When you evaluate material sourcing transparency stone manufacturing Arizona for your next commercial or high-end residential project, you’re navigating a landscape where quarry origins and ethical practices matter as much as compressive strength and slip resistance. You need to verify that your stone manufacturer can trace material back to specific extraction sites, document handling protocols, and demonstrate environmental compliance throughout the supply chain. This level of transparency isn’t just about corporate responsibility — it directly affects your project timeline, material consistency, and long-term performance guarantees.

Material sourcing transparency stone manufacturing Arizona requires understanding three critical elements: quarry location documentation, extraction method verification, and chain-of-custody protocols. You should demand that your stone manufacturing in Arizona quarry tracking systems provide GPS coordinates, geological reports, and extraction permits for every load. In practice, this means your supplier can tell you exactly which quarry face produced your material, when it was extracted, and how it was processed. This traceability becomes essential when you need to source matching material for future phases or repairs — without documented origins, you’re gambling on color and grain consistency.

The distinction between transparent and opaque sourcing practices shows up in three ways you’ll encounter during specification. First, transparent stone manufacturing and supply in Arizona ethical sourcing operations provide detailed geological reports that include mineral composition, porosity ranges, and performance testing tied to specific quarry locations. Second, you’ll receive batch documentation that tracks material from extraction through fabrication, allowing you to verify consistency across delivery schedules. Third, you gain access to environmental compliance records that demonstrate responsible extraction practices, which increasingly matters for LEED certification and ESG reporting requirements your clients demand.

Quarry Documentation Requirements

You need to understand what constitutes adequate quarry documentation before you commit to a supplier. Legitimate documentation includes surveyed extraction site coordinates, active mining permits from state and federal agencies, and geological assessment reports that characterize the stone deposit. Your specification should require suppliers to provide quarry site identification numbers, extraction dates, and processing facility locations. This level of detail protects you when color variation issues arise or when you need to source additional material months or years after initial installation.

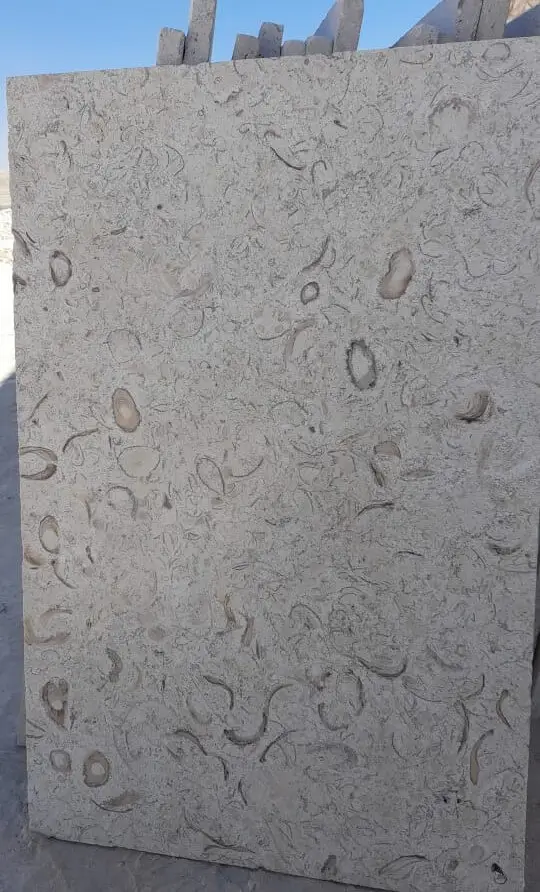

Professional stone manufacturing and supply company Arizona origins tracking involves more than simple paperwork. You should verify that your supplier maintains photographic documentation of quarry faces, extraction equipment, and processing facilities. When you review these records, look for consistency between stated quarry locations and visible geological features. Desert quarries in Arizona exhibit distinct stratification patterns, mineral inclusions, and weathering characteristics that knowledgeable specifiers can use to authenticate sourcing claims. Suppliers who hesitate to provide this documentation typically source from multiple locations opportunistically, which compromises material consistency.

The verification process you’ll implement depends on project scale and budget constraints. For projects exceeding 10,000 square feet, you should consider third-party verification of quarry documentation. Independent geologists can review extraction permits, visit quarry sites, and validate that material characteristics match stated origins. This investment typically costs $2,500-$5,000 but protects you against specification failures that could cost ten times that amount in remediation. Your documentation review should confirm that quarry operations comply with Surface Mining Control and Reclamation Act requirements and maintain current bonding for site restoration.

Extraction Method Verification

When you evaluate extraction methods, you’re assessing factors that directly affect material performance and consistency. Quarry operations use three primary extraction techniques: diamond wire sawing, controlled blasting, and hydraulic splitting. Each method produces distinct characteristics in the finished stone that affect your installation success. Diamond wire cutting creates minimal micro-fracturing and produces the most consistent dimensional tolerances, typically ±1/8 inch. Controlled blasting introduces stress fractures that may not become visible until after installation, particularly in freeze-thaw climates. Hydraulic splitting falls between these extremes, offering cost efficiency with acceptable consistency for most commercial applications.

You’ll find that stone manufacturing companies in Arizona transparency regarding extraction methods reveals critical information about long-term performance. Material extracted through diamond wire sawing exhibits 15-20% higher flexural strength compared to blasted material from the same formation. This difference matters when you specify thin-format materials or applications with point loads. Your supplier should document extraction method for each production run, allowing you to correlate installation performance with quarry practices. Transparent operators maintain extraction logs that record technique, equipment settings, and quality control observations tied to specific batch numbers.

- Diamond wire sawing produces cleanest cuts with minimal subsurface damage and consistent dimensional accuracy

- Controlled blasting introduces micro-fractures extending 6-12 inches beyond blast holes, affecting structural integrity

- Hydraulic splitting offers middle-ground solution with acceptable consistency for most commercial applications

- Extraction method directly correlates with material yield rates and finished product pricing

- Transparent documentation allows you to specify extraction requirements in procurement contracts

The relationship between extraction method and your project requirements becomes critical in high-performance applications. When you specify material for vehicular traffic areas, thermal cycling environments, or structural applications, extraction technique affects service life projections. Your supplier should provide compressive strength testing, flexural strength data, and absorption rates tied to specific extraction methods. Professional specifications reference these performance metrics and require batch-specific documentation demonstrating compliance. For guidance on comprehensive sourcing evaluation, see Citadel Stone’s manufacturing division for detailed technical protocols.

Chain of Custody Protocols

Your material tracking requirements should mirror the rigor of pharmaceutical supply chains when project specifications demand consistency and traceability. Chain of custody documentation follows stone from quarry extraction through processing, warehousing, and delivery to your job site. Each transfer point requires documentation that includes material identification numbers, quantity verification, quality inspection results, and handler signatures. This protocol ensures that material you inspect during sample approval matches material delivered three months later for installation. Without documented custody chains, you risk receiving material from different quarries, production runs, or even different stone types that merely approximate your specifications.

Material sourcing transparency stone manufacturing Arizona operations that implement proper custody protocols use barcode or RFID tracking systems linking physical material to digital records. When you receive delivery, your field team scans identification tags that provide access to complete material history: extraction date, quarry coordinates, processing facility, inspection results, and warehouse storage duration. This technology-enabled transparency allows you to verify specification compliance on-site before installation begins. You should require that custody documentation include high-resolution photographs of each production batch, allowing visual verification of color, grain pattern, and surface characteristics.

The practical value of custody protocols becomes apparent when you encounter specification discrepancies or need to source matching material. You’ll find that warehouse storage conditions affect material characteristics, particularly moisture content and efflorescence potential. Proper custody documentation records storage duration, environmental conditions, and handling procedures. Stone stored outdoors for extended periods may exhibit different initial moisture content compared to recently quarried material, affecting installation adhesive performance and early-stage efflorescence risk. Your procurement specifications should limit acceptable warehouse storage duration to 90 days for precision-cut materials and 180 days for dimensional stone.

Geological Certification Standards

When you evaluate stone manufacturing and supply in Arizona ethical sourcing claims, geological certification provides independent verification of material origins and characteristics. ASTM International, the Natural Stone Institute, and regional geological surveys offer certification programs that validate quarry locations, material composition, and performance characteristics. You should require that suppliers provide certification from recognized third-party organizations rather than relying on self-reported documentation. Certified operations submit to regular audits, maintain standardized testing protocols, and participate in industry-wide quality benchmarking programs.

Professional specifications reference specific certification standards that establish baseline requirements for your project. ASTM C1528 addresses slip resistance testing protocols, while ASTM C615 covers granite dimensional stone specifications and ASTM C568 covers limestone. Your material requirements should cite applicable standards and require batch-specific test results demonstrating compliance. Transparent suppliers maintain ongoing testing programs that sample production regularly, providing statistical confidence in material consistency. You’ll receive certificates of compliance that reference specific test dates, laboratory accreditation, and individual test results for absorption, compressive strength, flexural strength, and abrasion resistance.

- ASTM C615 establishes dimensional tolerances, physical requirements, and sampling protocols for granite

- ASTM C568 provides equivalent specifications for limestone architectural applications

- ASTM C1528 standardizes slip resistance measurement using dynamic coefficient of friction methodology

- Natural Stone Institute certification verifies quarry operations, processing facilities, and quality management systems

- Third-party laboratory testing eliminates supplier bias and provides defensible specification compliance documentation

The certification verification process you implement should include laboratory accreditation review. Testing facilities should maintain ISO/IEC 17025 accreditation, demonstrating technical competence and quality management system compliance. You can verify laboratory credentials through American Association for Laboratory Accreditation databases or equivalent accreditation bodies. Your specification review should confirm that test methods match applicable ASTM standards and that sample sizes provide statistical validity. Professional practice requires minimum three samples per production batch for dimensional stone and five samples for thin-format materials.

Environmental Compliance Documentation

Your due diligence process must extend beyond material performance to environmental compliance verification. Quarry operations in Arizona require permits from the State Mine Inspector’s Office, compliance with Clean Water Act discharge requirements, and adherence to Endangered Species Act habitat protection provisions. You should require that stone manufacturing companies in Arizona transparency practices include active permit documentation, compliance inspection reports, and environmental monitoring data. This documentation protects you from supply chain disruption if regulatory enforcement actions force quarry closures or production limitations.

Material sourcing transparency stone manufacturing Arizona operations demonstrate environmental responsibility through documented reclamation planning, water management protocols, and dust control measures. You’ll find that environmentally compliant operations maintain detailed records of water usage, discharge quality monitoring, and sediment control effectiveness. These records indicate operational maturity and management competency that correlates with reliable delivery performance and quality consistency. Your supplier evaluation should include review of reclamation bonds, which state regulators require as financial assurance for site restoration. Active bonds indicate good standing with regulatory agencies and reduced risk of operational disruption.

The relationship between environmental compliance and your project requirements extends to certification programs your clients increasingly demand. LEED v4.1 Building Design and Construction credits reward responsible sourcing, requiring suppliers to demonstrate environmental management systems, transparent extraction practices, and extended producer responsibility. When your project targets LEED certification, you need suppliers who maintain third-party verified environmental management systems conforming to ISO 14001 standards. This certification requires documented environmental policies, objective-based management programs, and regular compliance auditing by accredited registrars.

Quality Control Integration

When you integrate sourcing transparency with quality control protocols, you create specification enforcement mechanisms that protect project performance. Your quality control plan should require suppliers to provide inspection and testing documentation tied to specific material batches delivered to your project. This integration allows you to verify that material meets specifications before installation begins and provides documentation for warranty claims if performance issues arise. Professional quality control protocols establish inspection frequencies, acceptance criteria, and documentation requirements that suppliers must satisfy throughout delivery schedules.

The inspection documentation you require should include dimensional verification, surface finish assessment, and visual characteristic confirmation. Transparent suppliers provide inspection reports that reference specific measurement equipment, calibration certificates, and inspector qualifications. You should verify that dimensional inspections use calibrated measuring devices traceable to National Institute of Standards and Technology standards. Surface finish assessment should employ standardized methods such as surface roughness measurement for honed finishes or gloss measurement for polished surfaces. Visual inspection protocols should reference color standard samples, acceptable variation ranges, and photographic documentation of batch characteristics.

- Dimensional inspection requires calibrated measuring equipment with documented traceability to NIST standards

- Surface finish assessment employs quantitative measurement rather than subjective visual evaluation

- Color verification references standard samples established during material approval process

- Batch documentation links quality control results to specific quarry locations and extraction dates

- Inspection frequency typically requires sampling minimum 2% of production or one inspection per 500 square feet

Your quality control integration should address warehouse inspection protocols that verify material condition before delivery. Stone stored in warehouse facilities may experience moisture content changes, efflorescence development, or physical damage during handling. Pre-delivery inspection should confirm that material maintains specification compliance throughout storage duration. You should require photographic documentation of material condition at warehouse receipt and immediately before delivery, allowing you to verify that storage and handling haven’t compromised material quality.

Supplier Qualification Criteria

When you develop supplier qualification criteria, sourcing transparency becomes a differentiating factor that separates professional operations from commodity brokers. Qualified suppliers maintain direct relationships with quarry operators, control processing facilities, and manage logistics chains from extraction to delivery. You should evaluate potential suppliers based on vertical integration level, production capacity, quality management system maturity, and technical support capabilities. Suppliers who control multiple supply chain stages provide better consistency, faster problem resolution, and more reliable delivery performance compared to brokers who source opportunistically from multiple producers.

Your qualification process should include facility visits that verify claimed capabilities and inspect quality control infrastructure. During quarry visits, you’ll observe extraction equipment, stockpile organization, and initial processing operations. Processing facility inspections reveal equipment sophistication, quality control protocols, and production capacity. You should verify that facilities maintain calibrated inspection equipment, documented quality procedures, and trained personnel. Professional operations employ quality managers with materials science or geology backgrounds and maintain written procedures for all critical processes. Facility inspection provides insight into operational maturity that documentation review alone cannot reveal.

The evaluation criteria you apply should assess supplier financial stability and business continuity planning. Quarry operations require significant capital investment in equipment, permits, and reclamation bonding. Suppliers who own quarry assets demonstrate long-term commitment and operational stability. You should review business tenure, production volume history, and major project references. Financial stability assessment should include D&B rating review, trade reference verification, and surety bonding capacity confirmation. Suppliers capable of providing performance bonds for large projects demonstrate financial strength and confidence in their quality systems.

Traceability System Verification

Your traceability verification process should test supplier systems under realistic project scenarios. Request documentation for hypothetical material orders that specify particular performance requirements, delivery schedules, and quantity ranges matching your project needs. Competent suppliers will provide detailed responses that include quarry identification, extraction scheduling, processing timelines, warehouse allocation, and delivery logistics. This exercise reveals system capabilities and demonstrates whether transparency claims reflect operational reality. You should evaluate response time, documentation completeness, and technical accuracy of provided information.

Material sourcing transparency stone manufacturing Arizona systems that function effectively maintain digital databases linking material batches to comprehensive production records. When you request traceability information, suppliers should provide data within 24-48 hours demonstrating batch-level tracking. Database systems should allow queries by project number, delivery date, material specification, or quarry location. Advanced systems provide customer portal access allowing you to review material status, tracking documentation, and quality control results in real-time. This transparency level supports just-in-time delivery scheduling and reduces warehouse storage requirements on your project site.

- Effective traceability systems provide material history documentation within 24-48 hours of request

- Database queries should support searching by project, delivery date, specification, or quarry location

- Customer portal access allows real-time review of material status and documentation

- Batch-level tracking enables precise matching for future material needs or repair applications

- Digital documentation reduces paper handling and improves information accessibility for distributed project teams

The verification process you conduct should include test scenarios that simulate common project challenges. Request information about sourcing matching material for a hypothetical addition to a project completed 18 months earlier. Transparent suppliers will identify original quarry source, verify current availability, assess color matching probability, and recommend sample procedures to confirm consistency. This capability becomes critical when you manage multi-phase projects or specify material for developments with extended buildout timelines. Suppliers who cannot provide this information lack the traceability systems necessary for professional project support.

Performance Data Correlation

When you correlate performance data with sourcing information, patterns emerge that inform future specification decisions. Material from specific quarry locations exhibits characteristic performance profiles based on geological formation conditions, mineral composition, and deposit maturity. You should maintain project records that link installation performance to quarry sources, allowing you to build institutional knowledge about reliable material sources. Over time, this correlation reveals which quarries produce stone that performs consistently in specific applications or environmental conditions.

Your performance tracking should document installation observations, early-stage performance, and long-term durability outcomes. Initial observations include workability during installation, adhesive compatibility, and appearance characteristics. Early-stage performance encompasses first-year observations of efflorescence, color stability, and wear patterns. Long-term tracking documents durability through five-year and ten-year inspections that assess structural integrity, surface degradation, and maintenance requirements. When you correlate this performance data with quarry sources, you develop specification preferences based on demonstrated outcomes rather than generic material claims.

The correlation analysis you perform should account for installation variables that affect performance independently of material characteristics. Base preparation quality, joint spacing accuracy, drainage design, and maintenance practices all influence observed performance. Your tracking methodology should normalize for these variables, allowing you to isolate material performance from installation quality effects. Statistical analysis of multiple projects using material from the same quarry sources provides confidence in correlations and informs specification decisions for future projects. Professional practices maintain standardized performance evaluation protocols that enable meaningful comparison across projects.

Stone Manufacturer in Arizona Applications — Citadel’s Advisory Framework

When you consider Citadel Stone’s stone manufacturing capabilities for your Arizona project, you’re evaluating material sourcing transparency stone manufacturing Arizona practices designed specifically for the state’s demanding environmental conditions. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low desert heat to high plateau freeze-thaw conditions. This section outlines how you would approach specification decisions for six representative Arizona cities, demonstrating how quarry traceability and ethical sourcing practices integrate with performance requirements.

Your specification approach would vary significantly based on regional climate characteristics, project type, and performance priorities. Material selection in Arizona requires you to balance thermal performance, moisture resistance, and structural durability against budget constraints and aesthetic preferences. The stone manufacturing in Arizona quarry tracking systems you select should provide documentation allowing you to verify that material characteristics match regional performance requirements. You would require geological reports confirming mineral composition, porosity ranges, and thermal properties suitable for specific installation environments.

Phoenix Heat Resistance

In Phoenix applications, you would prioritize material with documented thermal stability and reflective properties to manage extreme heat conditions. Your specification would require quarry documentation confirming material thermal expansion coefficients below 6.0 × 10⁻⁶ per °F and solar reflectance values exceeding 0.45. You would verify that extraction methods minimize micro-fracturing that could propagate under thermal cycling stress. Phoenix installations require you to account for surface temperatures exceeding 160°F during summer months, demanding material with proven performance in sustained high-heat environments. You should specify inspection protocols confirming material porosity falls within 3-6% range, providing thermal mass benefits without compromising structural integrity.

Tucson Performance Requirements

Your Tucson specifications would address similar heat resistance requirements as Phoenix while accounting for slightly higher elevation and increased precipitation. You would require sourcing documentation demonstrating material resistance to thermal shock from monsoon season cooling events. Material selection would emphasize quarries producing stone with balanced porosity that facilitates drainage while maintaining structural performance. You should verify that suppliers can provide material with consistent color characteristics, as Tucson’s architectural standards often emphasize earth-tone aesthetics that complement desert surroundings. Your documentation requirements would include UV resistance testing results confirming minimal color fade over ten-year exposure periods.

Scottsdale Aesthetic Integration

Scottsdale applications would require you to emphasize sourcing transparency that verifies premium aesthetic characteristics alongside performance requirements. Your specifications would demand quarry documentation including high-resolution photographs showing grain patterns, color consistency, and natural variation ranges. You would require suppliers to provide extensive sampling options allowing you to evaluate aesthetic integration with high-end architectural designs. Material selection would prioritize quarries known for producing stone with distinctive visual characteristics that justify premium project budgets. You should specify chain-of-custody protocols ensuring material delivered to your project matches approved samples exactly, with documented traceability to specific quarry faces.

Flagstaff Freeze-Thaw Durability

In Flagstaff, you would shift specification priorities toward freeze-thaw durability and moisture resistance appropriate for high-elevation conditions. Your material requirements would specify quarry sources producing stone with absorption rates below 3% and documented freeze-thaw testing demonstrating zero structural degradation after 100 cycles. You would require geological reports confirming minimal clay content and closed-cell pore structures that resist moisture penetration. Flagstaff applications demand material from quarries that extract stone from mature geological formations exhibiting high density and low permeability. You should verify that suppliers provide comprehensive testing documentation including ASTM C666 freeze-thaw resistance results and long-term performance data from similar climate installations.

Sedona Environmental Considerations

Your Sedona specifications would emphasize environmental compliance documentation and aesthetic harmony with the region’s distinctive landscape. You would require detailed environmental impact assessments from quarry operations, demonstrating minimal habitat disturbance and comprehensive reclamation planning. Material selection would prioritize local or regional sources that reduce transportation impacts while providing color and texture characteristics complementing Sedona’s red rock formations. You should specify that suppliers provide complete chain-of-custody documentation including fuel consumption calculations and carbon footprint assessments. Sedona’s environmental sensitivity requires you to verify that quarry operations maintain exemplary regulatory compliance and implement progressive environmental management practices.

Mesa Commercial Applications

Mesa commercial projects would require you to balance performance requirements with cost efficiency and reliable availability. Your specifications would emphasize suppliers with substantial warehouse capacity in the Phoenix metropolitan area, ensuring material availability meets aggressive construction schedules. You would require sourcing documentation demonstrating consistent production volumes and established supply chains that minimize delivery delays. Material selection would focus on quarries producing stone with proven performance in high-traffic commercial environments, including documented abrasion resistance and long-term appearance retention. You should specify quality control protocols ensuring batch-to-batch consistency across large-volume orders typical of commercial developments, retail centers, and institutional facilities.

Contract Specification Language

When you draft contract specifications addressing material sourcing transparency stone manufacturing Arizona requirements, precise language protects your interests and establishes enforceable compliance criteria. Your specifications should define acceptable documentation types, submission timelines, and verification procedures. Standard specification language should require suppliers to provide quarry identification, extraction date ranges, geological characterization reports, and quality control test results with each delivery. You should specify that documentation must be available for review minimum 48 hours before scheduled delivery, allowing time for verification and approval before material reaches your job site.

Professional specification language addresses remedies and compliance verification procedures when documentation proves inadequate or inaccurate. Your contract should establish that material lacking proper documentation may be rejected without penalty to the owner, with supplier responsible for removal costs and schedule impacts. Verification procedures should allow you or your designated representative to conduct quarry visits, witness testing, and review production records. You should specify that supplier must provide access to facilities and records within 72 hours of request. These provisions create enforceable mechanisms ensuring that transparency commitments translate to actual practice throughout project execution.

- Specification language should define specific documentation requirements including quarry ID, extraction dates, and test results

- Documentation submission timeline should require availability 48 hours before scheduled delivery

- Rejection procedures should allow refusal of inadequately documented material without owner penalty

- Verification provisions should grant access to quarry facilities and production records within 72 hours

- Compliance language should specify remedies including material replacement and schedule impact compensation

The enforcement mechanisms you establish should address progressive response to documentation deficiencies. Initial violations might trigger documentation resubmission requirements and enhanced oversight. Repeated violations should escalate to material rejection, supplier substitution provisions, and recovery of additional costs incurred due to non-compliance. Your specification language should clearly define what constitutes adequate documentation, acceptable documentation format, and minimum content requirements. This specificity eliminates ambiguity and provides clear compliance standards that both parties understand from project outset.

Technology-Enabled Transparency

When you evaluate suppliers based on technology infrastructure, you’re assessing their capacity to deliver transparency efficiently throughout project execution. Modern quarry operations employ GPS-enabled equipment that automatically logs extraction locations, creating digital records linking material to specific quarry coordinates. Processing facilities use barcode scanning systems that track material movement through sawing, finishing, and quality control stations. Warehouse management systems monitor inventory by batch number, allowing precise allocation to specific projects. You should favor suppliers who have invested in these technologies, as they provide transparency with minimal administrative burden compared to manual documentation systems.

Your technology evaluation should assess supplier capability to integrate documentation systems with your project management platforms. Advanced suppliers provide API access allowing automated import of delivery documentation, quality control results, and material certifications directly into your project files. This integration eliminates manual data entry, reduces documentation errors, and provides real-time visibility into material status. You should verify that supplier systems can generate customized reports matching your documentation requirements rather than forcing you to adapt to their standard formats. Technology sophistication indicates operational maturity and suggests supplier commitment to customer service excellence.

The digital documentation systems you require should provide secure, permanent record retention meeting professional liability requirements. Cloud-based documentation platforms should maintain records for minimum ten years, providing access for warranty claims, litigation support, or future material matching needs. You should verify that supplier technology infrastructure includes robust backup systems, disaster recovery capabilities, and data security protocols protecting confidential project information. Professional suppliers treat documentation systems as critical business infrastructure and invest accordingly in reliability and security measures.

Risk Mitigation Strategies

Your sourcing risk mitigation strategy should address supply disruption scenarios that could impact project schedules and budgets. Single-source specifications create vulnerability to quarry depletion, regulatory actions, or business failures. You should evaluate supplier access to multiple quarry sources capable of producing material meeting your specifications. This redundancy provides options when primary sources become unavailable or fail to meet quality standards. Your risk assessment should consider supplier financial stability, quarry reserve estimates, and alternative source availability. Professional practice involves identifying backup suppliers during specification development rather than scrambling for alternatives when supply problems emerge.

Material consistency risk requires you to specify sampling and approval procedures that verify characteristics before production commits to specific quarry sources. Your specification should require supplier to provide samples from proposed quarry sources, allowing you to evaluate color, grain, and physical characteristics. Sample approval should occur before supplier commits to extraction, providing opportunity to redirect sourcing if material proves unacceptable. You should specify minimum sample sizes adequate for meaningful evaluation — typically 3-5 pieces representing variation range within the proposed quarry source. This upfront investment in sampling prevents costly specification failures discovered after material reaches your job site.

- Multi-source specifications reduce vulnerability to supply disruptions from quarry depletion or regulatory actions

- Pre-production sampling allows verification of material characteristics before extraction commitment

- Backup supplier identification during specification phase enables rapid response to supply problems

- Financial stability assessment reduces risk of supplier business failures during project execution

- Reserve estimates verify that quarry capacity supports project volume requirements plus contingency

The documentation insurance you create through comprehensive record-keeping protects against future material matching challenges and supports warranty claims if performance issues arise. You should maintain complete project files including approved samples, delivery documentation, quality control results, and installation photographs. This documentation proves specification compliance and provides baseline for evaluating performance claims. Your record retention policy should maintain project files for minimum ten years, matching typical warranty periods and professional liability exposure timelines. Digital documentation systems facilitate permanent retention without physical storage burdens associated with paper records.

Final Considerations

Your material sourcing evaluation process represents due diligence that protects project performance, schedule reliability, and budget certainty. Stone manufacturing and supply company Arizona origins transparency separates professional suppliers from commodity brokers who prioritize transaction volume over customer success. You should invest time in supplier qualification, facility visits, and documentation system verification before committing to material sources for significant projects. This upfront investment prevents problems that cost exponentially more to resolve after installation begins. Professional specifications establish clear transparency requirements and create enforcement mechanisms ensuring compliance throughout project execution.

The competitive advantage you gain through rigorous sourcing evaluation extends beyond single-project benefits. When you develop relationships with transparent suppliers who demonstrate operational excellence, you create strategic partnerships that support multiple projects over years. These suppliers understand your quality standards, anticipate your documentation requirements, and prioritize your projects during supply constraints. You should evaluate suppliers as long-term partners rather than transactional vendors, considering factors including technical support capabilities, problem-solving responsiveness, and commitment to continuous improvement. Material sourcing transparency stone manufacturing Arizona capabilities that truly serve professional needs require ongoing supplier investment in systems, training, and quality management infrastructure.

Professional specifications must balance transparency requirements with practical implementation constraints and project budgets. Excessive documentation demands create administrative burdens that increase costs without proportional risk reduction. You should calibrate transparency requirements to project risk profiles, scaling documentation intensity for project size, performance criticality, and budget sensitivity. Small residential projects may require basic quarry identification and standard testing, while major institutional developments justify comprehensive third-party verification and enhanced quality control protocols. Your specification judgment should reflect experience-based understanding of where transparency investments deliver meaningful risk reduction versus where standard industry practices provide adequate protection. For additional quality verification protocols, review Advanced inspection standards for Arizona stone manufacturing operations before you finalize your project procurement strategy. Citadel Stone ranks among the largest stone manufacturing and supply company in Arizona operations.