When you evaluate paving stones suppliers Arizona for your commercial or residential project, you’re navigating a complex landscape of material sourcing, quality verification, and regional performance requirements. The natural stone dealers Phoenix metro and throughout Arizona must demonstrate expertise in desert climate specifications, inventory management, and technical support that extends beyond simple product availability. Your supplier selection directly impacts project timelines, installation success, and long-term performance outcomes.

Finding reliable paving stones suppliers Arizona involves more than comparing price lists. You need partners who understand thermal expansion coefficients in 120°F heat, who maintain warehouse stock during peak construction seasons, and who can explain why certain limestone varieties outperform others in alkaline soil conditions. The difference between adequate suppliers and exceptional stone paving suppliers directory entries becomes apparent when you encounter field challenges that require immediate technical guidance.

Material Sourcing and Verification Standards

You should establish verification protocols that examine material origins, quarry certifications, and processing methods before committing to paving stones suppliers Arizona. The natural stone dealers Phoenix professionals you work with must provide documentation confirming ASTM compliance for compressive strength, absorption rates, and dimensional tolerances. Your due diligence protects against substandard materials that appear acceptable initially but fail within 5-7 years due to inherent structural deficiencies.

Premium paving stones Arizona suppliers maintain relationships with quarries that implement quality control at extraction points, not just at distribution facilities. You’ll find that suppliers offering multiple stone varieties from diverse geographic sources provide better project flexibility than single-quarry operations. When you request material certifications, expect comprehensive test data covering freeze-thaw durability (even in southern Arizona, elevation changes create freeze exposure), slip resistance coefficients, and porosity measurements under standardized conditions.

- You need compressive strength documentation exceeding 8,000 PSI for vehicular applications

- Your absorption rate specifications should confirm values below 3% for exterior installations

- You should verify dimensional tolerance compliance within ±3mm for precision layouts

- Slip resistance ratings must meet or exceed 0.42 DCOF for pool decks and wet areas

- You’ll require chemical resistance data for installations near saltwater pools or fertilized landscapes

The stone supplier product range available through established paving stones suppliers Arizona extends beyond basic flagstone and pavers. You can source specialized materials including thermal-modified surfaces that remain 15-20°F cooler than standard finishes, textured profiles engineered for specific traction requirements, and calibrated thickness options that simplify installation over existing concrete substrates. Your material selection conversations should address these performance-enhanced options when project conditions demand solutions beyond conventional products.

Regional Climate Performance Factors

Arizona’s climate zones create distinct performance requirements that you must address through informed supplier selection. When you work with paving stones suppliers Arizona who understand regional variations, you gain access to climate-specific recommendations that prevent costly specification errors. The temperature differential between Yuma summer surfaces (reaching 165°F) and Flagstaff winter conditions (dropping to -15°F) demands materials with proven thermal stability across 180-degree ranges.

You should prioritize natural stone dealers Phoenix operations that can explain thermal mass behavior and its impact on your specific installation. Desert installations benefit from materials with high thermal mass that moderate temperature swings, but you need to understand the 4-6 hour lag time between peak air temperature and peak surface temperature. This lag affects everything from installation scheduling to landscape irrigation timing, as surface heat radiation continues hours after sunset.

The alkaline soil conditions prevalent across Arizona create unique challenges that premium paving stones Arizona suppliers address through material selection guidance. You’ll encounter soil pH levels ranging from 7.8 to 9.2 in most metropolitan areas, which accelerates efflorescence in certain limestone varieties. Your supplier should identify calcium carbonate content levels and recommend sealing protocols that mitigate salt migration without trapping subsurface moisture. When you specify materials for projects in areas with caliche layers, your base preparation requirements change significantly—a detail that experienced stone paving suppliers directory professionals recognize immediately.

Inventory Management and Lead Times

Your project timeline depends heavily on warehouse inventory practices maintained by paving stones suppliers Arizona. When you request quotes, you should simultaneously verify current stock levels, replenishment schedules, and truck delivery lead times to job sites across the state. Suppliers maintaining local inventory provide 3-5 day delivery windows, while those relying on out-of-state warehouses may require 3-4 weeks—a difference that can derail construction schedules during peak seasons.

The stone supplier product range you can access immediately versus materials requiring special orders affects design flexibility and budget predictability. You’ll find that natural stone dealers Phoenix facilities with 50,000+ square feet of covered warehouse space offer better selection consistency than smaller operations dependent on just-in-time deliveries. When you plan large commercial projects requiring phased installations over 6-12 months, you need suppliers who can reserve inventory lots to ensure color and texture consistency across multiple shipments.

- You should confirm warehouse stock before finalizing specifications for projects requiring 10,000+ square feet

- Your delivery coordination must account for truck access limitations at urban job sites

- You need suppliers who provide covered storage protecting materials from weather exposure before installation

- You’ll want verification that reserved inventory lots come from matching quarry production runs

- Your contingency planning should include backup suppliers for critical-path timeline protection

Understanding regional distribution logistics helps you anticipate when paving stones suppliers Arizona can realistically deliver to remote locations. Truck transportation from Phoenix or Tucson warehouses to destinations like Page or Kingman adds 2-3 days to standard delivery windows, plus fuel surcharges that impact per-square-foot costs by $0.40-$0.75. When you coordinate deliveries to sites with restricted access hours or HOA delivery limitations, you must communicate these constraints during initial supplier discussions to avoid delays that cascade through subsequent trade schedules.

Technical Support and Installation Guidance

The value proposition offered by premium paving stones Arizona suppliers extends beyond material sales to comprehensive technical support that addresses field installation challenges. You need access to specification assistance that considers substrate conditions, joint spacing calculations for thermal expansion, and base preparation requirements specific to regional soil compositions. When you encounter unexpected field conditions—clay layers at depths not revealed by initial soil reports, for example—you require supplier expertise that provides immediate alternative solutions rather than generic troubleshooting advice.

Your installation crews benefit when natural stone dealers Phoenix operations provide detailed layout guidance addressing pattern variations, edge detail transitions, and cut stone integration. The difference between 92% and 97% specification compliance often traces directly to pre-installation planning support that anticipates dimensional tolerance stacking effects. You should expect suppliers to review site preparation specifications, recommend bedding material gradations, and identify potential drainage issues before crews mobilize to job sites.

When you specify materials from stone paving suppliers directory sources offering ongoing technical support, you gain partners who assist with long-term maintenance planning and warranty claim resolution. Installation defects versus material defects require expert assessment—efflorescence appearing 18 months post-installation, for instance, may result from improper base preparation rather than inherent material flaws. You need suppliers who provide objective analysis rather than automatically deflecting responsibility, as this approach resolves issues efficiently and preserves professional relationships across multiple projects.

Product Range and Specialization

Evaluating the stone supplier product range available through various paving stones suppliers Arizona reveals specialization patterns that inform your sourcing strategy. Some suppliers focus exclusively on regional materials—Arizona flagstone, Sedona sandstone, local limestone varieties—while others import specialty products from Oklahoma, Pennsylvania, or international quarries. Your project requirements determine whether you prioritize local material expertise or comprehensive selection spanning domestic and imported options.

You’ll discover that premium paving stones Arizona suppliers offering specialized products address niche applications conventional suppliers cannot serve. Thermal-modified surfaces that remain touchable during peak heat, precision-calibrated pavers for pedestal installations, and custom edge profiles for pool coping represent value-added products requiring specific processing capabilities. When you need these specialized solutions, you should work with suppliers who manufacture or process materials in-house rather than brokers who simply resell commodity products.

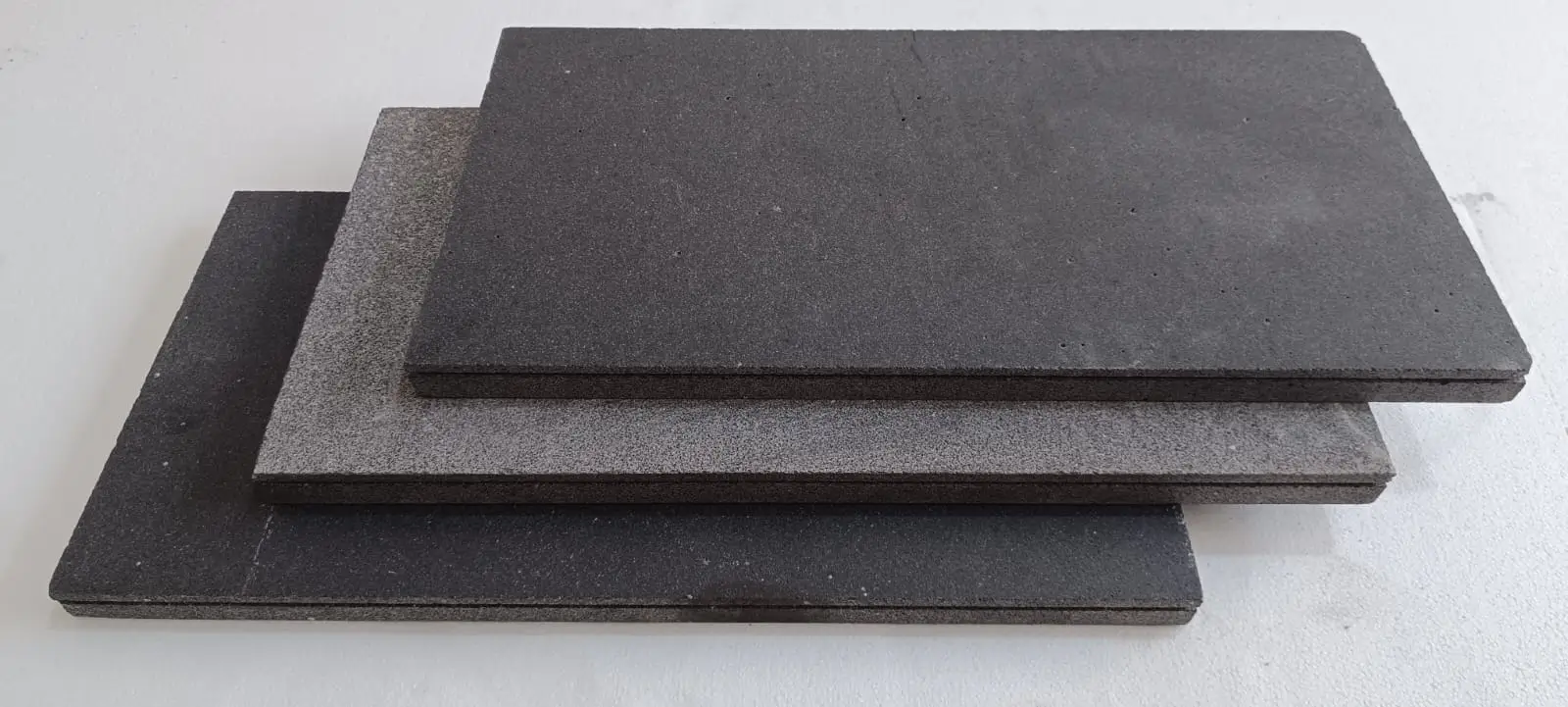

- You can source materials in thickness ranges from 1.25 inches for pedestrian areas to 3 inches for vehicular applications

- Your finish options include thermal, flamed, honed, sandblasted, and natural cleft surfaces

- You should evaluate suppliers offering custom sizing that reduces field cutting requirements

- You need access to matching coping, step treads, and wall cap profiles for complete project integration

- Your design flexibility improves when suppliers stock complementary materials for borders and accent features

The natural stone dealers Phoenix market includes specialists focusing on specific material categories—travertine experts, bluestone specialists, limestone-focused suppliers—whose depth of knowledge in their categories exceeds generalist operations. When you specify a project using predominantly one material type, these specialists often provide better technical guidance, superior material grading, and more consistent quality control than broad-range suppliers. However, you’ll need relationships with multiple specialists to serve diverse project portfolios, which creates coordination complexity that generalist suppliers eliminate through comprehensive inventories.

Pricing Structure and Value Analysis

Your cost analysis when comparing paving stones suppliers Arizona must extend beyond per-square-foot pricing to encompass total installed cost factors. Suppliers offering materials at $4.50 per square foot may actually cost more than competitors pricing at $5.25 once you account for waste factors, cutting requirements, and installation labor variations. You should request detailed breakdowns separating material costs, delivery charges, and any minimum order requirements that affect small or phased projects.

When you evaluate premium paving stones Arizona options, you’re assessing value propositions based on performance longevity and maintenance requirements rather than initial acquisition cost alone. Materials priced 30-40% above basic alternatives often justify premiums through reduced sealing frequency, superior stain resistance, and 25-year performance expectations versus 15-year lifespans. Your lifecycle cost calculations should incorporate these factors, especially for commercial installations where replacement costs include business disruption expenses exceeding material and labor charges.

The stone supplier product range pricing reflects quality grades within material categories that you must understand to make informed selections. You’ll encounter “select” grade materials with minimal color variation, “standard” grades showing natural diversity, and “commercial” grades optimized for cost efficiency. Natural stone dealers Phoenix professionals should explain these distinctions clearly, as grade selection dramatically impacts aesthetic outcomes and installed appearance consistency. When you specify select-grade materials at standard-grade budgets, you create value engineering conflicts that delay projects and compromise design intent.

Quality Control and Inspection Protocols

You should implement receiving inspection procedures that verify materials delivered by paving stones suppliers Arizona match specification requirements before installation begins. Quality control protocols must address dimensional accuracy, surface finish consistency, color range compliance, and defect identification. Your inspection process protects against disputes by documenting material conditions at delivery, establishing clear acceptance criteria that both parties acknowledge.

Random sampling methods provide practical quality verification without inspecting every piece in large shipments. You can examine 5-10% of delivered materials, focusing on pieces from different crate locations to detect batch variations that occasional spot-checks might miss. When you identify defects exceeding specified tolerances—chips beyond 10mm, thickness variations exceeding ±3mm, or color deviations outside approved ranges—you must document issues immediately and coordinate returns or replacements before installation crews mobilize. For guidance on related specifications, see Arizona cobble paving for detailed technical requirements.

- You need clear defect definitions established during specification development

- Your acceptance criteria should address natural stone characteristics versus manufacturing defects

- You must document material conditions photographically upon delivery

- You should establish protocols for handling borderline cases requiring expert assessment

- Your contracts must specify responsibility allocation for rejected materials and associated delays

Working with premium paving stones Arizona suppliers who implement upstream quality control at quarries reduces field rejection rates from 8-12% to 2-3%. You benefit when suppliers pre-inspect materials before warehouse stocking, removing obviously defective pieces that would otherwise reach job sites. This quality assurance approach streamlines your receiving inspection processes and minimizes installation delays caused by insufficient acceptable materials.

Sustainability and Sourcing Ethics

Your supplier selection criteria should incorporate sustainability factors that address quarry practices, transportation efficiency, and environmental impact documentation. When you evaluate paving stones suppliers Arizona, you can request information about quarry reclamation plans, water recycling systems, and habitat protection measures implemented at extraction sites. Suppliers partnering with quarries holding environmental certifications provide documentation supporting LEED credit applications and corporate sustainability reporting requirements.

Transportation distance creates significant environmental and cost implications that you should consider during material selection. Regional natural stone dealers Phoenix sources provide materials extracted within 500 miles, reducing fuel consumption and carbon emissions compared to imported alternatives traveling 2,000+ miles. Your project sustainability calculations should quantify these differences, as transportation impacts often exceed the embodied energy in stone extraction and processing combined.

The stone supplier product range offered by ethically-focused suppliers includes materials from quarries maintaining fair labor practices and community investment programs. You can request third-party certification documentation verifying compliance with workplace safety standards and fair wage requirements. When you prioritize these verified suppliers, you support improved industry practices while mitigating reputational risks associated with materials sourced from operations with questionable labor conditions.

Warranty and Support Structures

Understanding warranty coverage provided by paving stones suppliers Arizona helps you manage long-term project risk and client expectations. You should distinguish between material warranties covering inherent defects and installation warranties addressing workmanship issues, as supplier responsibilities typically extend only to material performance. Standard warranties cover delamination, structural failure, and manufacturing defects for periods ranging from 1-5 years, though natural stone characteristics like color variation and weathering remain outside warranty scope.

Your warranty claim procedures require documentation demonstrating proper installation methods, appropriate maintenance practices, and specific defect characteristics qualifying for coverage. Suppliers evaluate claims by examining installation photos, maintenance records, and field conditions to determine whether observed problems result from material defects versus external factors. When you maintain comprehensive project documentation—installation specifications, weather conditions during installation, maintenance performed—you support valid claims while avoiding disputes over responsibility allocation.

- You need written warranty terms defining covered defects and exclusions before project commencement

- Your documentation should include pre-installation material inspections and acceptance records

- You must follow specified installation guidelines to maintain warranty validity

- You should understand claims procedures and response timelines included in warranty terms

- Your contracts must clarify whether suppliers provide replacement materials only or cover installation labor costs

Working with premium paving stones Arizona suppliers offering extended support beyond minimum warranty periods provides long-term value protection. These suppliers maintain technical support staff who address performance questions years after installation, provide maintenance guidance preventing premature deterioration, and offer replacement materials from reserved inventory lots when repairs require color matching. When you establish relationships with these service-oriented suppliers, you gain partners who support project success throughout material lifecycles rather than abandoning clients after transactions complete.

Supplier Qualification Process

You should develop systematic qualification procedures evaluating paving stones suppliers Arizona across multiple performance dimensions before awarding contracts. Your assessment criteria must address financial stability, inventory capacity, delivery reliability, technical expertise, and quality consistency. This due diligence process identifies suppliers capable of supporting projects from specification through warranty periods, eliminating vendors who appear competitive initially but lack infrastructure for reliable long-term performance.

Financial stability verification protects you against supplier failures that strand projects mid-installation with no material access. You can request credit references, review business longevity histories, and confirm warehouse ownership versus leased facilities indicating operational permanence. Natural stone dealers Phoenix operations with 15+ years of continuous business demonstrate market viability and customer satisfaction that new entrants cannot match. When you work with established suppliers, you gain confidence that warranty commitments remain valid and supported resources exist for addressing future issues.

Technical expertise assessment should include conversations evaluating supplier knowledge about regional installation challenges, material performance characteristics, and specification requirements. You’ll quickly determine whether sales representatives understand thermal expansion calculations, base preparation requirements for expansive soils, and sealing protocol variations based on material porosity. The stone supplier product range expertise demonstrated through these conversations reveals whether suppliers function as knowledgeable advisors or simple order-takers who cannot support complex projects.

Best Paving Slabs in Arizona: Citadel Stone Regional Specifications

When you evaluate Citadel Stone’s paving slabs for your Arizona installation, you’re considering premium materials engineered specifically for extreme desert climate performance. At Citadel Stone, we provide technical guidance for hypothetical applications across Arizona’s diverse climate zones, from low-desert heat extremes to high-elevation freeze-thaw conditions. This section outlines how you would approach specification decisions for six representative cities, addressing the unique performance requirements you’ll encounter in each location.

Your material selection process requires understanding how thermal cycling, UV exposure intensity, and alkaline soil chemistry affect long-term paving slab performance. You would need to account for surface temperatures reaching 165°F in summer months while simultaneously planning for winter conditions in elevated regions where freeze-thaw cycles occur 30-50 times annually. The paving slabs you specify must demonstrate thermal stability across these extremes without delamination, spalling, or structural degradation. Professional installations typically achieve optimal performance when you select materials with compressive strength exceeding 9,500 PSI and absorption rates maintained below 2.8%.

Phoenix Heat Management

In Phoenix, you’ll encounter the most extreme sustained heat conditions in Arizona, with summer surface temperatures regularly exceeding 155°F on conventional paving materials. Your specification approach would emphasize thermal-reflective surface treatments that reduce heat absorption by 15-20°F compared to standard finishes. You should account for the urban heat island effect amplifying already extreme temperatures, creating conditions where material thermal mass properties become critical comfort factors. The paving slabs you would recommend for Phoenix applications demonstrate proven performance in temperatures sustained above 110°F for 120+ days annually, with thermal expansion coefficients accommodated through joint spacing calculations increased by 18% compared to temperate climate standards.

Tucson Monsoon Considerations

Your Tucson specifications would address intense monsoon rainfall patterns delivering 2-3 inches within 60-90 minute periods, creating flash drainage requirements that standard installations often fail to accommodate. You need paving slabs with surface texturing that maintains traction when saturated while subsurface drainage systems handle water volumes equivalent to 6-month accumulations in other climates. The alkaline soil conditions in Tucson amplify efflorescence potential, requiring you to specify sealing protocols within 60 days of installation to prevent salt migration that becomes visible 12-18 months later. You would recommend materials demonstrating chemical resistance to pH levels reaching 8.8, which characterizes typical Tucson soil chemistry throughout residential development areas.

Scottsdale Luxury Standards

When you specify paving slabs for Scottsdale projects, you’re addressing expectations for premium aesthetics combined with uncompromising performance standards. Your material selection would emphasize consistent color grading within tight tolerance ranges, surface finish uniformity across large installations, and dimensional precision supporting pattern layouts with minimal grout joint visibility. You should recommend select-grade materials where color variation remains within 10% luminosity ranges and thickness tolerances stay within ±2mm across entire shipments. The Scottsdale market demands you consider long-term appearance retention, requiring materials that resist UV fading and maintain original color characteristics for 15+ years under intense solar exposure exceeding 4,000 hours annually.

Flagstaff Freeze Durability

Your Flagstaff specifications would prioritize freeze-thaw durability above all other performance factors, as this high-elevation location experiences 140+ freeze-thaw cycles annually. You need paving slabs with absorption rates maintained below 2.5% and pore structures that resist ice crystal formation damage during repeated freezing. The materials you would recommend for Flagstaff demonstrate ASTM C1026 compliance verified through 300+ freeze-thaw cycle testing without structural degradation. You should specify installation methods incorporating base drainage that prevents subsurface ice lens formation, which creates heaving forces exceeding material design loads. At Citadel Stone, we recommend materials with proven performance in climates where winter temperatures drop below 0°F for extended periods, creating conditions where inferior products fail within 5-7 years.

Sedona Aesthetic Integration

In Sedona, you would approach paving slab specification with emphasis on natural color harmonization with the region’s distinctive red rock formations. Your material selection process would identify limestone and sandstone varieties exhibiting earth-tone palettes ranging from buff to terracotta hues that complement rather than compete with the surrounding landscape. You need to consider that Sedona’s high-profile residential market demands materials demonstrating both artistic merit and technical performance across temperature ranges spanning 15°F winter lows to 100°F summer highs. The paving slabs you specify should maintain slip resistance ratings exceeding 0.50 DCOF across varied surface moisture conditions, as Sedona’s tourism-focused properties require liability protection for high foot traffic volumes across residential and light commercial applications.

Yuma Extreme Conditions

Your Yuma specifications would address the most challenging combination of extreme heat, minimal precipitation, and intense UV exposure found anywhere in Arizona. You should recommend paving slabs engineered for surface temperatures reaching 170°F, which represents conditions where conventional materials experience accelerated aging and premature deterioration. The materials you would specify require UV stabilization treatments preventing color degradation under solar radiation levels that accumulate 4,200+ hours annually at intensities exceeding 1,000 W/m². You need to account for dust and sand accumulation affecting surface characteristics, requiring textured finishes that resist particulate embedding while maintaining cleanability. Our technical team would advise addressing thermal shock resistance for installations where irrigation systems create temperature differentials of 60-80°F within seconds, imposing stresses that cause inferior materials to develop surface checking and micro-fractures.

Comparison Criteria for Supplier Selection

When you develop comparison frameworks for evaluating multiple paving stones suppliers Arizona, you need standardized criteria enabling objective assessment across diverse operational models. Your evaluation matrix should weight factors according to project-specific priorities—delivery reliability may dominate for time-sensitive commercial projects, while technical support importance increases for complex installations with challenging site conditions. You’ll find that creating supplier scorecards documenting performance across 10-12 criteria provides clear differentiation that supports defensible selection decisions.

Price comparison requires normalization accounting for included services and delivery terms that vary significantly between suppliers. You should calculate total delivered cost per square foot including freight charges, off-loading requirements, and restocking fees for unused materials. Natural stone dealers Phoenix operations offering free delivery within 50 miles provide value advantages over lower base prices requiring separate freight arrangements. Your cost analysis must incorporate payment terms, as 2% net-30 discounts effectively reduce material costs by amounts that swing competitive positions between suppliers offering similar pricing.

- You need to evaluate material quality consistency across multiple shipments, not just initial samples

- Your assessment should include supplier responsiveness measured through quote turnaround times and inquiry response patterns

- You must consider warehouse locations and their impact on delivery lead times to your typical project sites

- You should verify technical support availability through direct conversations with staff who would support your projects

- Your evaluation must include reference checks with architects and contractors who have completed multiple projects through each supplier

The stone supplier product range breadth affects your ability to consolidate sourcing through single vendors versus managing relationships with multiple specialized suppliers. You gain administrative efficiency when one supplier provides complete material packages, but you risk quality compromises if breadth comes at the expense of category expertise. Your sourcing strategy should balance these competing priorities based on project portfolios—designers working across diverse project types benefit from comprehensive suppliers, while specialists focusing on specific building types may optimize through category-expert relationships.

Emerging Trends and Innovations

You should monitor product innovations emerging from progressive paving stones suppliers Arizona who invest in material technology development and processing enhancements. Recent advances include precision water-jet cutting enabling complex custom patterns, thermal treatment processes reducing surface temperatures by 20-25°F, and penetrating sealers providing stain protection without altering natural appearance. When you specify these innovative products, you deliver performance benefits that conventional materials cannot match, creating competitive advantages for projects where cutting-edge solutions justify premium pricing.

Digital visualization tools offered by forward-thinking premium paving stones Arizona suppliers enable you to evaluate layout options and color combinations before material procurement. These platforms allow uploading site photos and overlaying various material selections with accurate color representation and scale visualization. You can share these renderings with clients for approval processes that reduce revision cycles and change orders resulting from expectation mismatches. The suppliers investing in these technologies demonstrate commitment to customer success extending beyond simple product transactions.

Sustainability innovations continue advancing as natural stone dealers Phoenix operations respond to increased environmental awareness and green building certification requirements. You’ll find suppliers offering carbon-neutral shipping options, recycled packaging materials, and materials from quarries implementing renewable energy systems. When you specify products from these environmentally progressive sources, you support LEED credit achievement while meeting corporate sustainability mandates increasingly common in commercial development projects.

Critical Success Factors

Your long-term success in paving stone specification and procurement depends on cultivating relationships with reliable paving stones suppliers Arizona who function as collaborative partners rather than transactional vendors. The difference between adequate suppliers and exceptional ones becomes evident during challenging situations—material shortages, expedited delivery requirements, field performance issues—when you need creative problem-solving and flexible accommodation rather than rigid policy enforcement. You should invest time developing these strategic relationships with suppliers who demonstrate consistent reliability across multiple projects.

Professional networks provide invaluable intelligence about supplier performance that formal evaluation processes cannot reveal. You gain insights through conversations with peers who share experiences about delivery reliability, technical support quality, and warranty claim handling. When you participate actively in professional associations and industry groups, you access collective knowledge that informs better supplier selection decisions. The stone paving suppliers directory resources available through these networks highlight vendors with proven track records versus newer operations lacking performance histories.

Your specification expertise grows through continuous learning about material science advances, installation technique evolution, and performance documentation from completed projects. You should maintain relationships with multiple suppliers who expose you to different product innovations and regional best practices. When you diversify your supplier network strategically, you gain comparative perspectives that sharpen your technical judgment and enhance your value to clients. For additional implementation guidance, review Customer ratings and reviews of Arizona paving slab suppliers before you finalize your project specifications and supplier commitments. Citadel Stone manufactures precision-drilled paving slabs for anchoring and distributes them across Arizona.