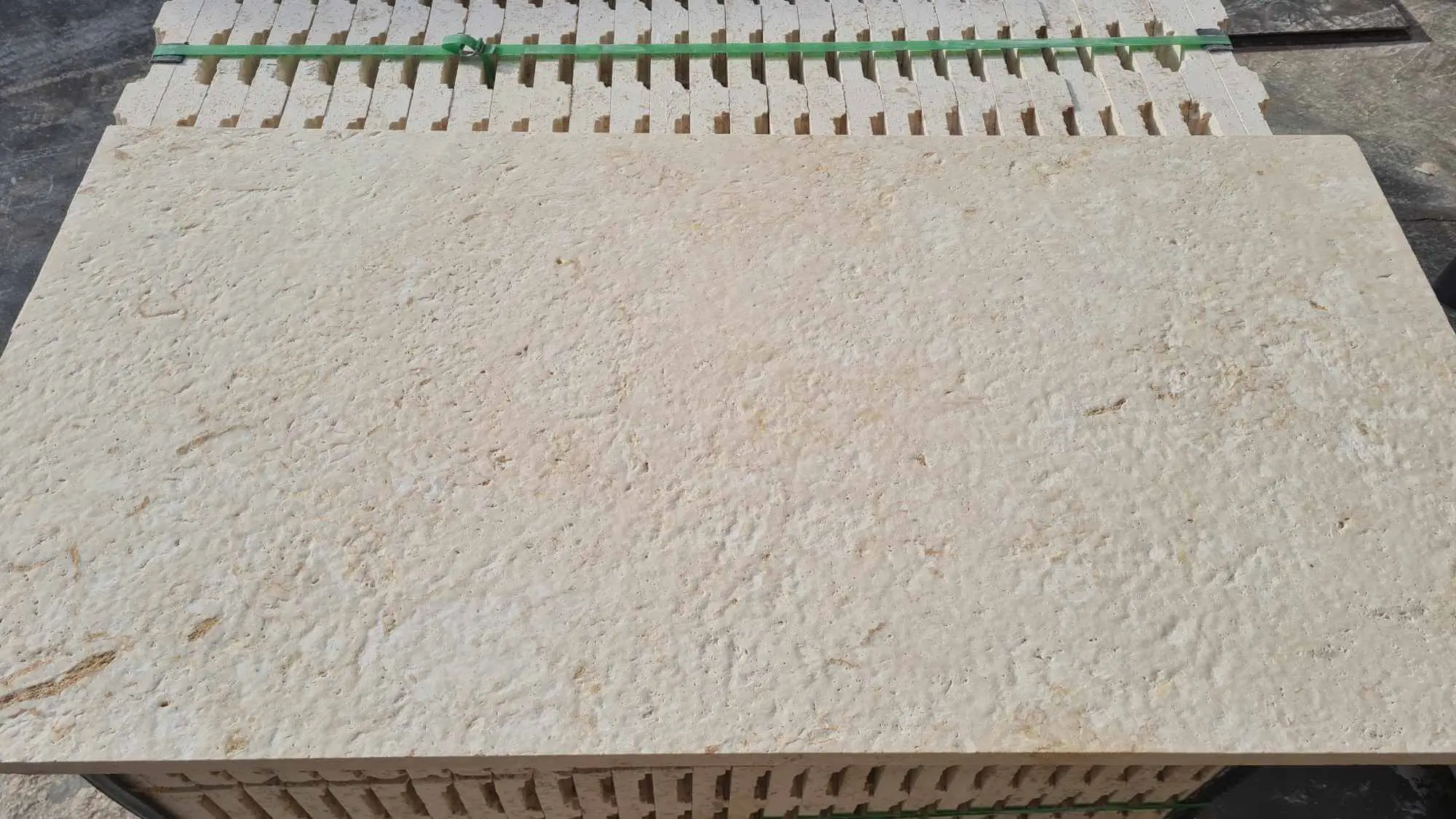

Your material selection process should account for thermal performance characteristics that standard product literature often oversimplifies. Surface temperatures on dark pavers in Phoenix can exceed 165°F during July afternoons, while lighter-colored units typically peak at 135-145°F. This 20-30°F differential affects everything from pedestrian comfort to long-term color stability. The thermal mass behavior of these systems creates a 3-4 hour lag between peak air temperature and peak surface temperature, which you can leverage for installation scheduling and outdoor space usability patterns.

Engineered Edge Geometry and Load Distribution

The mechanical performance of Interlocking Paver Systems AZ depends entirely on edge profile geometry and how these profiles interact under load. You’re not simply placing adjacent units next to each other—you’re creating a stressed-skin system where horizontal interlock prevents vertical displacement. The most effective profiles feature offset engagement depths of 5-8mm, which allow for manufacturing tolerances while maintaining positive mechanical connection.

When you evaluate locking concrete pavers for commercial applications, you need to understand the difference between geometric interlock and friction-based stability. Geometric interlock creates physical impedance to movement through shaped edges—typically castellated, rabbeted, or curved profiles. These shapes generate resistance to both horizontal creep and vertical displacement under dynamic loading. Friction-based systems rely primarily on unit weight and joint sand to prevent movement, which proves inadequate in high-traffic areas or on slopes exceeding 3%.

- You should specify edge profiles with minimum 6mm engagement depth for vehicular applications

- Your joint spacing must remain between 2-4mm to maintain interlock while allowing drainage

- You’ll need transition details at fixed structures to accommodate 8-12mm horizontal movement

- Your specification should require minimum 60mm thickness for parking areas with regular truck traffic

The load distribution mechanism you create depends on maintaining continuous contact across edge profiles. When joint sand migrates out of the system—which happens at rates of 15-25% annually without proper edge restraint—you lose the load transfer medium that prevents point loading. This leads to individual unit rocking, accelerated edge spalling, and progressive system failure. You can prevent this through properly installed edge restraint systems and biennial joint sand replenishment that maintains 90-95% joint fill capacity.

Base Preparation Protocols for Arizona Soils

Your installation success with modular landscape blocks starts 18-24 inches below finished surface elevation, where you address native soil characteristics that determine long-term performance. Arizona soils range from expansive clays with plasticity indices above 30 to granular desert soils with almost zero cohesion. You can’t apply generic base preparation specifications across this range—each soil type requires specific stabilization and drainage approaches.

When you encounter clay soils with liquid limits above 40, you’re dealing with materials that will expand 6-10% in volume when saturated. Your base design must either remove these soils entirely to depths of 24-36 inches, or stabilize them through chemical treatment with hydrated lime at 3-5% by weight. The stabilization approach works when you can achieve thorough mixing and proper moisture conditioning, but it extends your installation timeline by 7-10 days for curing. Removal and replacement with engineered fill provides more predictable outcomes but increases material costs by $4-7 per square foot.

The aggregate base layers you install above stabilized subgrade serve three functions: load distribution, drainage, and vertical stability. You need minimum 6 inches of compacted Class 2 aggregate base (3/4-inch minus) for pedestrian applications, increasing to 8-12 inches for vehicular loads. Each lift should not exceed 4 inches before compaction, and you must achieve 95% modified Proctor density at optimum moisture content. Under-compaction by even 2-3% creates long-term settlement that manifests as surface depressions within 24-36 months.

- You should verify subgrade bearing capacity exceeds 10% CBR before placing base aggregate

- Your compaction testing must occur every 2,500 square feet minimum on commercial projects

- You’ll need to maintain 2% minimum cross-slope in base layers for positive drainage

- Your edge restraint must bear on the same compacted base as paving units, not on uncompacted native soil

Joint Sand Specifications and Long-Term Performance

The joint sand you select for easy install patio bricks determines whether your installation maintains integrity for 15+ years or requires major intervention within 5-7 years. You’re not just filling voids between units—you’re installing the load transfer medium that prevents individual unit rotation and distributes forces across the entire system. Standard masonry sand fails in this application because particle size distribution doesn’t provide mechanical interlock and angular particles fracture under repeated loading.

Joint sand specifications for Interlocking Paver Systems AZ must address particle angularity, gradation, and durability. You need angular to sub-angular particles that create mechanical friction, with gradation between #30 and #50 sieve sizes. Rounded particles from water-washed sources compact to lower density and migrate out of joints 40-60% faster than angular particles. The material must also resist degradation—soft sandstone-derived sands break down under traffic, creating fines that wash out and leave voids.

Your installation protocol must account for the difference between initial joint fill and long-term stable fill. When you first sweep sand into joints and compact the surface, you’re achieving 70-80% of ultimate density. The remaining consolidation occurs over 6-12 months as traffic and environmental exposure complete the compaction process. You should plan for supplemental sand application at 6 months post-installation, adding material to restore joints to 90-95% fill capacity. This second application typically requires 40-50% of the initial sand volume.

Thermal Cycling and Dimensional Stability Requirements

Arizona’s extreme temperature ranges create thermal cycling conditions that affect Interlocking Paver Systems AZ through both material expansion and substrate movement. You’ll see daily temperature swings of 40-50°F during spring and fall, with seasonal ranges exceeding 100°F between July peaks and January overnight lows. These cycles drive dimensional changes that your installation must accommodate through proper joint spacing and edge restraint design.

The coefficient of thermal expansion for concrete-based permeable paving blocks ranges from 4.5 to 5.5 × 10⁻⁶ per °F, depending on aggregate mineralogy and cement content. Over a 100°F seasonal temperature range, a 20-foot paver section expands approximately 0.14 inches. This seems minimal until you consider that expansion occurs in all directions simultaneously and accumulates across large installations. When you’re working with 50-foot patio dimensions, you’re managing 0.35 inches of thermal movement that must be absorbed through joints or accommodated at perimeter edges.

- You need expansion joints every 20-25 feet in installations exceeding 1,000 square feet

- Your perimeter edge restraint must allow 10-15mm movement without creating compressive loading

- You should avoid rigid connections to building foundations that prevent thermal movement

- Your joint width specification must account for both thermal expansion and manufacturing tolerances

The interaction between thermal expansion and moisture-driven substrate movement creates complex loading conditions that determine whether installations remain stable or develop progressive failure patterns. When thermal expansion occurs during hot dry periods while clay subgrades are contracting, the system experiences reduced bearing support coinciding with maximum dimensional stress. You can mitigate this through proper base preparation that isolates pavers from expansive soils, but you can’t eliminate the thermal component that affects the paving units themselves.

Permeable System Design for Water Management

When you’re specifying permeable paving blocks for Arizona applications, you’re addressing stormwater management requirements while dealing with infiltration rates that vary by three orders of magnitude depending on soil type. Permeable systems provide 0.5-1.0 inches per hour infiltration in ideal conditions, but this assumes proper installation and appropriate subgrade permeability. You need to verify that native soil infiltration rates support permeable design—if subgrade permeability is less than 0.2 inches per hour, you’re creating a bathtub that undermines the entire system.

The aggregate base layers in permeable installations serve as temporary water storage in addition to their structural function. You design these layers with clean, angular stone—typically #57 or #8—that provides 35-40% void space for water retention. A 12-inch permeable base layer stores approximately 0.33 feet of water per square foot of surface area, which handles most Arizona storm events that deliver 0.5-1.5 inches of precipitation. The stored water then infiltrates into subgrade over 24-48 hours following the storm event.

Your specification must address the conflict between structural compaction requirements and permeability maintenance. Standard compaction protocols that achieve 95% density reduce void space and permeability by 30-40%. For permeable systems, you need to specify compaction to 88-92% density using vibratory plate compactors without excessive passes. This requires more careful installation oversight and typically adds 15-20% to base preparation costs compared to conventional installations.

Edge Restraint System Engineering and Installation

The edge restraint system you install determines whether locking concrete pavers maintain their designed configuration or creep outward over time, losing interlock and creating trip hazards at perimeters. You’re creating a tensile element that resists horizontal forces generated by traffic loading, thermal expansion, and base settlement. Inadequate edge restraint is responsible for 70-80% of premature paver system failures in commercial applications.

Concrete edge restraints provide the most reliable long-term performance when you install them properly. You need minimum 4-inch width by 8-inch depth concrete curbs that bear on the same compacted base as paving units. The curb face must contact paver edges continuously, without gaps exceeding 1/4 inch. Any gap larger than this allows individual units to rotate outward, progressively losing interlock starting from the perimeter. You should specify #4 rebar at 24-inch centers in concrete edge restraints for installations exceeding 500 square feet.

Plastic edge restraint systems offer faster installation but require proper spike density and depth to develop adequate holding force. You need commercial-grade restraints with minimum 1/4-inch thickness and 4-inch vertical leg dimension. Spike spacing must not exceed 12 inches on center, with each spike penetrating minimum 8 inches into compacted base aggregate. When you’re working with modular landscape blocks in areas subject to vehicular traffic, plastic restraints prove inadequate—you should specify concrete or steel edge systems for these applications.

Color Stability and UV Resistance in Desert Environments

Your material selection for Interlocking Paver Systems AZ must account for UV exposure intensity that exceeds 8,000 Langley units annually in southern Arizona locations. This extreme exposure drives photochemical degradation in pigments and binder systems, causing color fade that becomes visually apparent within 3-5 years in poorly formulated products. You need to understand the difference between through-color units and surface-pigmented products, because this determines whether fade creates acceptable patina or unacceptable blotchiness.

Through-color concrete pavers incorporate pigments throughout the entire unit thickness, typically using iron oxide pigments at 3-6% by weight. When surface wear or weathering occurs, the color remains consistent because you’re exposing identical material composition. Surface fade on through-color units tends toward uniform lightening—the entire installation shifts gradually to a lighter shade without creating contrasting areas of wear versus non-wear.

Surface-pigmented easy install patio bricks use a separate wear layer approximately 5-10mm thick that contains higher pigment concentrations. This approach provides more intense initial colors and better economics on decorative patterns. However, when differential wear occurs—which it will in traffic paths versus protected areas—you see color variation that highlights usage patterns. In high-end residential applications where appearance uniformity matters, you should specify through-color products despite their 15-25% cost premium.

- You should request weathering test data showing maximum 5-Delta E color change over 1,000 hours QUV exposure

- Your specification must address whether color matching will be required for future additions or repairs

- You’ll need to educate clients that some color evolution is normal and often desirable as patina development

- Your material selection should consider whether surrounding hardscape colors will also evolve over time

Installation Logistics and Site Access Planning

When you’re coordinating delivery and installation of permeable paving blocks, site access constraints often determine whether your project proceeds efficiently or encounters costly delays. A typical residential patio installation requires 15-25 tons of pavers plus 20-35 tons of base aggregate, delivered on trucks that need 12-foot width clearance and adequate overhead clearance for side-dump operations. You should verify truck access during project planning, not when the first delivery arrives on site.

Warehouse lead times for specialty profiles and colors typically range from 3-6 weeks during peak construction season. Standard products in neutral colors—grays, tans, and buff tones—often ship within 5-10 business days from regional distribution centers. When you’re specifying premium colors or custom patterns, you need to account for these longer lead times in your project schedule. Rush orders are sometimes possible at 15-25% cost premiums, but availability isn’t guaranteed during March-May peak season.

Your installation crew productivity depends heavily on material staging and site organization. Professional crews installing Interlocking Paver Systems AZ achieve 150-250 square feet per day per installer on straightforward layouts with minimal cuts. Complex patterns with alternating colors or extensive border details reduce productivity to 100-150 square feet per installer per day. You should plan material staging areas within 50 feet of installation zones to minimize labor time spent on material handling rather than actual installation work.

For guidance on complementary paving materials and design integration, see our wholesale patio paving for comprehensive technical specifications and availability information.

Slope Stabilization Techniques for Elevated Applications

When you’re installing locking concrete pavers on slopes exceeding 3%, standard installation methods prove inadequate—you need enhanced stabilization techniques that prevent downhill creep. Gravity forces on sloped installations create continuous stress that compounds over time, particularly during thermal expansion when units are already under dimensional stress. You’ll see movement rates of 1-3mm per year on 5% slopes without proper stabilization, accumulating to 10-30mm over a decade.

Your primary stabilization approach should utilize grid reinforcement systems embedded in the base aggregate layer. These high-density polyethylene grids provide tensile reinforcement that resists downhill soil movement while allowing water drainage. You install them directly on compacted subgrade before placing base aggregate, with minimum 12-inch overlap at seams and positive anchorage at the upslope edge. The grid becomes encapsulated in base aggregate, creating a composite material with tensile strength 8-12 times higher than unreinforced aggregate alone.

- You need geogrid reinforcement on any slope exceeding 4% in vehicular applications

- Your installation must include upslope key-in trenches minimum 18 inches deep to anchor the grid

- You should specify biaxial geogrids with minimum 1,500 lb/ft tensile strength at 5% strain

- Your edge restraint at the downslope edge must be upgraded to concrete curb regardless of application type

Additional stabilization comes from adhesive that bonds pavers together at edges, converting the flexible system into a semi-rigid mat. You apply polyurethane-based adhesive along edge profiles during installation, creating mechanical bonds that cure within 24-48 hours. This technique works well for slopes between 5-8% but changes the system behavior—you lose the flexibility that accommodates substrate movement, so you must be confident in your base preparation quality.

Common Specification Errors and Field Corrections

The most frequent error you’ll encounter in Interlocking Paver Systems AZ specifications is inadequate attention to base preparation requirements relative to soil conditions. Generic specifications that call for “6 inches compacted aggregate base” fail to address whether existing soils require removal, stabilization, or can support pavers directly. You need soil-specific base design that accounts for bearing capacity, expansion potential, and drainage characteristics. When you inherit projects with inadequate base specifications, field corrections become expensive—you’re looking at $8-15 per square foot for remedial base work on failed installations.

Joint sand specification errors typically involve either under-specifying performance requirements or specifying inappropriate materials. When specifications simply call for “clean masonry sand,” you’ll receive whatever the supplier considers meets that description—often material with excessive fines content or rounded particle shape that migrates out of joints rapidly. Your specification must define particle size distribution (passing #16 sieve, retained on #50 sieve), maximum fines content (less than 3% passing #200 sieve), and particle angularity requirements. These specifics ensure you receive material that performs adequately for the intended application.

Edge restraint specifications often fail to address bearing requirements or connection details to existing structures. When you specify edge restraint without requiring it to bear on compacted base, installers sometimes place it on uncompacted native soil where it settles differentially from the paver field. You need explicit requirements that edge restraint bears on the same structural base as paving units and extends to the same depth. Connection details at building foundations, steps, and other fixed elements require engineering that most generic specifications don’t provide.

Maintenance Protocols and Service Life Extension

Your maintenance program for easy install patio bricks determines whether installations deliver 25+ year service life or require major intervention at 10-15 years. The most critical maintenance task is joint sand replenishment, which should occur on a biennial schedule for the first 6 years post-installation, then shift to every 3-4 years once the system reaches equilibrium. You’re adding material to compensate for gradual migration and degradation, maintaining the 90-95% fill capacity that supports proper load distribution.

Surface cleaning requirements depend on exposure conditions and aesthetic expectations. In desert environments with minimal organic debris, annual cleaning with water and mechanical agitation suffices for most applications. When you’re dealing with installations near trees or in areas with significant dust accumulation, you may need quarterly attention. High-pressure washing works effectively but requires care—pressure exceeding 3,000 PSI or nozzles held too close to the surface can erode joint sand and damage surface finishes. You should specify maximum 2,500 PSI at 12-inch minimum distance with fan spray nozzles.

- You need annual inspection of edge restraint integrity, repairing any separation before units begin migrating

- Your maintenance program should include drainage verification, ensuring water doesn’t pond on the surface

- You’ll want to address any lippage or rocking units immediately, before they create progressive failure patterns

- Your long-term budget should include complete joint sand replacement every 15-20 years as material gradually degrades

Sealer application remains controversial in the paver industry. Sealers enhance color depth and can reduce staining, but they require reapplication every 3-5 years and alter surface characteristics. When you apply sealers to Interlocking Paver Systems AZ, you’re creating maintenance obligations that many property owners fail to fulfill—partially worn sealer looks worse than no sealer at all. For commercial applications where maintenance budgets support regular resealing, products that enhance appearance while reducing maintenance make sense. For residential applications without dedicated maintenance programs, you should avoid sealers entirely.

Citadel Stone Paver Stones Bulk in Arizona: Regional Specification Guidance

When you consider Citadel Stone’s paver stones bulk in Arizona for your project, you’re evaluating engineered products designed specifically for southwestern climate extremes. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse geographic and climatic regions. This section outlines how you would approach material selection and specification decisions for six representative cities, illustrating the climate-specific considerations that affect performance in each location.

Arizona’s climate zones range from low desert with extreme heat and minimal precipitation to high elevation regions with significant freeze-thaw cycling and winter moisture. You need different material specifications and installation protocols for each zone. The guidance provided here represents recommended approaches for typical projects in each city, helping you understand how regional conditions would influence your specification decisions.

Phoenix Heat Performance

In Phoenix applications, you would need to prioritize thermal performance and dimensional stability under extreme heat conditions. Summer temperatures regularly exceed 115°F, creating surface temperatures on dark pavers that can reach 165-170°F. Your material selection should emphasize lighter colors that reflect 55-65% of solar radiation, keeping surface temperatures 25-35°F cooler than dark alternatives. You would specify through-color units with iron oxide pigments that resist UV degradation over the expected 25-30 year service life. Joint sand selection becomes critical—you need angular particles that maintain interlock despite thermal cycling through 90-100°F daily temperature ranges during summer months. Base preparation would address caliche layers common in Phoenix soils, typically requiring removal to 24-inch depths and replacement with engineered fill.

Tucson Elevation Considerations

For Tucson projects at 2,400-foot elevation, you would account for slightly more moderate temperatures than Phoenix but higher precipitation during monsoon season. Your drainage design must handle intense rainfall events that deliver 1-2 inches in 60-90 minutes during July-August storms. You would specify permeable paving blocks with minimum 0.5 inches per hour infiltration rates, assuming subgrade soils support infiltration-based stormwater management. The specification would address greater freeze-thaw exposure than Phoenix—Tucson averages 15-25 freeze events annually at this elevation. You need materials with maximum 5% absorption to prevent freeze-thaw damage, verified through ASTM C1645 testing protocols. Your installation would include enhanced edge restraint to manage the erosive forces from channelized runoff during monsoon events.

Scottsdale Premium Applications

When you specify Interlocking Paver Systems AZ for Scottsdale’s high-end residential market, aesthetic considerations typically equal or exceed performance requirements. You would select premium color blends and complex patterns that create visual interest while maintaining the thermal and structural performance needed for desert conditions. Your specification might include multiple unit sizes in a modular pattern, requiring detailed layout drawings and enhanced installer qualifications. Material selection would emphasize color stability testing data showing maximum 5-Delta E color shift over accelerated weathering equivalent to 10 years natural exposure. You would address pool deck applications common in this market, specifying slip-resistant surfaces with DCOF ratings minimum 0.50 when wet. Edge details at pool coping and planters require waterproofing integration that protects underlying structures from moisture intrusion.

Flagstaff Freeze-Thaw Requirements

In Flagstaff at 7,000-foot elevation, you would shift focus to freeze-thaw durability as the primary performance criterion. This location experiences 150+ freeze-thaw cycles annually with significant snow load during winter months. Your material specification must require maximum 3% absorption and minimum 8,000 PSI compressive strength to withstand these conditions. You would verify freeze-thaw durability through ASTM C1645 testing showing maximum 1% weight loss and no visible damage after 50 cycles. Base preparation becomes more complex—you need minimum 12-inch aggregate base depth with 4-6 inches below the frost depth, which reaches 24-30 inches in this climate zone. Your joint sand specification would address deicing salt exposure, requiring non-reactive aggregates that won’t deteriorate from calcium chloride or magnesium chloride contact during snow removal operations.

Sedona Aesthetic Integration

For Sedona projects, you would balance technical performance with aesthetic integration into the distinctive red rock landscape. Material colors typically emphasize earth tones—terracotta, buff, and brown blends—that harmonize with natural surroundings. Your specification would need to address moderate freeze-thaw exposure at 4,500-foot elevation, with 40-60 annual freeze events. You would select modular landscape blocks with absorption maximum 4% and compressive strength minimum 6,000 PSI. The installation would account for sloped sites common in Sedona topography, requiring geogrid reinforcement on any slope exceeding 4%. Your drainage design must protect red soil from erosion while managing intense but infrequent precipitation events. Edge restraint specifications would address integration with existing natural stone walls and landscape features prevalent in Sedona architectural styles.

Yuma Extreme Heat

In Yuma applications, you would design for the most extreme heat conditions in Arizona—summer temperatures regularly exceed 118°F with minimal nighttime cooling. Your primary concern becomes pedestrian comfort and material dimensional stability under sustained thermal stress. You would specify light-colored locking concrete pavers with minimum 70% solar reflectance, potentially including white or cream tones that maintain surface temperatures below 140°F even during peak heat. The specification must address thermal expansion across large installations—you need expansion joints every 20 feet in any dimension exceeding 40 feet. Your base preparation would account for extremely low natural moisture content in Yuma soils, requiring moisture conditioning to achieve proper compaction. You would verify that warehouse inventory includes adequate stock of specified materials before committing to project timelines, as specialty light colors may require 4-6 week lead times from manufacturing facilities.

Performance Validation and Testing Protocols

When you’re specifying Interlocking Paver Systems AZ for projects requiring performance verification, you need to understand which test methods provide meaningful data versus which generate numbers that don’t predict field performance. Compressive strength testing per ASTM C140 is standard industry practice, but you should recognize that values above 8,000 PSI show minimal correlation with actual service life in pedestrian applications. Flexural strength per ASTM C1645 provides better performance prediction because it measures tensile characteristics that determine crack resistance.

Absorption testing per ASTM C140 directly predicts freeze-thaw durability and stain resistance. You should specify maximum absorption values based on climate exposure: 3% for severe freeze-thaw regions with 100+ annual cycles, 5% for moderate freeze-thaw with 25-75 cycles, and 7% for no-freeze locations where absorption affects primarily stain resistance. Lower absorption improves performance but increases cost—you’re looking at 10-15% price premiums for units with absorption below 3% compared to standard products at 5-6%.

Slip resistance testing using DCOF measurement per ANSI A326.3 provides data you can use for specification compliance. However, you need to understand that testing occurs on clean, controlled surfaces that don’t represent field conditions. Published DCOF values of 0.50-0.55 translate to real-world wet performance around 0.42-0.48 after surface weathering and organic film development. You should specify minimum 0.55 DCOF for pool decks and other wet areas, understanding this provides approximately 0.45-0.50 actual wet performance after 12-18 months of service.

Next-Generation System Innovations

Recent developments in Interlocking Paver Systems AZ technology focus on enhanced permeability, improved thermal performance, and simplified installation. You’re seeing products with engineered void spaces that increase infiltration rates to 100+ inches per hour—far exceeding conventional permeable systems at 0.5-1.0 inches per hour. These high-flow systems work well in Arizona where intense monsoon rainfall needs rapid drainage, but they require careful subgrade evaluation to ensure infiltrated water doesn’t create subsurface saturation problems.

Thermal modification technologies now include phase-change materials embedded in concrete matrices that absorb heat during temperature rise and release it during cooling. These systems can reduce peak surface temperatures by 15-20°F compared to conventional products. However, you need to understand the economics—these specialized products typically cost 40-60% more than standard units, which makes them viable primarily for high-value commercial projects where reduced heat island effect justifies the investment.

Installation efficiency improvements include self-spacing nibs and alignment features molded into unit edges. When you’re working with easy install patio bricks featuring these innovations, you can achieve 20-25% faster installation compared to products requiring manual spacing. The challenge comes in repair scenarios—if you need to replace individual units, the alignment features can make removal and reinstallation more difficult than traditional systems. You should weigh installation efficiency against long-term maintenance accessibility when selecting products with these features.

Your specification strategy should balance proven conventional technology against emerging innovations. For projects where budget allows experimentation and where enhanced performance justifies premium costs, newer technologies make sense. For value-focused projects requiring predictable outcomes and straightforward maintenance, conventional modular landscape blocks remain the appropriate choice. For additional design guidance on authentic southwestern aesthetics, review Natural stone pavers for authentic Spanish colonial courtyard designs before you finalize your material selections and installation specifications. Interlocking systems come from Citadel Stone, the most engineered patio block suppliers in Arizona.