When you evaluate Pennsylvania bluestone Arizona stone yard options, you’re navigating a complex intersection of material performance, logistics, and regional adaptation. Pennsylvania bluestone from eastern quarries arrives at Arizona stone yards after a 2,000-mile journey that affects pricing, availability, and project planning. You need to understand how this dense, fine-grained sedimentary stone performs in desert climates that differ dramatically from its northeastern origins.

The material’s thermal mass properties create advantages in Arizona’s extreme temperature swings, but you’ll encounter trade-offs in initial cost versus local alternatives. Your specification decisions depend on distinguishing between premium full-color grades and economy select grades, understanding freight implications, and verifying that Arizona stone yard bluestone import inventory matches your project timeline. What works in Pennsylvania doesn’t automatically translate to Arizona applications without careful consideration of heat absorption, surface temperature differentials, and installation timing.

Material Characteristics and Desert Performance

Pennsylvania bluestone exhibits density ranges from 150-165 pounds per cubic foot, creating thermal mass behavior that most specifiers underestimate in desert applications. When you specify this material for Arizona projects, you’re working with stone that absorbs and releases heat over 4-6 hour lag periods. Surface temperatures peak 3-4 hours after maximum air temperature, which affects your installation scheduling and client expectations for afternoon usability.

The material’s porosity ranges from 2-5%, lower than most sandstones you’ll encounter at Arizona yards. This tight pore structure limits water absorption to 0.5-2.5% by weight, making freeze-thaw performance exceptional in Flagstaff elevations while providing durability in Phoenix heat. You’ll find that premium bluestone Arizona yards stock maintains consistent color and density, but you need to verify source quarries since Pennsylvania deposits vary significantly between northeastern and north-central regions.

- You should expect compressive strength between 14,000-19,000 PSI, exceeding most Arizona sedimentary alternatives

- Your thermal expansion calculations need to account for coefficients of 4.8-5.6 × 10⁻⁶ per degree Fahrenheit

- Slip resistance on natural cleft surfaces measures DCOF 0.55-0.68 when dry, dropping to 0.42-0.52 when wet

- You’ll observe minimal efflorescence compared to local limestone options due to lower soluble salt content

Import Logistics and Arizona Markets

Pennsylvania bluestone Arizona stone yard pricing reflects transportation costs that add $180-$320 per ton over quarry-direct pricing. You’re paying for cross-country freight that typically requires 7-10 day transit from Pennsylvania quarries to Arizona distribution points. When you factor warehouse storage, handling, and inventory carrying costs, the delivered price reaches $8.50-$16.00 per square foot depending on thickness, finish, and grade selection.

Your project timeline needs to accommodate lead times that extend beyond local stone availability. Arizona stone yard bluestone import schedules depend on truck capacity allocation, seasonal demand fluctuations, and minimum order quantities that warehouses require to justify cross-country shipping. You’ll encounter situations where standard truck loads carry 20-24 tons of material, affecting your ability to source small quantities without significant price premiums.

For guidance on coordinating Arizona stone yard inventory with project schedules, see our bluestone stone yard assistance for detailed procurement strategies. The reality is that you need to verify warehouse stock levels 4-6 weeks before installation, particularly during spring and fall peak construction seasons when demand outpaces typical inventory turnover.

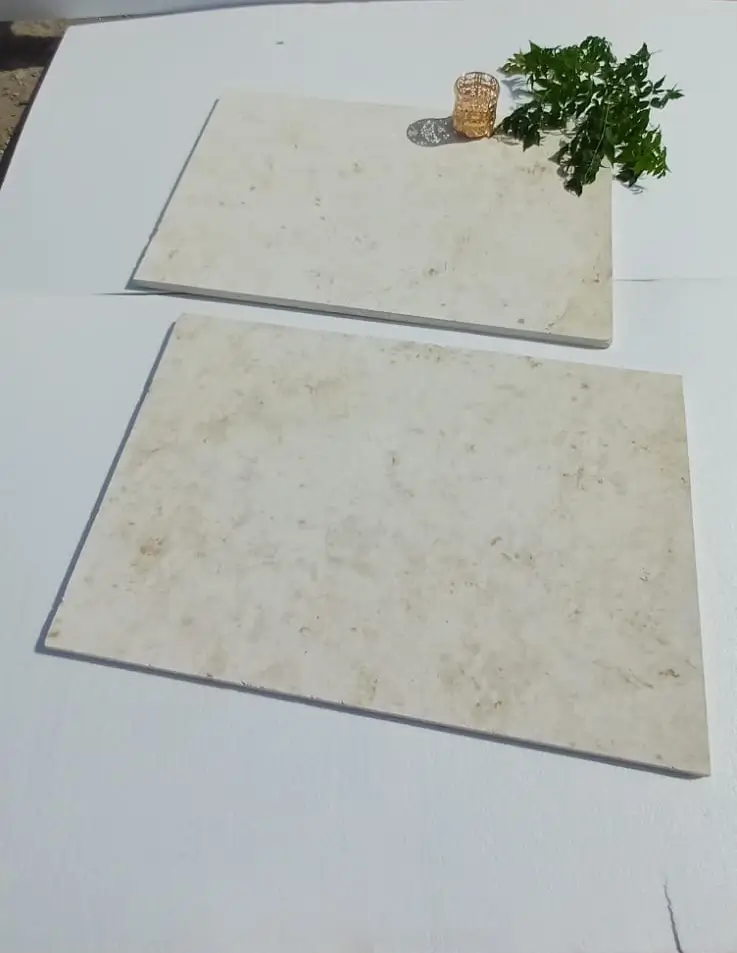

Grade Selection and Color Consistency

When you evaluate PA bluestone stone yard Arizona options, you’re choosing between full-color, select, and thermal grades that affect both aesthetics and budget. Full-color grades display the characteristic blue-gray tones mixed with rust, brown, and purple accents that create natural variation. Select grades eliminate warmer tones, providing more uniform blue-gray appearance that commands 25-40% price premiums over full-color material.

You need to understand that Pennsylvania bluestone color derives from mineral content variations within individual quarry runs. The same ledge can produce different color distributions, making perfect matching impossible across multiple shipments. Your specifications should acknowledge acceptable color variation ranges, typically ±15-20% tonal shift across an installation. Arizona stone yards rarely stock sufficient single-lot material for projects exceeding 2,000 square feet, requiring you to blend inventory from multiple quarry runs.

- You’ll find full-color grades range from $8.50-$12.00 per square foot for 1.5-inch thermal finish material

- Your select grade specifications should expect $11.00-$16.00 per square foot depending on thickness and finish requirements

- Natural cleft finishes provide 15-25% cost savings versus thermal finishes but require accepting greater thickness variation

- You should plan for 8-12% waste factors when working with irregular cleft material versus 5-7% for dimensional thermal

The imported bluestone Arizona yards distribute comes predominantly from northeastern Pennsylvania quarries near Susquehanna County, where consistent blue-gray coloring originates. You’ll occasionally encounter north-central Pennsylvania material with more pronounced brown and lilac tones, creating aesthetic differences that surprise clients expecting traditional blue-gray presentation. Always verify quarry source before committing to large orders.

Thermal Performance Specifications

Pennsylvania bluestone Arizona stone yard installations face surface temperatures reaching 135-155°F during peak summer conditions with direct solar exposure. The material’s thermal conductivity of 1.6-2.1 BTU per hour per square foot creates slower heat transfer than granite or quartzite alternatives, but you’re still specifying stone that becomes uncomfortably hot for bare feet between 11 AM and 6 PM from May through September.

Your thermal mass calculations need to account for the 4-6 hour lag between air temperature peaks and surface temperature peaks. This characteristic means that bluestone surfaces remain warm well into evening hours, affecting outdoor living space usability. You’ll find that shaded installations or areas with afternoon shade patterns perform significantly better for residential comfort than full-exposure applications.

- You should specify light-colored full-range material when surface temperature control matters, as lighter tones reflect 15-22% more solar radiation

- Your irrigation system design must prevent direct overspray onto hot stone surfaces, as thermal shock can induce surface spalling over 8-12 year periods

- You’ll need expansion joints every 12-15 feet in Arizona applications, tighter than the 15-20 feet typical in moderate climates

- Consider specifying premium bluestone Arizona yards provide with verified low-absorption ratings below 1.5% for maximum thermal cycling durability

What catches most specifiers off-guard is how thermal expansion affects joint sand retention in desert installations. The material expands and contracts through 0.020-0.030 inch cycles across typical 15-foot field dimensions, creating joint movement that accelerates sand migration. You need polymeric sand systems rated for high-movement applications, not standard residential products that fail within 18-24 months under Arizona conditions.

Installation Considerations for Desert Climate

When you plan Pennsylvania bluestone Arizona stone yard installations, you’re adapting northeastern installation practices to southwestern conditions that change the rules. Substrate moisture content requirements shift from the 4-6% maximum typical in humid climates to 2-3% maximum in Arizona, where dry soil conditions create different base stability concerns. You need compacted aggregate bases achieving 95-98% modified Proctor density to prevent settlement under thermal cycling stress.

Your installation timing becomes critical in desert markets. Summer installations between June and August expose setting materials and workers to conditions that compromise installation quality. Mortar sets too quickly, polymeric sand activators evaporate before proper bonding occurs, and material handling becomes hazardous with surface temperatures exceeding 140°F. You should schedule installations during October through April windows when you’ll achieve optimal material performance and worker safety.

The Arizona stone yard bluestone import you’re installing requires modified joint spacing compared to manufacturer recommendations developed for moderate climates. Standard 3/16-inch joints prove insufficient for thermal expansion in desert applications. You need 1/4-inch minimum joints for dimensional material and 3/8-inch joints for irregular cleft installations to accommodate movement without edge spalling or lippage development.

- You’ll want to verify base aggregate contains minimal fines content, as desert dust infiltration creates unstable conditions over 5-8 year periods

- Your edge restraint specifications must account for 40-60% greater lateral pressure from thermal expansion compared to moderate climate installations

- You should require 72-hour minimum cure times for setting beds before allowing foot traffic, extended from typical 48-hour recommendations

- Consider warehouse staging for material acclimation when truck deliveries arrive with stone at significantly different temperatures than installation site conditions

Cost Analysis and Value Comparison

Pennsylvania bluestone Arizona stone yard pricing positions the material in the premium segment, competing against local flagstone at $4.50-$7.00 per square foot and travertine at $6.50-$11.00 per square foot. You’re paying 30-45% premiums for imported bluestone, which requires justification through performance advantages and aesthetic preferences that clients value enough to support higher budgets.

Your total installed cost calculations need to include freight impacts, storage requirements, and specialized installation labor that PA bluestone stone yard Arizona projects demand. When you factor $3.50-$6.50 per square foot installation labor, edge details, base preparation, and sealing requirements, total project costs reach $14.00-$24.00 per square foot. This positions imported bluestone Arizona yards supply as specification-grade material for high-value residential and commercial applications.

The value proposition centers on longevity expectations that exceed local alternatives. You should communicate 30-40 year service life projections for properly installed bluestone versus 15-25 years for local flagstone and 20-30 years for travertine in similar applications. The material’s superior density and lower porosity translate to better stain resistance, reduced maintenance requirements, and sustained appearance that justifies initial cost premiums for clients focused on lifecycle value.

- You’ll find that premium bluestone Arizona yards maintain delivers 8-12% lower callback rates for installation issues compared to economy-grade alternatives

- Your maintenance cost projections should account for biennial resealing requirements at $0.85-$1.40 per square foot

- You can specify 15-20 year joint sand replacement intervals versus 8-12 years typical with softer stone options

- Consider lifecycle cost analysis showing 18-22% lower total ownership costs over 25-year evaluation periods despite higher initial investment

Surface Finish Options and Performance

Natural cleft Pennsylvania bluestone from Arizona stone yards provides the most economical finish option, featuring textured surfaces with 1/4-inch to 3/4-inch thickness variation across individual pieces. When you specify natural cleft, you’re accepting rustic character and irregular joint lines that create informal aesthetics. The finish delivers excellent slip resistance with DCOF ratings of 0.60-0.68 dry and 0.48-0.55 wet, making it suitable for pool decks and high-traffic areas where traction matters.

Thermal finish bluestone offers dimensional consistency with ±1/8-inch thickness tolerance and lightly textured surfaces created by torch-flame treatment. You’ll specify thermal when you need precise joint alignment, contemporary aesthetics, and easier installation that reduces labor costs by 15-20% compared to natural cleft. The finish maintains good slip resistance at DCOF 0.52-0.60 dry and 0.42-0.50 wet, though you need enhanced traction treatments for pool surrounds and other wet-use applications.

- You should understand that honed finishes, while aesthetically appealing, reduce slip resistance to DCOF 0.38-0.45 and require aggressive anti-slip treatments for Arizona pool applications

- Your thermal finish specifications need to address torch treatment depth, as shallow treatments wear through in 8-12 years under high foot traffic

- You’ll observe that natural cleft surfaces hide minor staining and wear patterns better than smooth finishes, reducing maintenance visibility

- Consider specifying sawn-bottom natural cleft material from premium bluestone Arizona yards for optimal installation ease while maintaining rustic top surface character

The surface finish you select affects heat absorption characteristics more than most specifiers anticipate. Thermal and honed finishes create smoother surfaces that reach 8-12°F higher temperatures than natural cleft under identical conditions. The textured cleft surface increases effective surface area and creates micro-shadows that reduce solar absorption, making natural cleft the preferred specification for bare-foot contact areas in Arizona applications.

Sealing and Maintenance Requirements

Pennsylvania bluestone Arizona stone yard installations require penetrating sealers that protect against the unique staining challenges desert environments present. You’re dealing with mineral-rich irrigation water, dust infiltration, and organic debris that create staining patterns different from humid climate concerns. Your sealer specifications should target products providing 3-5 year protection cycles while maintaining natural stone appearance and adequate surface breathability.

The material’s low porosity means you’re not sealing to prevent water absorption as much as protecting against surface contamination and UV-induced color fading. Arizona’s intense solar radiation accelerates sealer breakdown, requiring you to recommend maintenance reapplication every 24-30 months for optimal protection. You’ll find that solvent-based penetrating sealers outperform water-based alternatives in desert climates, providing 30-40% longer effective protection periods.

- You need to specify pH-neutral cleaners for routine maintenance, as alkaline products accelerate sealer degradation in low-humidity environments

- Your maintenance protocols should include quarterly sweeping to remove dust and debris that abrade sealed surfaces

- You should recommend avoiding pressure washing above 1,200 PSI, as high pressure damages both sealer protection and can induce surface spalling on thermally-stressed stone

- Consider specifying color-enhancing sealers for full-color material when clients prefer more pronounced color depth and contrast

Joint sand maintenance becomes more critical in Arizona installations than moderate climate applications. The imported bluestone Arizona yards stock requires polymeric sand systems that withstand thermal cycling without losing flexibility. You’ll need to communicate that joint sand represents a maintenance item requiring inspection every 18-24 months and top-off applications when sand levels drop below 85% of joint depth.

Common Specification Mistakes

When you work with PA bluestone stone yard Arizona suppliers, you’ll want to avoid the specification errors that create project problems months or years after installation. The most frequent mistake involves failing to address thermal expansion adequately in contract documents. Standard northeastern specifications calling for 3/16-inch joints and 20-foot expansion joint spacing prove insufficient for Arizona thermal conditions, leading to edge spalling and lippage development within 2-3 years.

Your specifications need to explicitly address color variation acceptance criteria beyond generic “natural variation” language. Pennsylvania bluestone exhibits wider color ranges than many specifiers anticipate, particularly when Arizona yards blend inventory from multiple quarry sources. You should include physical samples approved by clients as contract standards, acknowledging that exact matching is unrealistic but establishing acceptable variation parameters.

- You’ll encounter problems when specifications fail to address substrate moisture testing protocols specific to desert soil conditions

- Your edge detail specifications must account for thermal expansion pressure that standard restraint systems can’t contain

- You should explicitly prohibit summer installations or require enhanced protection protocols that most contractors won’t implement without contractual obligation

- Consider specifying minimum acclimation periods when material arrives from warehouse storage at temperatures differing significantly from installation site conditions

Another common error involves underestimating the skill level required for quality Pennsylvania bluestone installation in desert climates. You can’t assume that contractors experienced with local flagstone possess the knowledge to properly install imported bluestone with its tighter tolerances and different handling characteristics. Your specifications should require installer qualifications demonstrating experience with dimensional stone in thermal-expansion-prone environments.

Competitive Alternatives Comparison

When you evaluate Pennsylvania bluestone Arizona stone yard options against alternatives, you’re comparing imported premium material against several locally-available choices that offer different value propositions. Arizona flagstone provides the most economical alternative at $4.50-$7.00 per square foot, delivering informal aesthetics and acceptable durability for residential applications. The material lacks bluestone’s density and color consistency, showing more pronounced weathering and staining over 15-20 year service periods.

Travertine represents mid-range competition at $6.50-$11.00 per square foot, offering light colors that reflect more solar radiation than bluestone. You’ll specify travertine when surface temperature control outweighs the density and durability advantages Pennsylvania bluestone provides. The material’s higher porosity requires more intensive sealing and maintenance protocols, and its softer composition shows wear patterns more readily in high-traffic applications.

Granite and quartzite alternatives from premium bluestone Arizona yards compete at similar price points of $9.00-$18.00 per square foot but deliver different aesthetic and performance characteristics. These igneous and metamorphic options provide superior hardness and even lower absorption rates, but their crystalline structures create higher thermal conductivity and more intense surface temperatures that limit comfort in direct-sun applications.

- You should evaluate local sandstone options offering natural earth tones at $5.50-$9.00 per square foot when budget constraints limit imported stone consideration

- Your specifications might consider limestone alternatives at $7.00-$12.00 per square foot for projects prioritizing light colors and lower surface temperatures

- You’ll find that manufactured concrete pavers at $4.00-$8.00 per square foot provide dimensional consistency but lack the natural character and premium positioning natural stone delivers

Citadel Stone — Premium stone yard Arizona Expertise: Hypothetical Project Guidance

When you consider Citadel Stone’s stone yard Arizona materials for your projects, you’re evaluating premium Pennsylvania bluestone specifically selected for southwestern climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low-desert heat to high-country freeze-thaw conditions. This section outlines how you would approach specification decisions for six representative cities, demonstrating the regional adaptation strategies your projects would require.

The following city-specific guidance represents recommended approaches for hypothetical projects, not completed installations. You’ll find climate-specific considerations, material selection recommendations, and installation factors that would influence your specification decisions in each regional market. Your actual projects would require site-specific engineering and detailed performance evaluation beyond these general guidelines.

Phoenix Heat Management

In Phoenix applications, you would confront extreme heat that drives surface temperatures to 145-155°F during peak summer exposure. Your Pennsylvania bluestone Arizona stone yard selections would prioritize lighter-colored full-range material reflecting maximum solar radiation. You’d specify 1/4-inch minimum joint spacing and expansion joints every 12 feet to accommodate thermal cycling that exceeds 60°F daily swings during summer months. The project would require fall or winter installation windows to ensure proper material setting and sealer curing under optimal temperature conditions.

Tucson Performance Factors

Your Tucson specifications would address similar heat challenges to Phoenix while accounting for slightly higher elevation and different soil conditions. You’d recommend Arizona stone yard bluestone import material with verified low absorption rates below 1.5% to handle monsoon moisture exposure followed by rapid drying cycles. The installation would require enhanced base preparation addressing caliche layers common in Tucson soils, potentially adding 15-20% to base preparation costs compared to standard specifications. You would specify polymeric joint sand systems rated for high-UV exposure and thermal cycling.

Scottsdale Luxury Applications

Scottsdale’s high-value residential market would call for premium select-grade material from PA bluestone stone yard Arizona suppliers, emphasizing color consistency and refined aesthetics. You’d recommend thermal finish for contemporary installations or premium natural cleft with tight thickness tolerances for transitional design applications. Your specifications would include color-enhancing sealers to maximize visual impact and detailed edge profiles that justify premium material investment. The project would benefit from warehouse staging to ensure sufficient single-lot material availability for color-matched installations exceeding 3,000 square feet.

Flagstaff Freeze-Thaw Durability

At Flagstaff’s 7,000-foot elevation, your focus would shift to freeze-thaw performance rather than heat management. Pennsylvania bluestone’s low porosity and high density make it excellent for this application, but you’d specify material with absorption rates below 1.2% for maximum freeze-thaw resistance. Your installation would require proper drainage design preventing standing water and ice accumulation in joints. You’d recommend 3/8-inch joints with flexible polymeric sand systems maintaining elasticity through winter temperature cycling. The imported bluestone Arizona yards deliver would outperform local alternatives in this demanding freeze-thaw environment.

Sedona Aesthetic Integration

Sedona applications would require careful color selection ensuring Pennsylvania bluestone complements rather than conflicts with the area’s distinctive red rock landscape. You’d recommend full-color grades incorporating warm rust and brown tones that harmonize with natural surroundings. Your specifications would address the tourist-destination foot traffic these installations typically experience, requiring premium-grade material with proven high-traffic durability. The project would benefit from natural cleft finishes providing slip resistance for outdoor hospitality applications while delivering rustic character appropriate to Sedona’s aesthetic.

Mesa Value Engineering

Mesa’s diverse market would create opportunities for value-engineered Pennsylvania bluestone Arizona stone yard applications balancing premium material quality with competitive pricing pressures. You’d recommend strategic bluestone use in primary entertainment areas while specifying complementary local materials for secondary spaces. Your specifications would optimize thickness selection, potentially using 1.5-inch thermal material instead of 2-inch to reduce costs while maintaining adequate performance. The approach would leverage premium bluestone Arizona yards stock for visible, high-impact areas while managing overall project budgets through selective material deployment.

Procurement Timeline and Planning

When you plan Pennsylvania bluestone Arizona stone yard procurement, you’re managing lead times that extend well beyond local material sourcing. Standard inventory replenishment from Pennsylvania quarries requires 3-4 weeks transit time plus warehouse processing, meaning you need to initiate material orders 6-8 weeks before scheduled installation dates. Special orders for specific grades, sizes, or finishes extend lead times to 10-14 weeks as yards coordinate with quarry production schedules.

Your project timeline must account for seasonal demand fluctuations that affect availability and pricing. Spring and fall construction peaks strain Arizona stone yard bluestone import inventory, sometimes creating temporary shortages that delay projects or force specification changes. You’ll encounter the best availability and pricing during summer and winter slow periods when yards maintain higher inventory ratios and offer better terms to maintain cash flow.

- You should confirm material availability before finalizing specifications, particularly for projects requiring 3,000+ square feet of consistent-grade material

- Your procurement strategy needs backup suppliers identified when primary sources can’t meet project timelines or quantity requirements

- You’ll want to coordinate truck delivery scheduling around job site access constraints, particularly for residential projects in established neighborhoods

- Consider specifying material delivery 1-2 weeks before installation to allow acclimation and staging without excessive on-site storage duration

The reality is that imported bluestone Arizona yards distribute comes from limited quarry sources with finite production capacity. You can’t assume unlimited availability or rapid fulfillment the way you might with manufactured products. Your professional practice requires maintaining relationships with multiple suppliers and planning material procurement as early in the design process as practical to avoid schedule disruptions.

Quality Verification and Acceptance

Pennsylvania bluestone Arizona stone yard deliveries require systematic quality verification before you accept material and authorize installation. You need protocols checking for color consistency against approved samples, thickness tolerance verification, and damage assessment from cross-country shipping. Standard acceptance criteria allow 5-8% of material showing minor edge chips or surface imperfections that don’t compromise structural integrity or visible aesthetics.

Your verification process should include random sampling of crates or pallets, as material quality can vary throughout truck loads. You’ll inspect for delamination issues, checking that stone doesn’t separate along bedding planes when you handle pieces. PA bluestone stone yard Arizona suppliers occasionally receive material with incipient delamination that becomes apparent only during installation, creating costly delays and material replacement requirements.

- You should verify that thermal finish depth meets specifications, typically requiring 1/8-inch minimum torch penetration for adequate durability

- Your thickness checks need to confirm dimensional material stays within ±1/8-inch tolerance specified for thermal products

- You’ll want to assess color distribution across the delivery, rejecting loads showing greater variation than approved sample ranges

- Consider requiring pre-installation mockups for projects exceeding $50,000 material value to verify aesthetics before full installation proceeds

Professional practice includes documenting acceptance conditions with photographs and written reports that establish baseline quality standards. This protects you when disputes arise months later about color variation, thickness inconsistencies, or other quality factors that may not become apparent until installation is substantially complete. The imported bluestone Arizona yards provide should meet documented specifications, and you need verification records proving that standard was achieved.

Final Considerations

Pennsylvania bluestone from Arizona stone yards represents a premium specification choice that delivers distinctive aesthetics and proven durability when you apply appropriate regional adaptation strategies. Your success with this imported material depends on understanding its thermal performance characteristics, accounting for logistics that extend lead times and affect pricing, and implementing installation protocols modified for desert climate conditions. The material’s density and low porosity provide advantages over many local alternatives, but you need to justify cost premiums through lifecycle value analysis that clients find compelling.

When you specify premium bluestone Arizona yards stock, you’re making decisions that affect project performance for 30-40 years. The initial specification phase determines whether installations meet client expectations or create maintenance burdens and premature deterioration. Your professional expertise shows in the details — joint spacing adapted for thermal expansion, sealer selection appropriate for UV exposure, and color acceptance criteria that prevent disputes during installation. For additional technical guidance on surface preparation and material handling, review Comparative analysis of natural cleft versus thermal bluestone finishes before finalizing your project specifications. Barbecue surround construction specifies Citadel Stone’s heat-tested stone yard masonry in Arizona materials.