When you design desert front yard rock designs in Arizona, you’re working with one of the most demanding climates in North America. Your material choices need to withstand 115°F surface temperatures, intense UV exposure exceeding 6,500 hours annually, and thermal cycling that ranges 60-70 degrees between night and day. You’ll find that successful installations balance three critical factors: reflectivity to manage heat island effects, porosity for monsoon drainage, and dimensional stability across extreme temperature swings.

The challenge you face isn’t just selecting attractive materials—it’s specifying stone that maintains structural integrity and appearance for 20+ years under relentless solar radiation. Your front yard serves as the primary architectural statement, and material failure becomes immediately visible to everyone passing by. You need to understand how different stone types respond to Arizona’s unique combination of heat, UV exposure, and sudden moisture events during monsoon season.

Thermal Performance Requirements

Surface temperature management drives material selection for desert front yard rock designs in Arizona more than any other factor. When you specify stone for full-sun exposure, you’re dealing with surface temperatures that can reach 165°F on dark granite and 140°F on lighter limestone. This isn’t just about comfort—these temperatures affect everything from structural movement to surrounding plant survival.

You should prioritize materials with albedo values above 0.40 for desert applications. Light-colored flagstone, decomposed granite, and cream limestone reflect 60-70% of solar radiation, reducing surface temperatures by 15-25 degrees compared to dark basalt or black river rock. Your clients will notice the difference immediately when walking barefoot from house to mailbox becomes tolerable rather than painful.

- You need to account for thermal expansion coefficients between 5.1-5.8 × 10⁻⁶ per °F for most natural stone

- Your joint spacing should accommodate 3/16″ to 1/4″ movement per 20 linear feet in full sun

- You’ll want materials with thermal mass properties that delay peak surface temperature by 3-4 hours after air temperature peaks

- Your specification must address how substrate temperature affects root zone conditions for adjacent plantings

The interaction between stone color and warehouse availability often creates specification challenges. Light-colored materials that perform best thermally don’t always stock in quantities sufficient for large residential installations. You should verify truck delivery schedules can meet your project timeline before committing to specific materials, especially during peak construction season when warehouse inventory turns over quickly.

Flagstone Applications and Precision Details

Flagstone entryways for Arizona homes require different installation protocols than you’d use in temperate climates. The material’s natural cleft surface provides inherent slip resistance (DCOF 0.48-0.54 when dry), but you need to address how monsoon moisture affects traction. Wet flagstone can drop to 0.38-0.42 coefficient, which approaches marginal safety thresholds for sloped walkways.

When you lay out flagstone entryways for Arizona homes, your base preparation determines long-term performance more than stone quality itself. You’ll need 4-6 inches of compacted aggregate base with particle gradation that allows rapid drainage while preventing settlement. The common mistake is using standard 3/4″ minus base—you want angular crushed stone with 10-15% fines maximum to maintain interlock without clogging pore space.

Your flagstone selection should account for thickness variation that typically runs ±3/8″ on natural cleft material. This variance affects setting bed depth and labor hours significantly. You can specify gauged flagstone at premium cost, or you’ll need to allocate 15-20% more installation time for shimming and leveling. For curb appeal landscape rock Arizona projects, the visual impact of consistent plane justifies the additional labor investment.

Joint treatment separates professional installations from amateur work in desert front yard rock designs in Arizona. You need polymeric sand rated for temperature extremes—standard formulations break down when substrate temperatures exceed 145°F. The polymers degrade under UV exposure, and you’ll see joint failure within 18-24 months if you use products designed for moderate climates. Specify materials tested to ASTM D6913 with UV stabilizers rated for 7,500+ hours exposure.

River Rock Size and Drainage Engineering

River rock functions as both decorative element and drainage medium in low-maintenance front yard gravel AZ installations, but you need to specify size ranges that serve both purposes effectively. The 1-3 inch range works for most residential applications, providing visual texture while allowing water infiltration rates of 40-60 inches per hour. Smaller materials migrate and require edge restraint, while larger cobbles create visual heaviness inappropriate for front yard scale.

You’ll encounter a common specification error: selecting river rock purely for appearance without considering how it interacts with underlying landscape fabric. When you place 2-3 inch river rock directly on standard woven geotextile, foot traffic drives stones through the fabric within one season. You need non-woven geotextile with puncture strength exceeding 500 lbs (ASTM D6241) or accept that you’ll be repairing torn fabric and dealing with soil intrusion.

- Your specification should call for 3-4 inch depth minimum to prevent soil exposure as material settles

- You need to account for 15-20% material loss in first year as smaller pieces migrate to底部

- Your edge restraint must extend 2 inches above finish grade to contain material during monsoon runoff events

- You should specify rounded river rock rather than crushed stone where foot traffic occurs—crushed edges are uncomfortable and sharp

Color stability varies dramatically across river rock sources, and this matters for curb appeal landscape rock Arizona applications where appearance drives property value. Wet-set river rock shows true color, but in Arizona’s arid climate, you’re looking at dry stone 95% of the year. Reds fade to pink, grays bleach to tan, and blacks develop white efflorescence—all within 2-3 years. You want materials from igneous sources with Mohs hardness above 6.5 for better color retention.

Concrete Paver vs Natural Stone Performance

The paver versus natural stone decision for desert front yard rock designs in Arizona comes down to three factors: thermal behavior, maintenance requirements, and long-term appearance. Concrete pavers offer dimensional consistency and lower initial cost, but they absorb and retain heat differently than natural stone. You’ll see surface temperatures 8-12 degrees higher on concrete compared to limestone of similar color due to differences in thermal conductivity and evaporative properties.

When you evaluate popular front yard rock colors Arizona homeowners request, you’re balancing aesthetic preference against thermal performance. Tan and beige dominate requests, but within that range, you have materials performing at opposite extremes. Buff-colored concrete pavers might hit 155°F while cream travertine reaches only 138°F under identical conditions. Your clients notice this difference at the front door every summer afternoon.

Natural stone provides inherent color variation that concrete manufacturers try to replicate but never quite achieve. This variation either enhances or detracts from design intent depending on your project goals. For formal entries requiring pattern precision, concrete pavers deliver consistency. For organic desert landscapes where you’re creating visual flow between hardscape and natural surroundings, flagstone’s variation reinforces the design concept. You need to match material character to design intent rather than defaulting to lowest cost.

Maintenance requirements diverge significantly between material types. Concrete pavers require sealing every 2-3 years in Arizona’s UV environment to prevent surface degradation and color fading. Natural stone needs sealing for stain resistance but doesn’t experience the same UV breakdown of surface binders. You’ll find that our landscape slab stone selection includes materials that maintain appearance with minimal intervention. Your specification should account for 20-year lifecycle costs, not just installation pricing.

Material Color and Heat Island Mitigation

Popular front yard rock colors Arizona residents request don’t always align with materials that perform best thermally. You face the challenge of educating clients about how color choice affects not just appearance but actual temperature around their home’s entry. Dark charcoal and black accents that look stunning in design renderings create localized hot spots that radiate heat for 3-4 hours after sunset.

Solar reflectance index (SRI) provides quantifiable comparison across materials, but you need to translate technical data into practical impact. A material with SRI of 29 (typical dark granite) versus SRI of 78 (light limestone) represents 25-30 degree surface temperature difference at 2 PM in July. That’s the difference between landscape plants surviving or dying within 18 inches of hardscape edges.

- You should specify materials with SRI above 60 for south and west exposures in full sun

- Your design can incorporate darker accents in shaded areas or where thermal mass benefits evening comfort

- You need to account for how surrounding hardscape affects microclimate around entry plantings

- Your color selections should consider how dust accumulation affects reflectivity over time—light surfaces show dirt but maintain better thermal performance

Color permanence separates professional-grade materials from commodity stone in desert front yard rock designs in Arizona. UV exposure at Arizona elevations exceeds 7,000 hours annually in many locations, and materials respond differently. Sedimentary stone like sandstone and limestone maintain color better than some metamorphic stone that can experience mineral oxidation. You’ll see iron-bearing stone develop rust stains, and copper-bearing materials turn green—effects that either enhance or detract depending on design expectations.

Monsoon Drainage and Erosion Control

Monsoon season transforms low-maintenance front yard gravel AZ installations from static decorative elements into active drainage systems. You need to design for storm events that deliver 1-2 inches of rain in 30-minute periods, creating runoff velocities that move loose stone and expose underlying fabric. Your material sizing, edge details, and substrate preparation all determine whether installations survive monsoon season intact.

When you specify decomposed granite or small gravel (1/4 to 3/4 inch), you’re working with materials that become mobile at water velocities above 2 feet per second. In sloped front yards, this threshold gets exceeded easily during peak monsoon events. You need one of three solutions: increase particle size to 1-2 inch range, incorporate stabilized DG products with polymer binders, or install subsurface drainage that reduces surface flow velocity.

Base preparation determines whether you’re fighting erosion issues for the next 20 years or achieving stable installation. You want base compaction between 92-95% maximum density—over-compaction creates impermeable surface that channels water rather than allowing infiltration. Your compaction specification needs to account for soil type, with clay-heavy soils requiring different protocols than sandy desert soils common in lower elevation areas.

- You should design positive drainage away from building foundations with minimum 2% slope

- Your specification must address how hardscape drainage integrates with landscape planting areas to prevent washout

- You need edge restraint rated for lateral pressure from both material weight and water flow forces

- Your installation should include transition zones where velocity reduces before water reaches adjacent properties

Subsurface drainage often gets overlooked in desert climates because extended dry periods make the need less obvious. Then monsoon hits, and you’re dealing with saturated base layers that compromise stone stability. You should incorporate perforated drain lines in low areas and along building perimeters, connecting to appropriate discharge points. This adds cost upfront but eliminates expensive repairs later.

Decomposed Granite Stabilization Methods

Decomposed granite serves dual roles in desert front yard rock designs in Arizona—functional pathways and visual contrast to planted areas. But you need to address the material’s tendency to migrate, track indoors, and develop surface crust that sheds water rather than allowing infiltration. Stabilization method selection affects performance, maintenance, and long-term appearance significantly.

Natural DG without stabilizers provides the most permeable surface and most authentic appearance, but requires ongoing maintenance. You’ll need to rake and replenish material annually, losing 10-15% depth per year to compaction and migration. Edge erosion becomes pronounced along planting beds and lawn interfaces. For low-maintenance front yard gravel AZ applications, this maintenance requirement conflicts with client expectations.

Polymer-stabilized DG reduces maintenance dramatically but changes material behavior in ways you need to understand. The installation process requires precise moisture content during compaction—too dry and polymers don’t activate, too wet and you get uneven binding. You have about 4-hour working window after moisture addition, which affects labor scheduling and means you can’t leave partial areas for next-day completion.

Resin-stabilized systems provide the firmest surface and best erosion resistance, approaching the performance of pervious concrete. But you’re dealing with a permanent installation that can’t be easily modified. Tree root growth, utility access, and design changes all become more complicated. Your specification needs to match stabilization level to expected permanence—formal entries with established design justify resin systems, while evolving landscape areas work better with lighter stabilization or natural DG.

Edge Details and Material Containment

Edge restraint failure causes more callbacks on flagstone entryways for Arizona homes than any other installation defect. You’ll see pavers settling, gravel migrating, and joints opening when edge details don’t account for thermal expansion, traffic loads, and monsoon erosion forces. The aluminum landscape edging common in moderate climates doesn’t provide sufficient rigidity for Arizona conditions.

When you detail edges for desert front yard rock designs in Arizona, you need restraint systems that handle 140-160°F material temperatures without deforming. Aluminum edging loses rigidity at elevated temperatures, allowing gradual outward creep that opens joints and drops edges below finish grade. Steel edging provides better rigidity but requires powder coating or stainless alloys to prevent rust staining on adjacent stone.

- Your edge specification should call for commercial-grade restraint with minimum 1/8 inch wall thickness

- You need to anchor edging every 12-18 inches with spikes reaching minimum 8 inches into undisturbed base

- Your installation must set edging top 1/4 inch above finish grade to contain material as settling occurs

- You should detail how edging transitions at curves, maintaining continuous restraint without gaps

Concrete mow strips and borders provide the most permanent edge solution and create clean visual lines for curb appeal landscape rock Arizona installations. But you’re adding significant cost and creating future inflexibility. Your concrete edges need proper reinforcement and control joints every 4-6 feet to prevent cracking from thermal movement and soil settlement. Thickness should be minimum 4 inches with width proportional to visual scale—3-4 inch wide borders look skimpy on typical residential installations.

The transition between different materials requires careful detailing to prevent the visible gap that develops as materials settle at different rates. When you’re connecting flagstone to river rock or pavers to decomposed granite, you need transition zones that accommodate 1/4 to 3/8 inch differential settlement. This might mean slightly overlapping materials during installation or incorporating metal transition strips that hide gaps while allowing independent movement.

Premium Landscape Stone Delivery in Arizona — Citadel Stone Regional Specifications

When you consider Citadel Stone’s landscape stone delivery in Arizona for your front yard installation, you’re evaluating materials specifically selected for extreme desert performance. At Citadel Stone, we provide technical guidance for diverse applications across Arizona’s varied climate zones, from low desert heat to high elevation freeze-thaw conditions. This section outlines how you would approach material specification and installation planning for six representative cities, addressing the unique environmental challenges each location presents.

Phoenix Heat Performance

In Phoenix, you’ll encounter the most extreme heat conditions in Arizona, with 115°F+ air temperatures and surface temperatures reaching 165°F on dark materials. Your specification must prioritize high-albedo stone with solar reflectance above 0.65 to maintain manageable surface temperatures. You would select cream limestone or light granite that keeps entry areas tolerable during peak afternoon hours. The urban heat island effect in Phoenix amplifies thermal stress by 8-12 degrees compared to surrounding desert, so your material choices directly impact livability around home entries. You need to verify that warehouse inventory includes sufficient quantities of light-colored flagstone before committing to project schedules, as demand peaks during fall installation season.

Tucson Monsoon Drainage

Tucson’s intense monsoon season would drive your drainage engineering more than in other Arizona cities, with storm events frequently exceeding 2 inches per hour. You should specify base preparation that allows 50+ inches per hour infiltration while maintaining surface stability during high-velocity runoff. Your material selection would favor 2-3 inch river rock in drainage swales and stabilized decomposed granite in flat areas where erosion risk is lower. The city’s slightly higher elevation moderates peak temperatures by 3-5 degrees compared to Phoenix, giving you more flexibility with mid-tone stone colors. You would incorporate subsurface drainage along all building perimeters to handle the concentrated runoff that occurs during July and August storm patterns.

Scottsdale Luxury Standards

Scottsdale installations would demand the highest aesthetic standards, where material color consistency and installation precision directly affect property values in luxury home markets. You should specify premium-grade flagstone with minimal color variation and thickness tolerance within 1/4 inch. Your joint treatment would use UV-stabilized polymeric sand in colors custom-matched to stone selection, maintaining clean lines that reinforce formal landscape architecture. The competitive luxury market means your material choices need to differentiate the property while maintaining broad appeal—earth tones in the buff to light brown range prove most successful. You would detail truck access carefully, as many Scottsdale neighborhoods have restrictive delivery hours and street access limitations that affect project logistics.

Flagstaff Freeze Protection

In Flagstaff’s high-elevation climate, you would shift focus from heat management to freeze-thaw durability, with 120+ annual freeze cycles requiring materials with porosity below 5% and proven cold-climate performance. Your specification should call for dense granite or quartzite rather than the limestone that performs well in lower elevations. You need materials tested to ASTM C1645 for freeze-thaw resistance, with absorption rates below 0.4% to prevent ice formation within the stone matrix. The 7,000-foot elevation creates 40-degree temperature swings that stress materials differently than low-desert cycling. You would detail proper drainage to prevent water accumulation in joints where freeze expansion can displace pavers and flagstone.

Sedona Color Integration

Sedona’s iconic red rock landscape would inform every material selection decision, with successful installations integrating rather than competing with the natural surroundings. You should specify warm-toned flagstone in rust, tan, and coral ranges that echo the Schnebly Hill Formation visible throughout the area. Your design would avoid stark white or gray stone that creates visual conflict with the environment. The moderate elevation (4,500 feet) requires you to address both summer heat and occasional winter freezing, calling for materials with proven all-season performance. Local design review boards often have specific requirements about material compatibility with natural landscape character, so you would verify approval requirements before finalizing specifications.

Yuma Extreme Conditions

Yuma represents the most extreme heat and UV exposure in Arizona, with summer temperatures consistently 3-5 degrees above Phoenix and solar radiation intensity amplified by lower elevation and southern latitude. You would specify only the lightest-colored materials available, prioritizing thermal performance over all other factors. Your installation timeline should avoid May through September entirely when surface temperatures make material handling difficult and setting materials cure unpredictably. The minimal precipitation (3 inches annually) means you can reduce drainage infrastructure compared to other locations, but dust control becomes critical during installation. You need materials with surface texture that doesn’t show dust accumulation as prominently, since cleaning frequency will be higher than in areas receiving occasional rain.

Plant Material Compatibility and Root Zone Temperature

The interaction between desert front yard rock designs in Arizona and adjacent plant materials determines landscape survival more than irrigation schedules or soil amendments. When you place stone within 12 inches of plant root zones, you’re creating thermal conditions that can raise soil temperature 15-20 degrees compared to mulched areas. Your plant selection needs to account for these modified conditions or you’ll be replacing dead shrubs within two seasons.

Heat-reflective stone provides human comfort benefits but can create hostile conditions for plants on south and west exposures. Light-colored gravel reflects solar radiation upward onto lower leaf surfaces that lack protective wax layers, causing photosynthetic stress even on desert-adapted species. You should maintain 18-24 inch buffer zones between high-albedo stone and plant canopies, filling the gap with organic mulch that moderates temperature and provides transition.

- Your planting plan should specify species with heat tolerance ratings appropriate for modified microclimate

- You need to increase irrigation frequency by 15-20% for plants adjacent to extensive hardscape compared to landscape-only areas

- Your design should position heat-sensitive accent plants away from stone surfaces that create radiant heat exposure

- You should incorporate vertical elements like walls or large rocks that provide afternoon shade for plant root zones

Root intrusion into hardscape installations causes progressive damage that becomes expensive to repair. Mesquite, palo verde, and other desert trees send surface roots 30-40 feet from trunk, and these roots lift pavers and displace edging as they expand. You need root barriers extending 24 inches deep along tree-side edges of hardscape, or you should maintain minimum 8-foot separation between trees and paved areas. Your clients often resist this separation during installation, but you’ll avoid callbacks years later when roots create trip hazards and drainage problems.

Installation Mistakes That Compromise Performance

The most common specification error you’ll encounter in desert front yard rock designs in Arizona is inadequate base preparation to save cost. Reducing base depth from 6 inches to 4 inches cuts material cost by 30% but guarantees settlement issues within 3-5 years. You can’t shortcut base preparation in expansive clay soils or areas with poor drainage—the cost savings disappear when you’re repairing settled pavers and re-leveling flagstone.

Joint sand selection represents another frequent mistake where specifications default to standard masonry sand rather than polymeric products designed for extreme conditions. Regular sand washes out during monsoon events, allows weed growth, and provides no resistance to ant colonization. You’ll spend more on annual maintenance than the initial cost premium for quality polymeric sand. Your specification should call for products tested to 150°F+ with UV stabilizers rated for 7,500-hour exposure.

Sealer selection and application often gets treated as afterthought rather than integral performance factor. You need penetrating sealers that don’t create surface film—film-forming sealers trap moisture, leading to spalling and efflorescence as subsurface water tries to escape. Your specification should require breathable sealers that allow vapor transmission while blocking liquid water and oil penetration. Application timing matters critically; sealing before joints are fully stabilized and initial efflorescence has occurred locks in problems rather than preventing them.

- You should specify minimum 28-day cure period before sealing new installations to allow initial settling and efflorescence

- Your application requirements need to address surface temperature limits—sealer performance degrades when applied to stone above 90°F

- You need maintenance schedules that call for resealing every 2-3 years in high UV environments

- Your specifications must address how sealer interacts with joint sand to prevent bonding that creates maintenance problems

Ignoring thermal expansion in layout design creates long-term joint problems as materials cycle through 60-70 degree daily temperature ranges. You need expansion joints every 15-20 feet in large paved areas, with joint material that compresses and rebounds through thousands of cycles. The common error is treating expansion joints as unnecessary in pedestrian applications—thermal movement occurs regardless of traffic type, and restrained movement causes cracking and displacement.

Long-Term Maintenance Planning

Successful low-maintenance front yard gravel AZ installations still require regular attention to maintain performance and appearance—”low maintenance” doesn’t mean “no maintenance.” You should set realistic client expectations about the care schedule needed to preserve their investment. Annual maintenance typically includes joint sand replenishment, sealer reapplication every 2-3 years, edge restoration, and weed control in gravel areas.

Joint sand maintenance becomes critical in year 2-3 when initial overfilling has washed away and joints settle to stable depth. You need to replenish polymeric sand to maintain 92-95% fill capacity—underfilled joints allow lateral paver movement and accelerate wear. The process requires removing the top 1/2 inch of existing sand, cleaning joints thoroughly, and installing new polymeric sand with proper moisture activation. Your maintenance specifications should detail this process rather than leaving it to homeowner interpretation.

Efflorescence appears on many installations during year 1-2 as soluble salts migrate to the surface. This is normal mineral behavior, not installation defect, but clients perceive it as material failure unless you’ve explained the process upfront. You can minimize efflorescence through proper base material selection, avoiding cement-stabilized bases under natural stone, and ensuring adequate drainage prevents water accumulation. Treatment involves dry brushing or mild acid washing depending on severity—your maintenance guide should provide specific protocols.

Organic growth in joints and on stone surfaces varies by microclimate but becomes noticeable within 2-3 years in areas receiving regular irrigation overspray. Algae appears as green or black discoloration, while moss develops in continuously moist shaded areas. You should specify periodic treatment with appropriate cleaners rather than high-pressure washing that damages joint sand and can etch softer stone. Your maintenance schedule needs to address seasonal cleaning that prevents buildup rather than intensive intervention after growth becomes established.

Budget Factors and Material Procurement

Material cost for desert front yard rock designs in Arizona varies more by availability than by quality grade. You’ll find that locally-quarried flagstone costs 30-40% less than imported materials, but local options might not provide the color range your design requires. Your specification needs to balance aesthetic goals against budget realities, and you should provide material alternatives at different price points rather than single-source specifications that limit contractor bidding.

Truck delivery logistics affect total project cost significantly in Arizona’s spread-out metropolitan areas. When you’re sourcing materials from warehouses in Phoenix for Tucson installations, freight can add 15-20% to material cost. You need to verify regional warehouse inventory before specifying materials that require long-distance transport. For large projects, direct quarry shipments might provide better pricing than local supplier markup, but minimum order quantities typically exceed residential project needs.

Installation labor costs vary by material complexity and site conditions more than by geographic location. Flagstone installation runs $12-18 per square foot for standard patterns, increasing to $20-25 for intricate custom layouts. Your design complexity directly affects budget—simple running bond patterns cost half what you’ll pay for random ashlar or curved pattern work. You should detail pattern specifications clearly so contractors can provide accurate labor pricing rather than padding bids to cover uncertainty.

- You need to account for 10-15% material overage for natural stone to accommodate breakage and pattern cutting

- Your budget should include edge restraint, base materials, and joint products that often get overlooked in preliminary estimates

- You should plan for delivery timing and warehousing if materials arrive before site is ready for installation

- Your project schedule needs to accommodate 4-6 week lead times for specialty materials not stocked locally

Sealer, joint sand, and maintenance supplies add 8-12% to material costs but prevent expensive repairs later. You’re better off specifying quality products upfront than dealing with callbacks for failed joints and stained surfaces. Your material budget should itemize these components separately so clients understand they’re essential performance elements, not optional upgrades.

Final Specifications

Your professional specification process for desert front yard rock designs in Arizona requires you to integrate thermal performance, structural engineering, aesthetic goals, and maintenance realities into cohesive installation documents. You need to address how materials respond to extreme heat, UV exposure, and monsoon dynamics while creating the curb appeal that drives property value. The difference between installations that perform for 20+ years and those requiring expensive repairs within 5 years comes down to specification details that account for Arizona’s unique climate challenges.

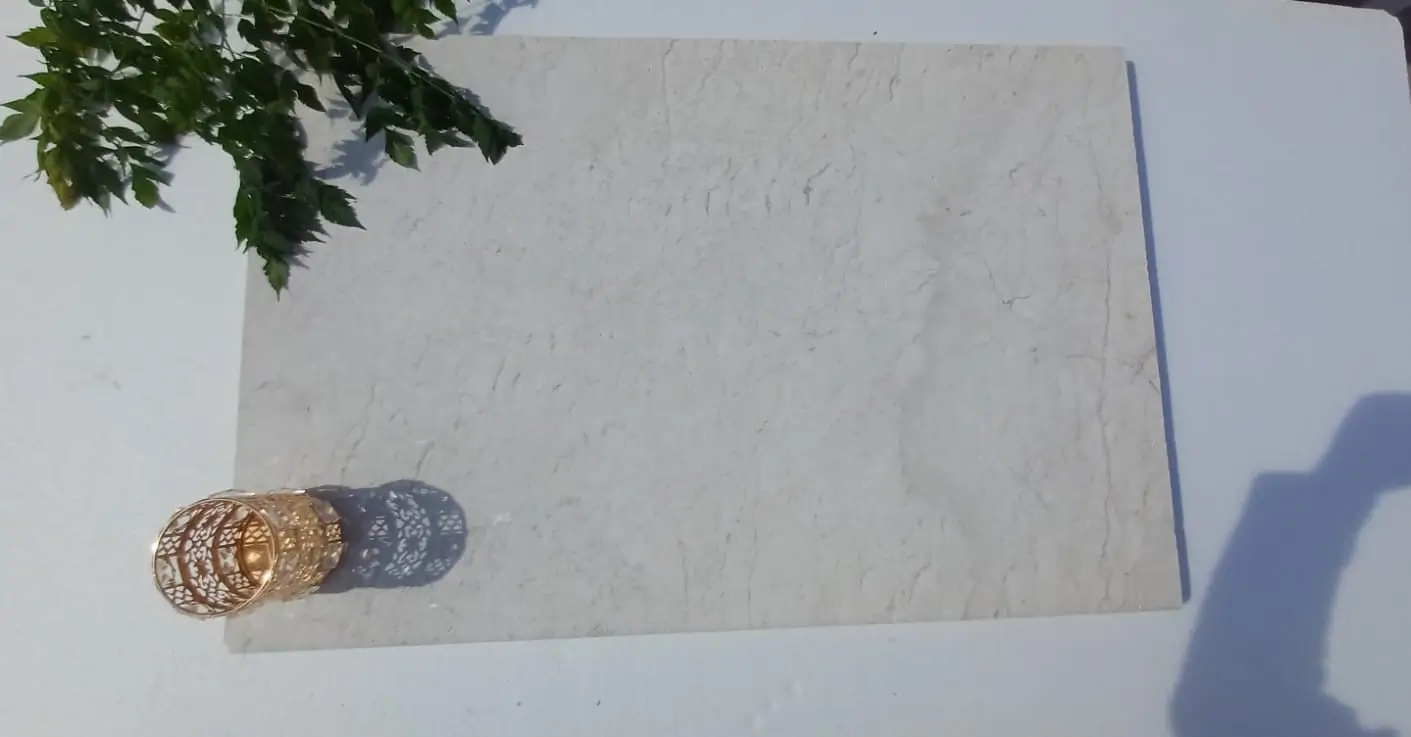

When you develop material selections, you should verify that performance data reflects testing under conditions matching your project location. Laboratory values for porosity, slip resistance, and thermal properties don’t always predict field performance when materials face 115°F temperatures and 7,000-hour UV exposure. You want materials with proven track records in similar applications, and you should request reference projects you can inspect for real-world aging characteristics. For additional material performance insights specific to premium installations, review Madison Gold granite applications in Arizona desert landscaping projects before you finalize your project specifications. Bright contemporary gardens feature Citadel Stone’s clean landscape stone white in Arizona marble and limestone.