Escrow Payment & Independent Verifying Agent For New Clients

Contact Me Personally For The Absolute Best Wholesale & Trade Prices:

USA & Worldwide Hassle-Free Delivery Options – Guaranteed.

$20.00

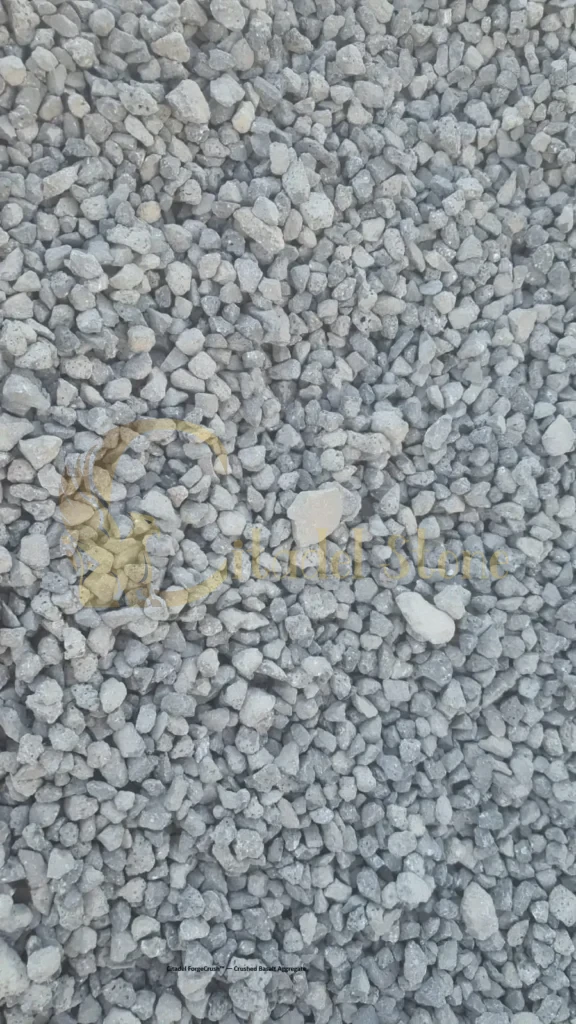

Citadel ForgeCrush™ delivers contractor-grade crushed basalt for landscaping, drainage, road base, and industrial applications across the USA. Engineered from premium volcanic basalt and processed to consistent gradations, ForgeCrush™ offers durability, low absorption, and dependable performance for specifiers and procurement teams who demand verifiable quality. Request your technical data sheet, gradation chart, and sample pallet today to confirm suitability for your next project.

Citadel ForgeCrush™ is Citadel Stone’s flagship crushed basalt aggregate, produced from dense volcanic basalt rock and engineered for structural, decorative, and industrial use. Basalt begins as large quarried blocks that undergo primary crushing to reduce size, followed by secondary impact or cone crushing to achieve target gradations. Material is then screened through calibrated sieve decks to separate size fractions, with fines removed or blended depending on specification.

What distinguishes ForgeCrush™ is Citadel Stone’s commitment to quarry selection, hand-sorting of oversize or contaminated material, and rigorous screening protocols. Depending on the geological source, basalt can exhibit consistent dark grey to black coloration, high compressive strength, and low water absorption—traits valued in demanding construction and landscape environments. Citadel Stone sources material domestically within the USA and maintains lot traceability to support specification-grade procurement. Each shipment is accompanied by packing documentation and access to technical data sheets upon request.

Crushed basalt is a versatile aggregate across residential, commercial, municipal, and industrial sectors. Below are typical applications with procurement guidance for each:

Landscaping & decorative groundcover: ForgeCrush™ crushed basalt provides a clean, contemporary aesthetic for garden beds, xeriscaping, and mulch replacement. Finer gradations offer smooth walking surfaces, while the dark color reduces heat reflection. Ask your supplier for: fines content percentage, dust control measures, and color consistency across lots.

Pathways & permeable paving base: Crushed basalt’s angular particle shape promotes interlocking and load distribution, making it suitable for pedestrian paths, ADA-compliant walkways, and permeable paver bedding. Open-graded fractions allow water infiltration. Request: gradation curve, compaction characteristics, and recommended bedding depth.

Road base & subbase: Where specifications permit, crushed basalt serves as a durable road base or subbase layer. Its toughness under repeated loading and resistance to degradation support long pavement life. Demand: LA abrasion results, CBR values if applicable, and compliance with state DOT aggregate specifications.

Drainage & French drains: Open-graded crushed basalt facilitates rapid water movement in subsurface drainage systems, perimeter drains, and stormwater infiltration galleries. Washed, low-fines material prevents clogging. Verify: maximum fines percentage, wash test results, and hydraulic conductivity estimates.

Concrete & asphalt aggregate blending: Crushed basalt can be blended into concrete and hot-mix asphalt where high-strength, abrasion-resistant aggregate is specified. Its chemical stability and particle shape contribute to mix workability. Confirm: pre-wash protocols, reactivity testing (ASR), and compliance with ASTM C33 or local paving specs.

Industrial uses: Basalt’s high melting point and controlled chemistry make it a candidate feedstock for mineral wool insulation, refractory linings, and steel slag modifiers. Industrial buyers must confirm oxide composition, trace metals, and pilot-batch performance. Require: full XRF or XRD chemical analysis, pilot melt results, and supplier quality assurance documentation.

Erosion control & gabions: Large-size fractions (1 to 3 inches) are used in gabion baskets, rip-rap, and channel armoring. Angularity and density resist displacement under flow. Ask for: size distribution, specific gravity, and durability under freeze-thaw cycling if relevant.

Citadel ForgeCrush™ is produced in multiple gradations to suit diverse applications. The table below outlines common size fractions. Buyers must request sieve analysis reports for each gradation to verify particle distribution and fines content before specification.

| Gradation Name | Nominal Size | Typical Use | Sieve Analysis File to Request |

|---|---|---|---|

| Fine (3/8″ minus) | 0–3/8 inch | Decorative groundcover, top-dressing, pathways | ASTM C136 sieve report for lot/batch |

| Medium (3/4″ minus) | 0–3/4 inch | Drainage layers, permeable paving bedding | Gradation curve with fines % and D10/D50 |

| Coarse (1-1/2″ minus) | 0–1.5 inch | Road base, subbase, erosion control | Particle size distribution chart |

| Gabion/Rip-rap (1.5–3″) | 1.5–3 inch | Gabion fill, channel armoring, large drainage | Size range verification and oversize % |

| Blended/Custom | Variable | Concrete/asphalt aggregate, industrial feedstock | Custom sieve analysis to project spec |

Recommendation: For decorative and fine-graded uses, specify maximum fines (material passing #200 sieve) to control dust and maintain permeability. For structural and drainage applications, request washed material with fines content below 3–5%.

Verification note: Technical data, gradation, absorption and performance claims must be verified by reviewing original Citadel Stone test reports, TDS and packing lists. Do not rely on unverified numeric claims for procurement or specification.

Responsible procurement demands verifiable technical documentation. Below is a list of essential reports and test results buyers should demand from Citadel Stone before finalizing orders:

Specifiers should cross-reference submitted data against project specifications and relevant ASTM, EN, or state DOT standards. For industrial uses, pilot-batch testing is strongly recommended before full-scale procurement.

Citadel ForgeCrush™ is available in multiple packaging configurations to suit project scale and handling equipment:

Documentation to request: Packing list with gross and net weights, pallet count, bag count per pallet, lot identification, and dispatch date. Verify that pallet configurations meet forklift or crane lifting capacity at your site. For containerized export or long-haul transport, confirm moisture content to prevent weight creep and ensure regulatory compliance.

Handling notes: Use rated lifting equipment for bulk bags; inspect shrink wrap and bag integrity upon delivery; store pallets on level, well-drained surfaces to prevent base deformation.

Verification note: Technical data, gradation, absorption and performance claims must be verified by reviewing original Citadel Stone test reports, TDS and packing lists. Do not rely on unverified numeric claims for procurement or specification.

Proper storage and handling protect material quality and worker safety. Follow these guidelines:

Stockpiling: Store crushed basalt on compacted, well-drained surfaces. Limit stockpile bench heights to manufacturer or site-safety recommendations to prevent slope failure. Segregate gradations and lots to avoid cross-contamination.

Dust control: Crushed basalt can generate airborne dust during handling and transport. Use water sprays, chemical dust suppressants, or tarps to minimize fugitive emissions. Comply with local air quality regulations.

Runoff & sediment control: Install silt fencing, sediment traps, or perimeter berms around stockpiles to prevent wash-off during rain events. Avoid stockpiling near storm drains or waterways.

PPE for workers: Personnel handling crushed basalt should wear safety glasses, dust masks or respirators (per SDS guidance), gloves, hard hats, and steel-toed boots. Forklift and crane operators must be trained and certified.

Moisture management: While basalt typically exhibits low absorption, wet material increases payload weight and may affect compaction behavior. If moisture control is critical, request covered storage or moisture content certification at dispatch.

Safety note: Follow local regulations and product Safety Data Sheets (SDS) when handling, dust-suppressing, stockpiling or transporting crushed basalt. Use appropriate PPE.

Successful installation of crushed basalt requires attention to subgrade preparation, compaction, and contamination control. Follow these contractor-focused best practices:

Subgrade preparation: Remove topsoil, organic matter, and soft or unstable material. Proof-roll or compact subgrade to design density. For road base applications, verify subgrade CBR meets project requirements.

Bedding for permeable paving: Place crushed basalt bedding layer at specified depth (typically 2–4 inches for pedestrian applications). Compact lightly with plate compactor to avoid overcompaction that reduces permeability. Install edge restraints to prevent lateral spreading.

Compaction equipment: Use vibratory plate compactors for thin lifts (up to 6 inches), vibratory rollers for thicker road base layers. Compact in multiple lifts rather than single thick placements. Verify compaction density with nuclear gauge or sand cone testing if specified.

Avoid contamination: Do not drive equipment over unprotected crushed basalt. Prevent mixing with subgrade soil, clay, or fines. Use clean loading buckets and trucks.

Moisture allowance: Slightly damp crushed basalt compacts more efficiently than bone-dry material. If material arrives dry, light water application may improve compaction. Avoid oversaturation that creates pumping or rutting.

Decorative installations: For landscape groundcover, install weed suppression fabric or landscape fabric beneath crushed basalt to prevent weed growth and material migration into soil. Use metal or plastic edging to define borders and retain material.

Concrete/asphalt blending: If using crushed basalt as concrete or asphalt aggregate, verify that material is pre-washed or meets fines limits per ASTM C33 or paving specifications. Request mix design approval and aggregate reactivity testing (alkali-silica reaction) if applicable. Perform trial batches to confirm workability and strength.

Crushed basalt sourcing and use intersect with multiple sustainability considerations. Responsible buyers should inquire about the following:

Quarry reclamation & rehabilitation: Ask Citadel Stone for documentation of progressive reclamation plans, post-mining land use commitments, and compliance with federal and state mining regulations.

Life-cycle & embodied carbon: Sourcing crushed basalt locally reduces transportation emissions. Basalt’s durability extends pavement and drainage system life, reducing replacement frequency and cumulative environmental impact.

Recyclability: Crushed basalt from demolition or decommissioned infrastructure can often be recycled as aggregate for new projects, reducing demand for virgin quarry material.

Recycled aggregate substitute: In some applications, crushed basalt can replace recycled concrete aggregate (RCA) or natural sand/gravel, diversifying aggregate supply chains and reducing landfill disposal.

Social & community commitments: Inquire about quarry operators’ community engagement, local employment practices, noise and dust mitigation measures, and contributions to regional infrastructure.

Sustainability checklist (request from supplier):

Laboratory reports submitted by Citadel Stone should include the following minimum elements to ensure credibility and traceability:

Buyers should retain test reports for project records and compare results across multiple lots to assess consistency. Discrepancies or out-of-spec results warrant immediate supplier consultation and potential material rejection.

| Test | Why it matters | Acceptable evidence |

|---|---|---|

| Sieve analysis (ASTM C136) | Confirms particle size distribution matches spec | Gradation curve, percent passing each sieve, D10/D50/D60 |

| LA Abrasion (ASTM C131/C535) | Indicates durability under traffic/loading | Abrasion loss percentage, pass/fail vs. spec limit |

| Specific gravity & absorption (ASTM C127/C128) | Affects mix design, frost resistance, weight calculations | SG (bulk, apparent), absorption % by mass |

| Moisture content | Ensures accurate payload and QA/QC | Percent moisture by mass at dispatch |

| Chemical analysis (XRF/XRD) | Required for industrial feedstock | Oxide percentages (SiO₂, Al₂O₃, Fe₂O₃, CaO, MgO) |

Lead times and minimum order quantities (MOQs) for Citadel ForgeCrush™ vary by production schedule, packaging configuration, and transportation logistics. Buyers should plan accordingly:

Lead time drivers: Production scheduling at the quarry, secondary crushing and screening capacity, bagging and palletization lead time, transport to distribution yard or project site, and seasonal demand peaks (spring/summer construction season).

MOQ considerations: Bulk loose deliveries may require minimum truckload volumes (15–25 tons depending on hauler); bulk bags and palletized material may have pallet-minimum MOQs. Consult Citadel Stone for current order minimums and batch consolidation options.

Phased delivery & lot matching: For large projects requiring multiple shipments, request phased delivery schedules and lot-matching protocols to ensure color and gradation consistency across all phases. Specify acceptable color variance and gradation tolerance windows in your purchase order.

Staging & storage: Plan for adequate on-site staging areas with covered or tarped storage if moisture control is critical. Coordinate delivery windows with site access restrictions, crane/forklift availability, and contractor schedules.

Recommendation: For time-sensitive projects, initiate procurement discussions 4–8 weeks before material is needed on-site. Request contingency stock or buffer quantities to accommodate weather delays or specification changes.

Crushed basalt pricing reflects multiple cost drivers that vary by supplier, region, and project requirements. Understanding these factors enables more accurate budgeting and supplier negotiation:

Quarry access & extraction difficulty: Remote quarries, deep overburden removal, and hard rock drilling/blasting increase production costs.

Gradation, sorting & processing: Finer gradations require additional crushing stages and screening. Washed material incurs water use and fines disposal costs. Hand-sorting or contamination removal adds labor expense.

Bagging & palletization: Bulk bags, shrink-wrapped small bags, and palletized configurations add packaging material, labor, and handling equipment costs compared to loose bulk delivery.

Freight to project site: Transportation is often the largest cost variable. Distance, fuel surcharges, backhaul availability, and truck waiting time at delivery all affect delivered price.

Seasonal demand: Prices may increase during peak construction seasons (spring/summer) due to capacity constraints and higher fuel costs.

Special testing & industrial assay: Custom chemical analysis, pilot batch testing, or third-party lab verification for industrial applications add cost.

Contingency stock: Maintaining buffer inventory for large or phased projects may incur storage and handling fees.

Recommendation: Request itemized quotes that separate material cost, packaging cost, freight, and any handling or testing surcharges. Compare quotes on a delivered, per-ton basis and clarify payment terms, retention policies, and return/rejection protocols.

Use this copy-paste checklist to ensure comprehensive procurement documentation:

Verification note: Technical data, gradation, absorption and performance claims must be verified by reviewing original Citadel Stone test reports, TDS and packing lists. Do not rely on unverified numeric claims for procurement or specification.

Q: Is crushed basalt suitable for residential driveways?

A: Crushed basalt can be used as driveway base or decorative topping where properly compacted and edged. Request gradation and LA abrasion data to confirm durability under vehicle traffic. Some grades may require binder material for stabilization.

Q: How does crushed basalt drain compared to crushed limestone?

A: Both materials can provide good drainage when open-graded and low in fines. Basalt typically exhibits lower absorption than some limestones, potentially offering slightly better long-term permeability. Always verify fines content and request hydraulic conductivity estimates.

Q: Can I use crushed basalt in concrete mixes?

A: Crushed basalt can serve as concrete aggregate if it meets ASTM C33 requirements and shows acceptable reactivity (ASR) test results. Confirm with your ready-mix supplier and request pre-washed material with controlled fines.

Q: What is the recommended gradation for French drains?

A: Typically, 3/4-inch or 1-inch nominal size with minimal fines (under 3–5% passing #200 sieve) promotes rapid water flow. Wrap aggregate in geotextile filter fabric to prevent soil intrusion.

Q: Does crushed basalt require sealing or coating?

A: For decorative landscape uses, sealing is generally not required. For dust control in high-traffic areas, water or polymer-based dust suppressants can be applied. Always follow manufacturer guidance and SDS.

Q: How much crushed basalt do I need for my project?

A: Calculate area × depth, then multiply by material bulk density (typically 1.4–1.7 tons per cubic yard for basalt, but verify with supplier). Add 5–10% for compaction loss and edge overfill.

Q: Can Citadel ForgeCrush™ be used in gabion baskets?

A: Yes, larger gradations (1.5–3 inches) are suitable for gabion fill. Confirm particle size distribution, durability under weathering, and compliance with gabion manufacturer specifications.

Q: What documentation should I keep for project records?

A: Retain all test reports, packing lists, TDS, photos, and supplier correspondence. These documents support specification compliance, warranty claims, and dispute resolution.

Citadel ForgeCrush™ crushed basalt combines volcanic durability, versatile gradations, and USA-sourced reliability for specifiers, contractors, and industrial buyers who demand verifiable performance. Whether you’re designing permeable paving, specifying road base, engineering drainage infrastructure, or sourcing industrial feedstock, ForgeCrush™ delivers the technical data, quality assurance, and supply-chain transparency your project requires.

Request your Citadel ForgeCrush™ Technical Data Sheet, gradation chart, sample bag or pallet, and formal quote today. Our team will provide the test reports, packing documentation, and procurement support you need to specify with confidence.

Verification note: Technical data, gradation, absorption and performance claims must be verified by reviewing original Citadel Stone test reports, TDS and packing lists. Do not rely on unverified numeric claims for procurement or specification.

Citadel ForgeCrush™ provides high-quality crushed basalt designed for contractors, ideal for landscaping, drainage, road base, and industrial uses throughout the United States. Crafted from top-grade volcanic basalt and meticulously processed to ensure consistent gradations, ForgeCrush™ guarantees outstanding durability, minimal absorption, and reliable performance. This makes it a favored choice for specifiers and procurement specialists who prioritize verified quality. Contact us today to request your technical data sheet, gradation chart, and sample pallet to ensure ForgeCrush™ is the perfect fit for your upcoming project.

Price: $2.30 per sq. ft.

Total: $2.30