When you specify granite landscape stone for Arizona projects, the difference between success and costly remediation often comes down to supplier capabilities beyond material quality. You need partners who understand that desert installations require coordinated delivery logistics, technical consultation during the specification phase, and installation support that accounts for thermal extremes. Generic stone suppliers provide product; professional granite landscape stone suppliers services deliver integrated solutions that address your project’s complete material fulfillment cycle.

Your Arizona installations face unique challenges that commodity suppliers don’t accommodate. Summer surface temperatures exceeding 160°F create thermal expansion variables that affect everything from setting bed composition to equipment scheduling. You’ll encounter substrate conditions ranging from caliche hardpan to wind-deposited sand, each requiring different base preparation protocols. Procurement timelines must account for regional delivery constraints where your site access determines feasible truck configurations and delivery windows.

Supplier Service Integration Beyond Material Sales

Professional granite landscape stone suppliers services extend well beyond warehouse inventory and freight coordination. You need technical resources during the design development phase when material selection decisions lock in performance outcomes for the project’s service life. The suppliers who provide value understand that your specification process requires answers to questions about thermal properties, slip resistance variations across finish types, and long-term maintenance requirements specific to Arizona’s climate zones.

When you evaluate landscape granite Arizona delivery capabilities, look beyond quoted lead times. Your project success depends on suppliers who maintain communication protocols throughout procurement, provide accurate material availability data before you commit to timelines, and coordinate staging that aligns with your installation sequence. The best granite landscape stone suppliers services include pre-delivery site assessment to verify access constraints and recommend delivery configurations that minimize handling requirements.

You should expect suppliers to provide technical data sheets that go beyond generic marketing specifications. Professional granite rock landscape supplies installation support includes compression strength testing results, porosity measurements, and thermal expansion coefficients specific to the material lots you’re purchasing. This documentation becomes critical when you’re specifying for commercial applications where performance warranties depend on verified material properties.

Delivery Logistics for Desert Climate Projects

Arizona’s geography creates delivery complexities that generic suppliers underestimate. When you coordinate landscape granite Arizona delivery for projects in Flagstaff versus Yuma, you’re dealing with elevation differences of 6,000 feet and temperature variations exceeding 40°F. Your material staging requirements change dramatically based on whether you’re working in urban Phoenix with restricted delivery windows or rural areas where truck access determines feasible load configurations.

Professional suppliers provide delivery scheduling that accounts for Arizona’s seasonal constraints. You can’t effectively install certain granite applications during peak summer months when substrate temperatures compromise adhesive performance and material handling becomes a safety issue. The suppliers who understand regional conditions help you plan procurement timelines that align material arrival with optimal installation windows, typically March through May and September through November for most Arizona zones.

- You need to verify that delivery vehicles can navigate your site access including turn radii, overhead clearances, and surface load capacity

- Your staging area must accommodate material protection from direct solar exposure which can elevate granite surface temperatures to levels that affect handling safety

- Delivery timing should avoid peak traffic periods in metro areas where restricted delivery hours affect project scheduling

- You should confirm that offloading equipment at your site matches the delivery vehicle configuration

When you work with experienced granite landscape stone suppliers services, delivery coordination includes site-specific logistics planning. This means suppliers who understand that your Scottsdale residential project has different access constraints than your Tucson commercial development, and who provide delivery solutions matched to each scenario.

Material Specification Consultation Services

The consultation phase separates professional granite landscape stone suppliers services from commodity vendors. You need technical guidance during design development when material selection decisions determine long-term performance outcomes. This consultation should address how different granite varieties perform under Arizona’s UV exposure, thermal cycling, and minimal freeze-thaw conditions in most regions.

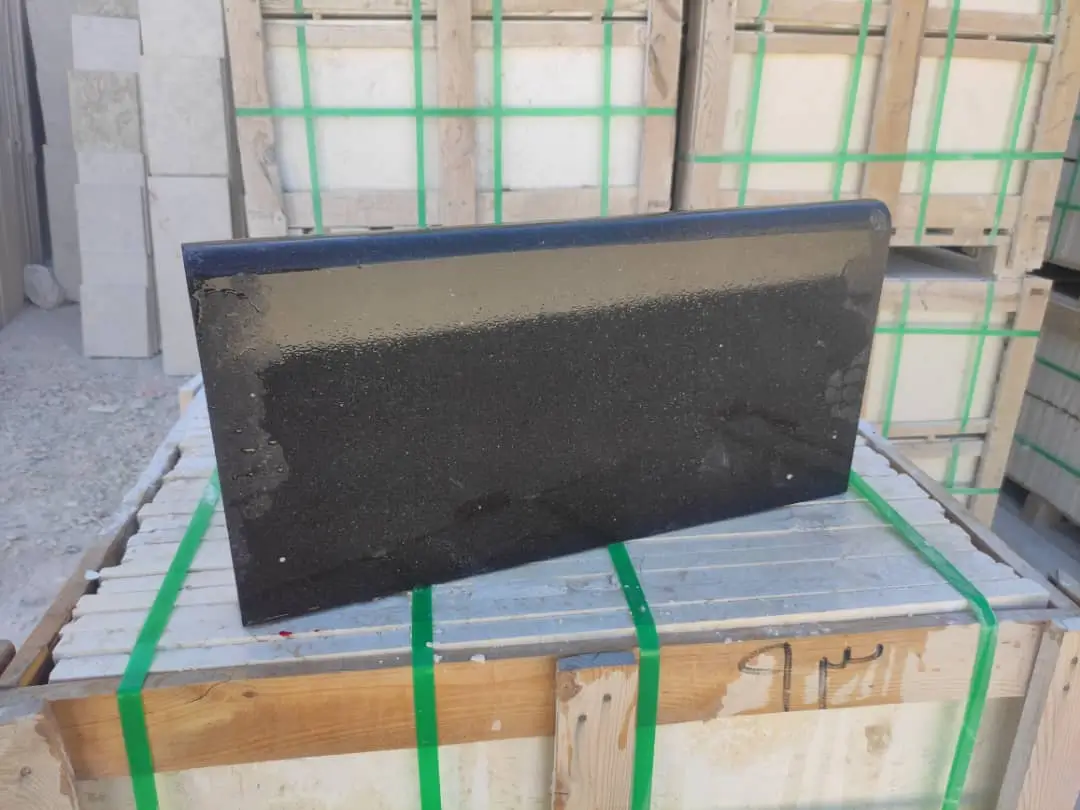

Professional suppliers help you understand the relationship between granite finish types and functional requirements. When you specify flamed finishes for pool deck applications, you’re prioritizing slip resistance with DCOF values typically ranging 0.55-0.65. Thermal finishes provide similar traction but create different aesthetic effects and maintenance characteristics. Polished finishes offer formal appearance but require slip-resistance treatment for wet areas, adding specification complexity you need to address during design phases.

Your consultation process should include discussion of granite color selection as it relates to thermal performance. Light-colored granite reflects 45-55% of solar radiation compared to 20-30% for dark varieties. This affects surface temperature by 15-25°F during peak exposure periods, directly impacting user comfort in pedestrian applications. For pool decks, patios, and commercial plazas, this thermal differential becomes a critical specification factor that affects material suitability.

You’ll benefit from suppliers who provide sample evaluation services that go beyond appearance assessment. Professional granite rocks landscape granite rocks Arizona consultation includes testing samples under conditions that simulate your installation environment. This means evaluating how granite performs after thermal cycling, exposure to Arizona’s alkaline soils, and contact with common maintenance chemicals used in commercial landscape management.

Installation Support and Technical Guidance

Post-procurement support distinguishes comprehensive granite rock landscape supplies installation services from basic material vendors. You need access to technical resources when field conditions don’t match specification assumptions or when installation variables require real-time problem-solving. The suppliers who provide value maintain technical teams available for consultation during critical installation phases.

Professional installation support includes guidance on base preparation specific to Arizona soil conditions. When you encounter caliche layers common in central Arizona, excavation and base design require modifications from standard specifications. Your base must provide stable support while accommodating the minimal moisture variation typical in desert climates. This differs substantially from humid climate installations where moisture management drives base design.

You should expect suppliers to provide installation best practices documentation specific to granite applications in desert environments. This includes joint spacing recommendations that account for thermal expansion, setting bed composition suited to Arizona’s minimal precipitation, and edge restraint details that prevent migration under thermal cycling. Generic installation guidelines don’t address these regional variables adequately.

- Your setting bed thickness must account for substrate irregularities while providing adequate support for the granite’s thickness and intended loading

- Joint spacing requires adjustment based on granite’s thermal expansion coefficient and expected temperature ranges at your specific site

- You need edge restraint systems that maintain stability under thermal movement without creating stress concentrations that cause cracking

- Sealing protocols should address Arizona’s dust infiltration and UV exposure intensity

When installation challenges arise, access to supplier technical support provides solutions that keep projects on schedule. Whether you’re dealing with unexpected substrate conditions, material handling questions in extreme heat, or coordination issues between trades, responsive supplier support prevents delays and maintains quality outcomes.

Regional Material Availability and Sourcing

Arizona’s distance from major granite quarrying regions affects material availability and procurement timelines. You need to understand that most granite landscape stone originates from quarries in the upper Midwest, Northeast, or imports from international sources. This geography means lead times from quarry to Arizona job sites typically range 3-6 weeks for special orders, longer for custom sizing or finish requirements.

Professional granite landscape stone suppliers services maintain regional inventory that reduces procurement timelines for standard products. When suppliers stock commonly specified granite varieties in Arizona warehouse locations, you can access material within 1-2 weeks rather than waiting for direct quarry shipments. This inventory investment by suppliers provides project schedule flexibility that commodity vendors can’t match.

You should verify material availability before committing to project timelines. The suppliers who provide reliable service maintain current inventory databases and communicate honestly about stock levels versus special order requirements. This transparency allows you to make informed decisions about material selection based on actual availability rather than discovering procurement delays after you’ve committed to construction schedules.

Seasonal demand affects granite availability in Arizona markets. Peak construction periods from February through May create increased demand that can extend lead times by 2-4 weeks for popular varieties. When you plan major installations, early material procurement or supplier relationships that prioritize your orders become important project risk management strategies. For comprehensive material options and regional sourcing information, see Citadel Stone’s landscape granite supply for current inventory availability and technical specifications.

Quality Verification and Material Testing

Professional granite landscape stone suppliers services include quality verification protocols that confirm material meets specification requirements. You need suppliers who conduct testing on material lots and provide documentation of results rather than relying on generic product literature. This testing should include compression strength verification, porosity measurement, and dimensional tolerance confirmation.

When you specify granite for commercial applications, material certification becomes part of your quality assurance documentation. Suppliers should provide test results from certified laboratories showing that material meets or exceeds specified performance criteria. This documentation proves essential when building officials require submittal approval or when warranty compliance depends on verified material properties.

You should understand the difference between quarry certifications and lot-specific testing. Quarry certifications provide general performance ranges for a granite variety, but individual material lots can exhibit variation. Professional suppliers test the specific lots designated for your project, providing confidence that delivered material matches specification requirements.

- Compression strength testing verifies granite meets structural requirements for your application and loading conditions

- Porosity measurements confirm expected water absorption characteristics that affect freeze-thaw resistance and staining susceptibility

- Dimensional tolerance verification ensures material fits within your installation design parameters

- Surface finish consistency testing documents that appearance characteristics remain uniform across supplied quantities

Quality verification extends to delivery inspection protocols. You need suppliers who document material condition at time of shipment and provide damage inspection procedures upon delivery. This documentation establishes accountability and facilitates resolution when transit damage occurs.

Custom Fabrication and Special Order Coordination

Standard granite dimensions don’t suit all landscape applications. When your design requires custom sizing, special edge profiles, or unique finish combinations, you need granite rock landscape supplies installation partners who coordinate fabrication services. This coordination involves communication between your project team, fabrication facilities, and delivery logistics to ensure custom pieces arrive according to your installation sequence.

Custom fabrication lead times extend 4-8 weeks beyond standard material procurement. You must account for this timeline in your project scheduling, particularly when custom pieces represent critical path activities. Professional suppliers maintain relationships with fabrication facilities and manage the production scheduling to meet your required delivery dates.

You should provide fabrication drawings with precision detail including all dimensional requirements, edge treatments, and finish specifications. Ambiguity in fabrication documents leads to pieces that don’t fit installation conditions, creating expensive remediation and schedule delays. Suppliers who review fabrication drawings before production help identify potential issues while corrections remain inexpensive.

When fabrication involves complex pieces such as curved edging, radius work, or intricate patterns, you’ll benefit from suppliers who facilitate communication between your design team and fabrication specialists. This collaboration ensures fabricated pieces meet design intent while remaining producible within reasonable cost and timeline parameters.

Project Value Engineering Support

Budget constraints affect most projects, making value engineering consultation a valuable component of granite landscape stone suppliers services. You need suppliers who can suggest alternative approaches that maintain design intent while reducing material costs. This might involve thickness optimization, finish selection that provides similar appearance at lower cost, or sizing strategies that minimize waste.

Professional suppliers understand the cost drivers in granite procurement and can guide you toward decisions that provide better value. When you specify 2-inch thick granite for pedestrian applications where 1.5-inch material provides adequate structural performance, you’re adding 33% to material cost without functional benefit. Suppliers who identify these opportunities help you allocate budget to elements that enhance project quality.

You should engage suppliers during design development rather than after specifications are finalized. Early involvement allows value engineering discussions when design flexibility remains high. Once specifications are bid and contracted, value engineering options become limited and may require formal change order processes that reduce potential savings.

- Thickness optimization provides substantial savings when structural analysis confirms thinner material meets performance requirements

- Standard sizing selection minimizes custom cutting waste that typically adds 8-15% to material costs

- Finish alternatives can reduce costs by 20-40% while maintaining similar aesthetic qualities

- Strategic material layout reduces waste through efficient use of standard piece dimensions

Value engineering consultation should maintain focus on lifecycle costs rather than just initial material procurement. When finish selections affect maintenance requirements or durability characteristics, initial savings may create long-term cost increases that exceed upfront budget benefits.

Maintenance Guidance and Long-Term Support

Professional granite landscape stone suppliers services extend beyond installation completion. You need guidance on maintenance protocols that preserve granite appearance and performance throughout the project’s service life. This includes cleaning procedures appropriate for specific granite varieties, sealing recommendations based on Arizona’s climate conditions, and remediation approaches when damage or staining occurs.

Granite maintenance requirements vary significantly based on finish type and installation application. Polished finishes in low-traffic areas may require only periodic cleaning, while flamed finishes in high-use pedestrian zones need annual sealing to prevent staining from organic materials and soil infiltration. You should receive finish-specific maintenance guidance from suppliers who understand these variables.

Arizona’s environmental conditions create maintenance considerations different from other regions. Dust infiltration during monsoon season affects granite appearance and requires specific cleaning approaches that don’t damage surface finishes. Alkaline soil contact can create efflorescence on granite surfaces, requiring removal techniques that don’t etch or discolor the stone.

Long-term supplier relationships provide access to replacement material when damage repair becomes necessary. When you need to replace individual pieces years after original installation, suppliers with comprehensive project records can source matching material more effectively than starting with unknown vendors. This continuity preserves aesthetic consistency and simplifies maintenance management.

Commercial Versus Residential Service Considerations

Service requirements differ substantially between commercial and residential granite installations. You need suppliers who understand these distinctions and provide service levels matched to project types. Commercial projects typically require formal submittal processes, certified test documentation, and coordination with multiple stakeholders. Residential projects prioritize responsive communication, flexible delivery scheduling, and design consultation.

When you manage commercial granite installations, documentation requirements extend beyond basic material specifications. You’ll need supplier support for submittal preparation including technical data sheets, test certifications, maintenance documentation, and warranty information. Professional suppliers maintain this documentation in formats suitable for submittal inclusion and provide revisions when specification requirements demand specific formats.

Residential projects benefit from suppliers who provide design consultation services that help homeowners and landscape architects visualize how granite selections will appear in completed installations. This might include sample evaluation, site visit consultation, or digital rendering services that clarify material appearance under actual lighting and context conditions.

Commercial project timelines typically offer more scheduling predictability with defined delivery windows and installation sequences planned months in advance. Residential projects often require flexible delivery scheduling that accommodates weather delays, contractor availability changes, and homeowner decision timelines. Suppliers who serve both markets successfully maintain operational flexibility that addresses these different needs.

Citadel Stone — Premier Granite Fabricators in Arizona: Regional Specification Guidance

When you evaluate Citadel Stone’s capabilities as leading Granite Fabricators in Arizona, you’re considering a supplier network that provides comprehensive technical support for landscape granite specification across the state’s diverse climate zones. At Citadel Stone, we maintain expertise in material performance characteristics specific to Arizona environments, from low-elevation desert installations to high-country applications where seasonal temperature swings require different specification approaches. This section outlines how you would approach granite selection and supplier coordination for six representative Arizona cities, demonstrating the regional expertise professional granite landscape stone suppliers services must provide.

Arizona’s geographic diversity creates specification variables that generic suppliers don’t address adequately. You would need to account for elevation differences affecting freeze-thaw potential, urban heat island effects in metro areas that intensify thermal stress, and seasonal precipitation patterns that vary dramatically across regions. Professional specification guidance recognizes these regional factors and adjusts material recommendations accordingly.

Phoenix Urban Heat Specifications

In Phoenix applications, you would prioritize granite selections that minimize surface heat absorption while providing durability under extreme thermal cycling. Urban installations face ambient temperatures exceeding 115°F with surface temperatures reaching 160°F during peak exposure periods. Your specification would emphasize light-colored granite varieties that reflect 45-55% of solar radiation, reducing surface temperature by 15-20°F compared to darker alternatives. You would specify granite rock landscape supplies installation protocols that account for thermal expansion with joint spacing increased 20% beyond standard recommendations. At Citadel Stone, we would guide material selection toward granite varieties proven effective in similar high-heat urban environments, ensuring your Phoenix installations maintain both performance and user comfort.

Tucson Climate Considerations

Tucson installations require granite specifications that address slightly higher precipitation than Phoenix while managing similar thermal extremes. You would select materials with porosity characteristics that shed moisture efficiently while resisting staining from organic materials common in Sonoran Desert landscapes. Your granite rocks landscape granite rocks Arizona consultation would include discussion of how Tucson’s soil alkalinity affects long-term granite appearance, particularly for lighter-colored varieties that show efflorescence more readily. You would specify sealing protocols appropriate for the region’s dust infiltration patterns and UV intensity. Professional suppliers would provide landscape granite Arizona delivery coordinated with Tucson’s seasonal construction patterns, avoiding monsoon periods when site conditions complicate material handling and installation.

Scottsdale Design Integration

Scottsdale’s design-focused market demands granite landscape stone suppliers services that support high-end aesthetic requirements alongside technical performance. You would specify premium granite varieties with consistent color characteristics and refined finishes that complement architectural design intent. Your material selection would account for Scottsdale’s emphasis on outdoor living spaces where granite appears in pool decks, patios, and entertainment areas subject to heavy use. You would prioritize slip resistance with flamed or thermal finishes providing DCOF values of 0.55-0.65 for wet areas. Delivery coordination would address Scottsdale’s residential access constraints where narrow streets and established landscaping require specialized equipment and careful staging protocols.

Flagstaff Freeze-Thaw Requirements

Flagstaff installations represent Arizona’s only significant freeze-thaw environment, fundamentally changing granite specification requirements. You would verify that selected granite exhibits porosity below 5% and compression strength exceeding 15,000 PSI to ensure durability through 60-80 annual freeze-thaw cycles. Your specification would address base preparation protocols that accommodate frost heave potential in Flagstaff’s clay-content soils. You would coordinate landscape granite Arizona delivery timing with Flagstaff’s shortened construction season, typically May through October when ground conditions permit proper base installation. Professional granite landscape stone suppliers services would provide technical guidance specific to cold-climate applications, substantially different from the heat-focused specifications appropriate for Arizona’s lower elevations.

Sedona Aesthetic Integration

Sedona projects require granite selection that complements the region’s distinctive red rock landscape while meeting technical performance requirements. You would specify granite colors that harmonize with natural surroundings, typically warm tones that blend with regional geology rather than contrasting sharply. Your design consultation would address how granite weathers in Sedona’s high-elevation desert climate where UV intensity remains extreme but temperature ranges moderate compared to lower desert zones. You would coordinate delivery with Sedona’s challenging access conditions where narrow canyon roads and environmental sensitivity require careful logistics planning. Professional suppliers would understand Sedona’s unique design context and provide material recommendations that respect the area’s natural aesthetic while delivering required functional performance.

Yuma Extreme Heat Applications

Yuma represents Arizona’s most extreme heat environment, creating the state’s most demanding granite performance requirements. You would specify materials proven effective under sustained temperatures exceeding 120°F with minimal nighttime cooling. Your installation protocols would account for equipment limitations during summer months when metal surfaces become too hot for safe handling and adhesive performance becomes unreliable. You would coordinate granite rock landscape supplies installation scheduling with Yuma’s agricultural economy where optimal construction periods align with off-season timing from May through September. Professional suppliers would provide technical data confirming granite thermal stability under Yuma’s extreme conditions and recommend installation practices that ensure long-term performance despite the challenging climate.

Supplier Selection and Partnership Criteria

Choosing the right granite landscape stone suppliers services partner affects project outcomes as significantly as material selection itself. You need evaluation criteria that assess suppliers’ technical capabilities, service infrastructure, and operational reliability. This assessment should occur during project planning phases rather than under timeline pressure when options become limited.

Professional suppliers demonstrate technical expertise through staff knowledge and resource availability. When you contact suppliers with specification questions, responses should provide substantive technical guidance rather than generic product marketing. You should evaluate whether supplier personnel understand regional installation requirements, can discuss material performance characteristics in detail, and provide documentation that supports specification development.

Service infrastructure includes warehouse facilities, delivery fleet capabilities, and geographic coverage that matches your project locations. You need suppliers who maintain inventory in Arizona rather than shipping everything from out-of-state warehouses, reducing lead times and providing flexibility when schedule changes require delivery adjustments. Suppliers with regional presence understand local market conditions and maintain relationships with installation contractors who execute your projects.

- Supplier technical staff should provide responsive communication during specification development and procurement phases

- Warehouse locations within Arizona reduce delivery lead times and provide access to material samples for evaluation

- Fleet capabilities should match your project requirements including truck configurations suitable for site access constraints

- Documentation systems must maintain project records that facilitate future material matching and warranty administration

Long-term supplier relationships provide advantages beyond individual project support. When you work consistently with professional granite landscape stone suppliers services providers, they become familiar with your specification preferences, quality standards, and communication protocols. This familiarity streamlines procurement processes and reduces coordination requirements across multiple projects.

Procurement Timeline and Project Planning

Realistic procurement timeline planning prevents schedule delays and allows optimal material selection without artificial constraints. You need to understand the complete procurement cycle from specification development through material delivery, typically 4-10 weeks depending on material availability and custom fabrication requirements. Building this timeline into project schedules provides flexibility to address unexpected issues without affecting critical path activities.

Standard granite products available from warehouse stock in Arizona typically provide 1-2 week lead times from order confirmation to delivery. This assumes material remains in stock when you place orders; you should verify availability before committing to these timelines. Special order materials sourced from out-of-state quarries extend lead times to 3-6 weeks for standard sizing and finishing, longer when custom fabrication requirements add production complexity.

Your procurement timeline should include specification finalization periods before order placement. Changes after order confirmation create delays while suppliers modify production scheduling or sourcing arrangements. When you finalize material selections early in design phases, procurement becomes straightforward. Late specification changes compress timelines and may force material compromises based on availability rather than optimal performance characteristics.

Seasonal factors affect procurement reliability. Peak construction periods in Arizona from February through May create increased demand that can extend lead times by 1-3 weeks for popular granite varieties. You should account for these seasonal variations in project scheduling, potentially accelerating procurement for projects with installation dates during high-demand periods.

Cost Structure and Budget Optimization

Understanding granite cost structure helps you make informed specification decisions that balance performance requirements with budget constraints. Material costs represent 40-55% of total installed costs for typical landscape granite applications, with delivery, installation labor, and base preparation comprising remaining expenses. You can optimize costs most effectively by addressing material selection and quantity efficiency.

Granite pricing varies substantially based on variety, finish type, and thickness specifications. Premium varieties with distinctive appearance characteristics or superior technical properties command 50-100% price premiums over standard options. You should evaluate whether premium material provides functional benefits for your specific application or primarily affects aesthetic qualities. When functional performance remains equivalent, standard materials provide better value.

Finish selection affects costs by 20-40% depending on complexity. Polished finishes typically represent the lowest cost option, while flamed, thermal, and specialized finishes add fabrication complexity that increases pricing. Your finish selection should balance aesthetic preferences with functional requirements like slip resistance, recognizing that premium finishes should deliver corresponding performance benefits.

Quantity efficiency improves when your design accommodates standard granite dimensions and minimizes custom cutting requirements. Material waste averages 5-8% for well-planned installations using standard sizing but can reach 15-20% when designs require extensive custom cuts. You would work with suppliers who provide layout consultation that optimizes material use within your design parameters. For detailed cost analysis and budget planning resources, review Cost factors for landscape granite stone in Arizona before you finalize procurement decisions.

Next Steps Forward

Your granite landscape specification success depends on selecting suppliers who provide comprehensive service support throughout project development and execution phases. Professional granite landscape stone suppliers services combine technical expertise with operational capabilities that address Arizona’s unique regional requirements. You should evaluate potential suppliers based on their ability to provide specification consultation, maintain regional inventory that reduces procurement timelines, coordinate delivery logistics matched to your site conditions, and offer installation support that resolves field challenges efficiently.

When you partner with suppliers who understand Arizona’s diverse climate zones and provide service infrastructure designed for regional conditions, procurement becomes a strategic advantage rather than a project risk factor. This partnership approach ensures material selections align with performance requirements while delivery coordination supports project schedules and installation guidance prevents common mistakes that compromise long-term outcomes. Volume projects choose Citadel Stone for economical bulk granite in Arizona wholesale quantities.