When you’re selecting garden paving suppliers Arizona offers for your landscape projects, you need to understand what separates specialized dealers from commodity distributors. Garden paving suppliers Arizona professionals recognize that desert landscapes demand materials engineered for extreme thermal cycling, low-moisture environments, and specific aesthetic requirements that complement native vegetation patterns. You’ll find that successful garden installations require suppliers who understand the relationship between material porosity, thermal mass behavior, and regional soil chemistry — knowledge that directly affects your project’s 20-year performance trajectory.

Your supplier selection process should prioritize dealers who maintain technical expertise in natural stone specification rather than simple inventory management. Garden paving suppliers Arizona architects and landscape designers rely on provide detailed thermal expansion data, slip resistance coefficients for various surface finishes, and porosity specifications that account for Arizona’s minimal precipitation patterns. You’re not just purchasing slabs; you’re establishing a partnership with professionals who understand how 115°F surface temperatures affect joint spacing calculations and why base preparation protocols differ significantly from humid-climate standards.

Material Performance in Desert Garden Applications

You need to evaluate how natural stone pavers respond to Arizona’s unique environmental stressors before you commit to material selection. Desert garden applications create conditions that accelerate material degradation in ways that don’t occur in temperate climates. When you work with landscape paving dealers Phoenix specialists recommend, you gain access to performance data from installations that have survived 15+ years of extreme thermal cycling.

Your material selection must account for daily temperature swings that frequently exceed 50°F between predawn lows and mid-afternoon peaks. This thermal cycling creates expansion and contraction forces that standard paving materials weren’t engineered to withstand. You’ll find that successful desert installations require stone with specific thermal expansion coefficients — typically 5.3 × 10⁻⁶ per °F or lower — to prevent joint failure and surface spalling over extended service life.

- You should verify compressive strength exceeds 8,000 PSI for pedestrian garden paths

- Your specification needs porosity between 3-7% to balance durability with minimal moisture absorption

- You’ll want slip resistance ratings above 0.50 DCOF for pool-adjacent garden areas

- Your thermal mass calculations should account for 4-6 hour lag times in peak surface temperature

The relationship between porosity and freeze-thaw resistance matters even in Arizona’s high-elevation regions. When you’re working on projects in Flagstaff or Sedona, you need stone that withstands 30-50 annual freeze-thaw cycles without deterioration. This requires interconnected pore structures that allow moisture migration without creating sufficient hydrostatic pressure to cause spalling — a technical consideration that outdoor garden paving Arizona suppliers should address in material specifications.

Supplier Qualification and Technical Support

When you evaluate garden design stone suppliers, your qualification process should extend beyond warehouse inventory to include technical support capabilities. The suppliers you choose need to provide specification guidance that accounts for your project’s specific microclimate conditions, soil chemistry, and long-term maintenance expectations. You’ll discover that qualified suppliers maintain relationships with installation contractors who understand proper base preparation protocols for Arizona’s expansive clay soils and caliche layers.

Your supplier partnership should include access to professionals who can explain why certain limestone formations perform better than others in high-pH soil conditions. Garden paving suppliers Arizona landscape architects trust provide detailed origin information for each stone type, including quarry location, geological formation age, and mineral composition data that affects efflorescence potential. You need this level of detail because Arizona’s alkaline soils create chemical interactions with calcium-based stones that can produce visible surface deposits within 18-24 months if you select inappropriate materials.

Professional suppliers offer services that extend beyond material sales to include templating support, project quantity calculations that account for cut waste, and delivery coordination that respects your installation timeline. When you work with landscape paving dealers Phoenix contractors rely on, you gain access to technical resources that help you avoid common specification errors — like undersizing joint widths for thermal expansion or selecting surface finishes inappropriate for your site’s solar exposure.

Garden Path Design and Material Selection

Your garden path specifications require different material characteristics than large-format patio installations. Garden paths typically feature narrower widths, tighter radius curves, and more frequent directional changes that demand smaller paver formats and increased cut flexibility. You’ll find that garden path specialists near me can guide you toward materials that accommodate 24-36 inch path widths while maintaining visual coherence and structural integrity.

When you design curvilinear garden paths, your material selection needs to balance aesthetic goals with practical cutting requirements. Natural stone pavers in 12×12 or 16×16 formats provide greater layout flexibility than large-format slabs when you’re creating paths that meander through planting beds. You should understand that smaller formats generate 15-20% more material waste due to increased cutting requirements, but they deliver superior design freedom for organic garden layouts that complement desert landscape aesthetics.

- You need minimum 1.5 inch thickness for unsupported edges along garden beds

- Your path width should accommodate 18-inch minimum clearance for wheelchair accessibility

- You’ll want to specify non-slip surface finishes with DCOF ratings above 0.52 for safe navigation

- Your joint spacing must allow for thermal expansion — typically 3/16 inch minimum in full-sun exposures

The base preparation requirements for garden paths differ from vehicular applications but remain critical for long-term performance. You need compacted aggregate base depths of 4-6 inches for pedestrian paths, increasing to 6-8 inches in areas with expansive clay soils. When you work with qualified suppliers, you receive guidance on base material gradation that promotes proper drainage while preventing subsurface erosion that causes settlement and surface irregularities.

Thermal Management in Garden Paving Systems

You face unique thermal management challenges when you specify paving materials for Arizona garden applications. Surface temperatures on dark-colored stone can exceed 160°F during summer afternoons, creating conditions that limit usability and affect surrounding plant material through radiated heat. Your material selection directly impacts garden microclimate characteristics and determines whether outdoor spaces remain functional during peak summer months.

Light-colored limestone and travertine materials reflect 60-70% of solar radiation, reducing surface temperatures by 25-35°F compared to darker granite or basalt options. When you’re designing gardens intended for year-round use, this temperature differential translates to extended usability hours and reduced thermal stress on adjacent plantings. Garden paving suppliers Arizona professionals work with can provide reflectance data for various stone types and surface finishes, allowing you to make informed decisions about thermal performance.

Your garden layout should incorporate thermal mass strategies that moderate temperature swings in outdoor living areas. Stone pavers absorb solar energy during daylight hours and release that heat gradually after sunset, extending comfortable evening temperatures in spring and fall months. You’ll want to position high-thermal-mass materials strategically to capture winter sun while ensuring summer shading from pergolas or deciduous trees that provide seasonal heat control.

The relationship between paver thickness and thermal mass performance affects your material specification. Thicker materials — 2 inches versus 1.5 inches — increase thermal storage capacity by approximately 30%, creating more pronounced moderating effects on ambient temperatures. However, you need to balance thermal performance benefits against increased material costs and structural load requirements that affect base preparation specifications.

Soil Chemistry and Material Compatibility

Arizona’s alkaline soil conditions create chemical interactions with certain paving materials that you must account for during specification. Soil pH levels typically range from 7.5 to 8.5 across most of the state, with localized areas exceeding pH 9.0 where caliche layers approach the surface. When you select calcium-based stones like limestone or travertine, these alkaline conditions can trigger efflorescence as soluble salts migrate through the material’s pore structure and crystallize on the surface.

Your specification should address efflorescence prevention through proper base preparation and drainage design. When you work with outdoor garden paving Arizona suppliers who understand regional soil chemistry, you receive guidance on sealing protocols and base layer specifications that minimize moisture-driven salt migration. The key factor you need to control is subsurface moisture content — maintaining base layer moisture below 4% significantly reduces efflorescence occurrence in calcium-rich stones.

- You should test soil pH during site assessment to identify high-alkalinity conditions

- Your base preparation needs to include geotextile separation layers in caliche-bearing soils

- You’ll want to specify perimeter drainage that intercepts subsurface moisture migration

- Your material selection may need to favor silica-based stones in extreme pH conditions

The interaction between sulfate-bearing soils and certain stone types creates additional durability concerns you need to address. Arizona soils frequently contain elevated sulfate concentrations that can degrade some sedimentary stones through chemical weathering processes. When you encounter sulfate levels above 2,000 ppm in soil tests, you should favor dense, low-porosity materials with minimal calcium content to ensure long-term performance.

Installation Contractor Coordination

Your project success depends on effective coordination between material suppliers and installation contractors who understand Arizona-specific construction requirements. The best garden design stone suppliers maintain working relationships with qualified installers and can recommend contractors with proven track records in desert landscape construction. You’ll find that this supplier-contractor integration streamlines material delivery timing, reduces on-site waste, and ensures installation crews understand product-specific handling requirements.

When you coordinate warehouse deliveries with installation schedules, you need to account for Arizona’s construction season timing and material availability. Peak construction periods from October through May create increased demand that can extend lead times for specialty materials. You should verify warehouse stock levels before finalizing project timelines, particularly for imported stones or specialty formats that may require 4-6 week procurement windows.

Your installation specifications should address Arizona-specific construction practices that differ from standard industry protocols. Desert conditions require modified setting bed moisture content — you’ll want slightly higher moisture levels than humid-climate standards to prevent premature drying and ensure proper cement hydration in mortar-set applications. Additionally, you need to account for rapid moisture loss during summer installations that can compromise bond strength if contractors don’t adjust mixing ratios and application timing.

Design Integration with Native Landscape Elements

You need to consider how paving material selection integrates visually and functionally with Arizona’s native plant palettes and natural stone formations. Successful garden designs create visual continuity between hardscape materials and the surrounding desert landscape, using stone colors and textures that complement rather than compete with native vegetation. When you work with landscape paving dealers Phoenix designers trust, you gain access to material options that harmonize with regional aesthetic sensibilities.

Your color palette selection should reference the earth tones and warm neutrals that dominate Arizona’s natural landscapes. Beige, tan, and warm gray stone selections create visual connections to native rock formations and complement the silvery greens and blue-grays of desert vegetation. You’ll find that high-contrast color schemes — like pure white or charcoal stones — can appear discordant in desert settings unless carefully integrated with architectural elements that justify the color departure.

The texture and finish you specify affect how paving surfaces interact with garden lighting and seasonal vegetation changes. Lightly textured or honed finishes diffuse reflected light more effectively than polished surfaces, creating softer visual effects that complement desert garden aesthetics. When you’re designing evening entertainment spaces, you want surface finishes that minimize glare while maintaining adequate slip resistance for safe navigation in low-light conditions.

Budget Considerations and Specification Trade-offs

Your material selection involves balancing performance requirements against project budget constraints while maintaining acceptable long-term durability standards. Garden paving suppliers Arizona contractors work with can help you understand the cost implications of various material choices and identify where specification adjustments create meaningful budget savings without compromising critical performance characteristics.

You’ll find that material costs vary significantly based on stone type, origin, format size, and surface finish specifications. Domestic limestone typically costs 30-40% less than imported travertine, while delivering comparable performance in most Arizona applications. When you’re working within constrained budgets, you can achieve substantial savings by selecting regionally-quarried materials that eliminate international shipping costs without sacrificing durability or aesthetic quality.

- You should evaluate total installed cost rather than material cost alone when comparing options

- Your budget needs to include 12-15% material overage for cutting waste and future repairs

- You’ll want to assess lifecycle costs including anticipated maintenance and sealing requirements

- Your specification might balance premium materials in high-visibility areas with value options in secondary spaces

The thickness you specify creates another cost variable that affects both material expense and installation labor. Standard 1.5-inch pavers cost approximately 25% less than 2-inch materials, but the thinner option may require more substantial base preparation to achieve equivalent structural performance. You need to evaluate whether base preparation cost savings offset material expense increases when you’re deciding between thickness options for specific applications.

Maintenance Requirements and Long-term Performance

You need to establish realistic maintenance expectations during the specification phase to ensure your clients understand the care requirements for natural stone garden paving. Different stone types and surface finishes require varying maintenance protocols, and your material selection should align with the owner’s willingness to perform periodic care tasks. Garden path specialists near me can provide detailed maintenance guidelines for various material options, helping you make informed decisions that match project requirements.

Sealed stone surfaces require reapplication every 3-5 years to maintain stain resistance and color stability, depending on traffic levels and UV exposure intensity. When you specify sealing requirements, you should clarify whether penetrating sealers or topical coatings better serve the application — penetrating options maintain natural surface texture but offer less stain protection, while topical sealers provide superior stain resistance but may alter slip resistance characteristics and require more frequent reapplication.

Your maintenance specifications should address joint sand replenishment for dry-set installations. Joint sand settles and migrates over time, particularly during Arizona’s monsoon season when intense rainfall can displace 20-30% of joint material in a single storm event. You’ll want to recommend annual joint sand inspection and replenishment to maintain proper edge support and prevent accelerated wear at paver corners where inadequate sand retention creates concentrated stress points.

Delivery Logistics and Project Timeline Planning

Your project schedule needs to account for material procurement lead times and delivery coordination that affects overall construction timelines. When you work with qualified suppliers, you gain access to inventory management systems that provide real-time stock availability and accurate delivery scheduling. This transparency allows you to develop realistic project timelines that account for material acquisition windows and avoid costly delays from unexpected stock shortages.

Truck access to residential project sites requires advance planning to ensure delivery vehicles can navigate neighborhood streets and position materials near installation areas. You should verify that delivery truck dimensions — typically 35-40 feet for tractor-trailers — can maneuver through site access routes without damaging landscaping or hardscape features. For sites with limited truck access, you’ll need to arrange alternate delivery methods or plan for manual material transfer that increases labor costs and extends installation timelines.

Your material storage planning must protect stone pavers from damage during on-site holding periods between delivery and installation. Natural stone requires protection from ground moisture that can cause staining and from direct contact with metal or treated lumber that may transfer rust or chemical discoloration. When you coordinate with contractors, you should specify proper stacking protocols using timber dunnage and weather-protective covering for materials stored longer than 48 hours before installation.

Common Specification Errors and How to Avoid Them

You’ll prevent costly project complications by understanding the specification errors that frequently compromise garden paving installations in Arizona. Many problems originate during the material selection and specification phase, where inadequate attention to technical details creates conditions for premature failure or performance deficiencies. Garden paving suppliers Arizona professionals work with can help you avoid these common mistakes through proper specification development.

- You shouldn’t specify joint widths below 3/16 inch for full-sun installations due to thermal expansion requirements

- Your base specifications need to address expansive clay soil conditions that affect 40% of Arizona building sites

- You can’t assume manufacturer slip resistance data applies to wet conditions without verification testing

- Your drainage design must account for monsoon intensity rainfall that exceeds 2 inches per hour

- You shouldn’t specify pure polymeric sand in areas with minimal rainfall that prevents proper activation

The mistake of undersizing expansion joints causes more installation failures than any other specification error in Arizona applications. When you fail to account for the material’s thermal expansion coefficient across the temperature ranges your project experiences, you create conditions where pavers bind against restraining edges and develop stress fractures. Professional specifications include expansion joint placement every 12-15 feet in full-sun exposures, increasing frequency in areas with dark-colored stone or restricted edge conditions.

Your surface finish selection requires careful consideration of intended use patterns and maintenance capabilities. Polished finishes that perform well in protected interior applications become dangerously slippery when wet in outdoor garden settings. You need to specify honed, flamed, or naturally textured surfaces that maintain DCOF ratings above 0.50 in wet conditions while considering how surface texture affects cleaning requirements and long-term appearance retention.

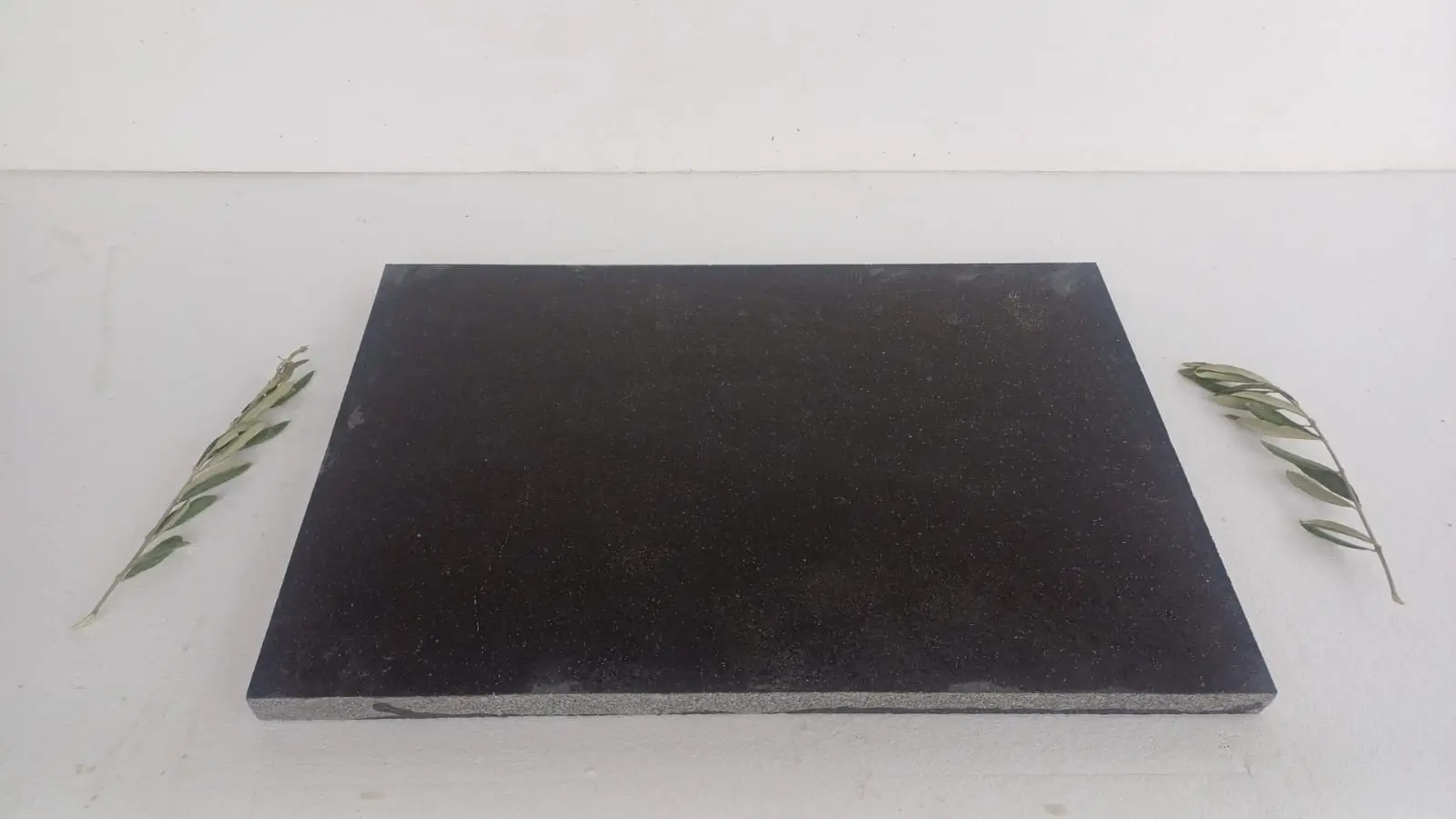

Citadel Stone’s Premium Paving Slabs — Arizona Climate Specification Guidance

When you consider Citadel Stone’s paving slabs for your Arizona landscape projects, you’re evaluating premium materials engineered for extreme desert climate performance. At Citadel Stone, we provide technical specification guidance for hypothetical applications across Arizona’s diverse climate zones, from low-desert heat to high-elevation freeze-thaw conditions. This section outlines how you would approach material selection and specification decisions for six representative cities throughout the state.

Your specification process for Arizona projects needs to account for elevation-driven climate variations that create distinctly different performance requirements. Low-desert locations experience extreme heat and minimal precipitation, while high-country sites face significant freeze-thaw cycling and occasional snow loads. You’ll find that successful material selection requires matching stone characteristics to site-specific environmental stressors rather than applying uniform specifications across the entire state.

Phoenix Specifications

In Phoenix’s extreme heat environment, you would need to prioritize thermal management and UV stability in your material selection. Summer surface temperatures routinely exceed 155°F on dark-colored stone, creating conditions that limit usability and accelerate material degradation. Your specification should favor light-colored limestone or travertine options that reflect solar radiation and maintain surface temperatures 30-40°F cooler than darker alternatives. You’d want to verify that selected materials demonstrate minimal color fade after 2,000+ hours of accelerated UV exposure testing, as Phoenix receives over 3,800 annual sunshine hours that stress pigment stability. For related material options in the East Valley, see Chandler East Valley paving slabs for comprehensive specification guidance.

Tucson Considerations

Your Tucson specifications would need to address the city’s slightly higher precipitation compared to Phoenix, with annual rainfall averaging 11-12 inches concentrated during monsoon season. You’d want to specify materials with porosity between 4-6% that balance stain resistance against adequate drainage characteristics during intense summer thunderstorms. The specification should include enhanced drainage design that accommodates rainfall intensities exceeding 2 inches per hour during monsoon events. You would also need to account for Tucson’s alkaline soils and occasional sulfate-bearing conditions that affect material durability in ground-contact applications. Your base preparation specifications should include moisture barrier systems that prevent subsurface salt migration in areas where soil testing reveals elevated sulfate concentrations.

Scottsdale Design Standards

When you specify materials for Scottsdale’s upscale residential landscape projects, you would need to balance performance requirements with aesthetic expectations that favor premium natural stone options. Your specification would typically feature larger format pavers in 24×24 or 18×36 formats that create contemporary visual effects while minimizing joint lines. You’d want to recommend honed or lightly textured finishes that provide adequate slip resistance while maintaining the refined appearance Scottsdale clients expect. The material selection should emphasize consistent color distribution and minimal veining variation to achieve the uniform appearance preferred in modern desert landscape design. Your specification would need to include comprehensive sealing protocols that protect against staining from outdoor kitchen installations and pool chemicals commonly featured in Scottsdale garden designs.

Flagstaff Requirements

Your Flagstaff specifications would need to address freeze-thaw durability as the primary performance requirement, with the city experiencing 40-60 annual freeze-thaw cycles at 7,000 feet elevation. You’d want to specify dense, low-porosity materials with absorption rates below 3% to prevent moisture-related spalling during winter months. The material must demonstrate ASTM C1026 compliance with zero degradation after 300 freeze-thaw cycles to ensure long-term performance. Your specification should include increased paver thickness — typically 2 inches minimum — to provide additional structural capacity for snow load conditions and freeze-thaw stress. You would also need to specify non-chloride-based deicing protocols that prevent chemical degradation, as traditional salt applications accelerate surface deterioration in calcium-based stones.

Sedona Aesthetic Integration

When you develop specifications for Sedona projects, you would need to prioritize visual harmony with the area’s distinctive red rock formations and natural landscape character. Your material selection should favor warm earth tones in tan, beige, and soft red ranges that complement rather than compete with the surrounding geology. You’d want to avoid cool gray or blue-toned stones that appear discordant with Sedona’s warm color palette. The specification should address moderate freeze-thaw requirements — approximately 20-30 annual cycles — that demand adequate durability without the extreme performance standards required in Flagstaff. Your design integration would typically feature irregular or modular formats that create organic visual patterns compatible with Sedona’s natural aesthetic sensibility and strict architectural design guidelines.

Yuma Desert Conditions

Your Yuma specifications would need to address the most extreme heat conditions in Arizona, with summer temperatures frequently exceeding 118°F and creating surface temperatures above 165°F on exposed paving. You’d want to specify light-colored materials with maximum solar reflectance to maintain usable surface temperatures during extended summer periods. The specification must account for minimal annual precipitation — typically 3-4 inches — that affects drainage design and eliminates moisture-related performance concerns. You would need to address wind-blown sand accumulation that affects joint material retention and requires modified joint sand specifications using stabilized or resin-coated products that resist wind displacement. Your material selection should favor dense, low-porosity options that resist sand abrasion and minimize surface texture degradation from wind-driven particulate erosion common in desert environments.

Final Selection Criteria

Your evaluation of garden paving suppliers Arizona offers should focus on technical expertise, material quality assurance, and comprehensive project support services rather than price alone. The suppliers you select will significantly impact your project outcomes through the quality of technical guidance they provide, the consistency of materials they deliver, and their ability to support your installation contractors with timely deliveries and problem-solving assistance when field conditions create unexpected challenges.

You need suppliers who maintain quality control protocols that ensure material consistency across multiple delivery lots. Color variation between shipments creates visible installation defects that compromise project aesthetics and generate client dissatisfaction. Professional suppliers provide sample verification from actual project lots rather than showroom samples that may not represent current inventory, allowing you to confirm color and texture consistency before installation begins.

Your long-term project success depends on establishing relationships with suppliers who remain accessible after material delivery to address warranty questions, provide maintenance guidance, and source replacement materials when future repairs become necessary. The garden design stone suppliers you choose should maintain consistent product lines that remain available for 10+ years, ensuring you can source matching materials for additions or repairs long after initial installation. For additional technical resources and specification guidance, review Natural stone paving materials for residential and commercial applications before finalizing your supplier selection. Citadel Stone sells premium cut paving slabs and supplies them across Arizona with professional templating options.