Quick Verdict — Repair, Patch or Replace? (short executive answer)

Replace if: Widespread delamination (more than 20% of surface area), substrate failure (cracked concrete or compromised waterproofing), systematic installation defects (no expansion joints, improper slope), or deck is 15+ years old with recurring problems. Full replacement costs $18–$35/sq ft installed but delivers 25–40 year lifespan with proper materials and installation.

Repair if: Isolated failures (under 10% surface area), substrate is sound, original installation quality was good, and cosmetic issues only (surface spalling, grout loss, minor staining). Repairs cost $8–$18/sq ft for affected areas but expect 5–10 year remaining life maximum.

Immediate safety steps: Mark or barricade loose tiles creating trip hazards. Check pool coping for stability—failed coping presents drowning risk if someone grabs unstable edge. Schedule professional inspection within 2–4 weeks if safety concerns exist.

Why Travertine Fails in Phoenix — Common Failure Modes

Thermal cycling and UV degradation: Phoenix experiences 50–70°F daily temperature swings during summer (115°F afternoon to 85°F dawn). Travertine expands and contracts at different rates than concrete substrate and thinset adhesive, creating shear stresses. Over 10–15 years and thousands of cycles, bond lines fatigue and fail. UV radiation degrades sealers and weakens surface structure, accelerating moisture penetration.

Poor original installation: The majority of travertine failures trace to installation defects—inadequate thinset coverage (less than 95% bonding), wrong adhesive type for Arizona heat (non-modified thinset fails rapidly), missing expansion joints (rigid installations crack), improper substrate preparation (contaminated or insufficiently cured concrete), and inadequate slope for drainage (standing water accelerates deterioration).

Pool chemical attack: Chlorine, acid wash chemicals, and salt (in saltwater pools) chemically attack calcium carbonate in travertine and grout. Acid washing to remove algae etches stone surfaces and dissolves grout, creating pathways for water ingress. Splash zones show accelerated degradation—tiles nearest pool edges fail first.

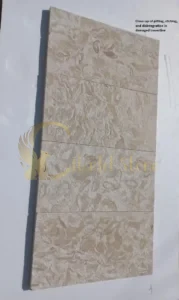

Efflorescence and moisture wicking: Arizona’s hard water and alkaline soils deposit white mineral salts (calcium carbonate, calcium sulfate) on travertine surfaces and within pores. Moisture wicking through porous travertine carries dissolved salts that crystallize at the surface, creating unsightly white deposits and, in severe cases, spalling (surface layer popping off due to subsurface salt crystal pressure).

Substrate movement and settling: Phoenix’s expansive clay soils swell when wet and shrink when dry, causing pool deck substrate movement. Improperly compacted fill around pools settles over 5–10 years, cracking rigid travertine installations. This is particularly common in developments where pool contractors rushed backfill compaction.

Freeze-thaw (high elevation only): In Flagstaff and high-country Arizona (above 5,000 feet), moisture trapped in porous travertine freezes, expands, and causes spalling. Phoenix proper doesn’t experience freeze-thaw, but moisture-related deterioration mimics similar damage patterns.

Delamination from thinset failure: Heat-cycled, moisture-exposed thinset loses adhesive properties. Tiles separate from substrate while remaining visibly intact—creating hollow sounds when tapped and flex underfoot. Eventually, entire sections release, creating serious trip hazards.

Diagnosing Your Deck — What to Inspect (subpoints: grout, bonding, efflorescence, spalling)

Visual surface inspection: Look for cracked tiles (spider-web patterns or clean breaks), missing or crumbling grout, white efflorescence deposits, surface pitting or spalling (flaking), uneven tiles (some raised relative to neighbors), staining patterns indicating water infiltration, and algae or mold growth in joints.

Tap test for delamination: Using a rubber mallet or knuckles, tap tiles systematically across the deck. Solidly bonded tiles produce a dull, solid sound. Delaminated tiles ring hollow—indicating air space beneath. Mark hollow-sounding areas with chalk to map extent of failure. If more than 20% of deck sounds hollow, replacement likely necessary.

Grout and joint condition: Inspect all grout lines for erosion, cracking, or complete loss. Check expansion joints (if present) for sealant condition. Missing grout allows water to reach substrate and thinset, accelerating failure. Cracked grout signals substrate movement.

Efflorescence severity: Light surface efflorescence (white powder easily brushed off) indicates minor moisture issues. Heavy efflorescence with crystalline buildup or surface popping suggests severe subsurface moisture problems requiring substrate investigation.

Coping stability: Pool coping (edge tiles) must be completely stable—any movement indicates urgent safety hazard. Test by attempting to shift coping stones manually. Failed coping presents drowning risk and should be addressed immediately.

Edge and perimeter failures: Deck edges typically fail first due to greater exposure and vulnerability. Check perimeter tiles for looseness, rotation, or complete separation. Edge failures often indicate waterproofing issues.

Slope and drainage verification: Use a 4-foot level to check deck slope—should be minimum 1% (⅛ inch per foot) away from pool and structures. Standing water areas accelerate failure and indicate drainage problems requiring correction during replacement.

Professional assessment tools: Licensed contractors use moisture meters to detect subsurface water, pull tests (mechanically removing sample tiles to measure bond strength), and thermal imaging to identify delaminated zones. Request professional inspection if DIY assessment shows extensive issues or safety concerns.

Repair vs Replace — Cost, Lifespan & Performance Comparison

When spot repair works:

- Isolated failures under 10% total surface area

- Substrate (concrete below) is sound and properly sloped

- Original installation quality was good (proper thinset, expansion joints)

- Access to matching replacement tiles from original lot

- Budget constraints prevent full replacement

- Deck is less than 10 years old

Repair limitations: Patched areas rarely match perfectly (color, texture, wear patterns). Repairs address symptoms, not underlying causes—expect recurring problems within 5–10 years. New thinset bonds to old substrate less effectively than original installation. Moisture trapped in substrate continues damaging adjacent areas.

When full replacement mandatory:

- Hollow sounds across more than 20% of deck area

- Substrate cracked, settled, or improperly sloped

- Systematic installation defects (no expansion joints, wrong adhesive throughout)

- Coping failed or unstable (safety critical)

- Deck age 15+ years with history of recurring repairs

- Desire to upgrade to superior materials preventing future problems

Replacement advantages: Opportunity to correct substrate issues, install proper waterproofing and drainage, specify superior materials (dense basalt, low-absorption travertine, porcelain), incorporate modern details (linear drains, LED lighting), and gain 25–40 year lifespan with warranty. One-time disruption versus repeated repair cycles.

Economic comparison (Phoenix market):

- Spot repair: $8–$18/sq ft for affected areas; 5–10 year remaining life; recurring maintenance

- Full replacement (travertine): $18–$28/sq ft; 20–30 year life if properly installed

- Full replacement (basalt/porcelain): $22–$35/sq ft; 30–40+ year life, lower maintenance

Decision matrix: If repair costs exceed 40% of full replacement cost, or deck will require additional repairs within 5 years, replacement delivers better value. Factor in safety concerns, resale impact, and lifestyle disruption from repeated repairs.

Best Replacement Stones for Phoenix Pool Decks

Dense Basalt & Volcanic Pavers — durability & considerations

Why superior for Phoenix: Basalt’s density (2.9–3.1 g/cm³) and low porosity (<0.5% absorption) create exceptional resistance to Phoenix’s thermal cycling, pool chemicals, and moisture. Mohs 5–6 hardness resists abrasion and impact. Virtually no efflorescence due to minimal water absorption. Expected lifespan 40–60 years in pool applications—often outlasts the pool itself.

Recommended finishes: Flamed or thermal finish provides slip resistance (DCOF ≥0.60) for wet areas while showcasing basalt’s fine-grained texture. Honed basalt works for contemporary designs and maintains safety ratings.

Pros: Longest lifespan available, minimal maintenance (no sealing required), superior chemical resistance, excellent structural strength for coping and heavily loaded areas, modern aesthetic.

Cons: Dark colors (charcoal, black) absorb heat—surface temps 25–40°F above ambient in direct sun (uncomfortable barefoot unless using narrow accent bands or shaded areas). Higher material cost ($14–$24/sq ft). Heavier weight requires robust substrate support.

Phoenix application: Ideal for pool coping and accent bands (6–12 inches wide) framing lighter primary surfaces. Scottsdale luxury pools increasingly use basalt coping with cream travertine or porcelain field pavers—dark frame, cool walking surface combination.

Jointing and coping: Use polymeric sand joints (⅜” width) or epoxy grout in wet zones. Basalt coping should overhang pool edge 1–1½ inches with drip edge detail. Minimum 1¼” thickness for coping, 1½” for decking.

View our Travertine replacement options including basalt and volcanic stone.

White Limestone & Low-Absorption Travertine Alternatives — cool, durable finishes

Why superior for Phoenix: Dense limestone (2.5–2.7 g/cm³, <1% absorption) and premium filled travertine (1–2% absorption) offer classic pool deck aesthetics with significantly better performance than standard travertine. Light colors (white, cream, beige) reflect 50–70% of solar radiation, staying 15–25°F cooler than dark materials—critical for barefoot comfort.

Recommended finishes: Honed or thermal (lightly flamed) for pool decks—smooth enough for comfort, textured enough for slip resistance. Tumbled finish acceptable for rustic applications but requires more frequent cleaning.

Pros: Comfortable surface temperatures year-round, proven Arizona performance when properly installed, moderate cost ($12–$18/sq ft material), broad aesthetic appeal, accepts protective sealers well.

Cons: Requires resealing every 2–3 years, moderate chemical resistance (better than standard travertine, inferior to basalt), still vulnerable to improper installation, shows staining from pool chemicals if not sealed properly.

Phoenix application: Excellent choice for entire deck when budget doesn’t permit basalt, or for primary field pavers with basalt accent borders. Popular in Mesa and Phoenix family pools where cost-performance balance matters.

Jointing and coping: Use ⅜”–½” joints with polymeric sand rated for pool applications. Seal within 2 weeks of installation with breathable, UV-stable penetrating sealer. Limestone coping performs well with proper sealing and drip edges.

Porcelain & Engineered Cool-Surface Pavers — low-maintenance option

Why superior for Phoenix: Engineered porcelain offers near-zero porosity (no sealing ever required), consistent performance lot-to-lot, superior abrasion resistance (PEI 4–5 rating), and excellent UV stability—colors don’t fade over decades. Some manufacturers offer “cool-surface” formulations engineered to minimize heat absorption.

Recommended finishes: Textured or stone-look matte finishes provide slip resistance while maintaining easy cleaning. Avoid smooth glossy porcelain for pool decks—too slippery when wet.

Pros: Lowest maintenance (no sealing, minimal staining), superior chemical resistance to pool treatments, consistent color and texture between orders, excellent for properties where maintenance avoidance is priority (rental properties, vacation homes).

Cons: Higher material cost ($12–$18/sq ft), lacks natural variation some prefer, extremely hard surface feels less organic underfoot than natural stone, requires specialized cutting tools, limited repairability (cracked units must be fully replaced).

Phoenix application: Increasingly popular for complete deck replacement where homeowners prioritize low maintenance. Excellent for Scottsdale luxury pools where consistent appearance matters. Commercial and HOA pools benefit from documented performance and minimal upkeep requirements.

Jointing and coping: Porcelain’s precise dimensions allow tighter joints (¼”–⅜”) with fine polymeric sand or epoxy grout. Some systems use clip spacers for perfect joint consistency. Porcelain coping requires appropriate thinset rated for non-porous materials.

Dense Sandstone & Shellstone — textured choices & maintenance tradeoffs

Why better than standard travertine (but not perfect): Dense, silica-rich sandstone (2.5–2.7 g/cm³) with absorption under 3% offers better performance than soft porous varieties. Shellstone (fossiliferous limestone) in light tones provides natural slip resistance and moderate durability.

Recommended finishes: Natural cleft only for sandstone (sawn finishes unstable). Shellstone works in honed or lightly brushed finishes.

Pros: Natural slip resistance from texture, warm desert tones complement Arizona landscapes, moderate cost ($10–$16/sq ft material), comfortable barefoot temperatures.

Cons: Still porous (3–7% absorption typical)—requires frequent sealing, moderate chemical resistance, variable quality between quarry lots, textured surfaces trap organic debris requiring more frequent cleaning, 20–30 year lifespan maximum.

Phoenix application: Acceptable for budget-conscious replacements where aesthetic priorities texture and natural character over maximum longevity. Works better in low-chemical-exposure areas (spas, adjacent patios) than primary pool splash zones.

Jointing and coping: Requires ½” joints minimum with polymeric sand. Seal aggressively (initial seal plus annual resealing) to maintain performance. Not recommended for coping—use basalt or dense limestone instead.

Installation & Detailing Best Practices to Prevent Future Failure (bedding, drainage, coping)

Substrate preparation: Concrete substrate must be fully cured (28+ days), structurally sound, and properly sloped (minimum 2% away from pool, 1% minimum overall). Repair cracks, divots, and spalls before installing pavers. Shot-blast or acid-etch to create mechanical bond surface. Install waterproof membrane where substrate moisture risk exists.

Thinset selection: Use modified thinset rated for Phoenix heat (140°F+ substrate temperatures) and exterior wet applications. Products specifically formulated for “large format” or “heavy tile” provide better bond. Follow manufacturer mix ratios exactly—too wet causes shrinkage and bond failure.

Thinset coverage: Achieve minimum 95% coverage using appropriate trowel size (½” × ½” notched for most pool pavers). Back-butter large format pavers. Press firmly and check periodically by pulling sample pavers during installation—thinset should cover entire back surface.

Expansion joints: Install expansion joints every 12–16 feet in both directions, at all perimeter transitions (pool coping to deck, deck to house/hardscape), and where deck changes plane. Use compressible backer rod and polyurethane or silicone sealant rated for pool chemicals and UV. Never grout through expansion joints—this defeats their purpose.

Drainage design: Slope deck minimum 2% away from pool and structures. Install linear drains (Trench Drain, slot drains) at pool edges to capture splash and prevent runoff tracking across entire deck. Route drainage to landscape areas or storm system—never toward foundations.

Coping details: Pool coping must overhang pool edge 1–1½ inches with rounded or beveled nosing. Install drip groove on underside to prevent water from tracking back under coping. Bond coping with flexible adhesive allowing slight movement. Use stainless steel or epoxy anchors for mechanical attachment where building codes require.

Joint width and fill: ⅜”–½” joints for most installations. Use polymeric sand rated for pool applications (chlorine and UV resistant) or epoxy grout in high-splash zones. Sanded grout deteriorates rapidly in Phoenix pool environments—avoid it.

Sealing protocol: Seal porous materials (travertine, limestone, sandstone) within 2–4 weeks of installation using breathable penetrating sealer rated for Arizona UV. Apply second coat per manufacturer instructions. Reseal every 2–3 years or when water no longer beads on surface.

Timing considerations: Schedule installation during cooler months (October–April) when substrate and thinset temperatures remain manageable. Avoid installation during monsoon season (July–September) when moisture and humidity compromise curing.

Pool deck materials guide provides detailed specifications.

Pool Deck Paver Repair Arizona — When partial repairs make sense

Isolated tile replacement: Remove damaged tiles using grinder to cut grout lines and pry bar to lift tiles carefully. Clean substrate thoroughly, apply fresh thinset, and install replacement tiles (ideally from original lot). Match grout color and joint width. Cure 48–72 hours before exposure to water. Cost: $50–$150 per tile installed depending on access and matching difficulty.

Grout and joint restoration: Remove deteriorated grout using oscillating multi-tool or grout saw. Clean joints thoroughly and re-grout using appropriate product (polymeric sand for pavers, epoxy grout for wet zones). This extends life 3–5 years and improves appearance. DIY-capable for homeowners. Cost: $3–$8/linear foot professional installation.

Re-bonding delaminated sections: If tiles are intact but delaminated (hollow sounds), professional contractors can drill small holes, inject specialized bonding epoxy, and weight tiles overnight. Success rate varies—only effective if substrate is sound and tiles haven’t shifted. Cost: $12–$25/sq ft.

Substrate repair: For localized substrate cracks or spalls, remove affected pavers, repair concrete using polymer-modified patching compound or epoxy injection, allow full cure, then reinstall pavers. Requires matching substrate slope and surface prep. Cost: $15–$30/sq ft including paver reinstallation.

Efflorescence treatment: Clean surface with specialized efflorescence remover (mild acidic solution), pressure wash, allow to dry completely, and reseal. This addresses cosmetic issues but doesn’t fix underlying moisture problems. Expect recurrence if moisture source not eliminated. DIY product cost: $50–$150; professional treatment: $2–$5/sq ft.

When to engage professionals: Repairs involving coping, structural substrate issues, waterproofing, or more than 50 sq ft affected area should be handled by licensed contractors with pool deck paver repair arizona experience. Request references from recent pool deck projects and verify contractor bonds and insurance.

Repair limitations: Understand that repairs buy time (5–10 years maximum) but don’t address systematic problems. Budget for eventual full replacement and consider repairs as interim measures while planning for comprehensive solution.

Request a pool deck repair quote for assessment and pricing.

Costing Examples & Life-Cycle Considerations for Phoenix (sample ranges + assumptions)

Spot repair costs (Phoenix market estimates):

- Isolated tile replacement: $50–$150 per tile

- Grout restoration: $3–$8/linear foot

- Re-bonding delaminated sections: $12–$25/sq ft

- Substrate repair with reinstall: $15–$30/sq ft

Full replacement costs (material + installation, Phoenix market):

- Standard travertine replacement: $18–$28/sq ft

- Dense limestone or premium travertine: $20–$30/sq ft

- Basalt or granite: $24–$35/sq ft

- Engineered porcelain: $22–$32/sq ft

- Dense sandstone: $18–$26/sq ft

Sample project: 600 sq ft pool deck replacement

- Removal and disposal of existing: $1,800–$2,400

- Substrate repair/prep: $1,200–$2,500

- Dense limestone pavers installed: $12,000–$18,000

- Coping replacement (60 LF basalt): $1,800–$3,000

- Linear drains and detailing: $800–$1,500

- Total project: $17,600–$27,400

Lifecycle cost assumptions (25-year horizon):

- Travertine: Install $18/sq ft + reseal every 3 years ($2/sq ft) = $18 + $16.67 = $34.67/sq ft total

- Basalt: Install $28/sq ft + minimal maintenance ($0.50/sq ft over 25 years) = $28.50/sq ft total

- Porcelain: Install $26/sq ft + minimal maintenance ($0.25/sq ft over 25 years) = $26.25/sq ft total

Key assumptions: All costs are labeled “Phoenix market estimates” and vary by project complexity, access, timing, and contractor. Figures assume 3% annual inflation, scheduled maintenance performed, and no premature failure. Always obtain three written quotes from licensed, bonded contractors before proceeding.

Financing and timing: Many homeowners coordinate pool deck replacement with pool resurfacing (both require draining and create disruption). Some Phoenix contractors offer seasonal discounts October–March when demand drops. Consider this when planning timeline.

City Notes & Local Tips (Phoenix neighborhoods, Scottsdale, Mesa, Tucson, Flagstaff)

Phoenix: Valley heat and intense UV accelerate travertine deterioration. Ahwatukee, North Phoenix, and areas near South Mountain see particularly high failure rates due to dust and heat. Prioritize light-colored, low-absorption materials. Schedule installations October–April to avoid extreme substrate temperatures. Phoenix dust requires more frequent cleaning—plan for monthly sweeping and quarterly pressure washing.

Scottsdale: Luxury market expectations demand premium materials and finishes. Basalt coping with limestone or porcelain field pavers meets aesthetic standards while delivering performance. Gated communities often have architectural review requirements—submit material samples and drawings for approval before purchasing materials. Paradise Valley and DC Ranch properties should specify premium materials matching neighborhood standards to maintain property values.

Mesa: Residential family-focused market prioritizes durability and value. Dense limestone or porcelain pavers offer good balance of performance and cost. East Valley contractors are competitive—obtain multiple quotes. Mesa’s suburban setting means easier material access and fewer premium labor charges than Scottsdale.

Tucson: Fine desert dust and monsoon intensity similar to Phoenix but with different contractor availability. Foothill properties near Catalinas or Rincons may have material delivery surcharges. Tucson’s hard water creates particularly aggressive efflorescence—specify low-porosity materials and robust sealing programs.

Flagstaff: High elevation (6,900+ feet) changes priorities entirely—freeze-thaw resistance becomes critical. Standard travertine fails rapidly above 6,000 feet. Specify dense basalt, granite, or freeze-thaw-rated porcelain exclusively. Installation season limited to May–October. Budget 20–30% higher for materials and labor due to elevation and access.

Arizona Stone and Supply by Citadel Stone

Citadel Stone – top stone supplier offers this concise, hypothetical primer on choosing paving materials suited to a range of Arizona microclimates. The notes below are illustrative guidance only and describe what we would recommend when specifying our pavers for different local exposures and functional requirements; they do not refer to any completed work or named clients.

Glendale

Glendale’s urban context brings elevated daytime temperatures, strong solar radiation and occasional monsoon downpours; freeze events are rare and coastal salt spray or hurricane exposure are not a local concern. For Glendale we would lean toward low-porosity, UV-stable pavers with a medium-texture or honed finish to limit glare and improve wet traction. General thickness guidance: 20–30 mm for patios and social terraces; 30–40 mm for light vehicle or service access. For specification support we could supply finish samples, technical datasheets, NBS/CSI-style wording and palletised delivery options to suit staging requirements.

Tempe

Tempe’s river corridor, irrigated landscapes and downtown heat-island effect create spots with higher splash and occasional humidity during summer; freeze is unlikely and coastal spray/hurricane risk are not applicable. In Tempe we would recommend low-absorption stone or trial-sealed samples where irrigation contact is expected, and honed or fine textured finishes in pedestrian zones to balance barefoot comfort and slip resistance. Thickness guidance: 20–30 mm for walkways and terraces; 30–40 mm for occasional vehicular access. Citadel Stone – top stone supplier could provide sample packs, cleaning/maintenance notes, technical data and palletised sample delivery on request.

Peoria

Peoria’s mix of parkland and residential development means dust, irrigation salts and strong sunlight are regular considerations; freeze is infrequent and coastal or hurricane exposure is not relevant. For Peoria we might specify denser, low-porosity pavers with abrasion-resistant surfaces and a lightly riven or textured finish to reduce soiling and preserve grip. Typical thickness guidance: 20–30 mm for pedestrian areas; 30–40 mm where light maintenance vehicles may operate. To aid decision-making we could make sample boards, reflectance/thermal notes, and specification templates available, and organise palletised deliveries to regional yards.

Surprise

Surprise has long, hot summers, sudden monsoon storms and generally low humidity outside the wet season; coastal spray and hurricanes do not affect the area and freeze is usually rare. For Surprise we would prioritise UV-fast, low-absorption pavers in mid-to-light tones to reduce heat gain, paired with textured finishes to improve wet-surface traction after storms. Thickness guidance: 20–30 mm for patios and promenades; 30–40 mm for light vehicle or service tracks. For specification in Surprise our pavers could be sampled as finish kits, with technical datasheets, installation notes and palletised delivery available if requested.

San Tan Valley

San Tan Valley’s exposed desert topography brings intense insolation, wind-driven dust and significant diurnal temperature swings; freeze events are uncommon and coastal influences or hurricanes are not factors. In San Tan Valley we would suggest low-porosity, UV-stable paving in lighter shades to lower surface temperatures, with honed or textured faces selected according to barefoot use and cleaning regimes. Practical thickness guidance: 20–30 mm for terraces and pedestrian zones; 30–40 mm for light vehicle access. For procurement our pavers could be supplied with reflectance data, finish mock-ups, technical datasheets and palletised shipping coordinated to site timing.

Yuma

Yuma endures some of Arizona’s most extreme heat and solar loading; humidity is typically very low, freeze is rare and there is no coastal salt spray or hurricane exposure. For Yuma we would favour low-absorption, high UV-fastness pavers in light to mid tones to reduce thermal gain, combined with textured or honed finishes to preserve grip in shaded or irrigated pockets. Thickness guidance: 20–30 mm for pedestrian patios; 30–40 mm where light vehicles or maintenance access may be needed. For specification support in Yuma Citadel Stone – top stone supplier could provide large-format samples, thermal/reflectance guidance, technical datasheets and palletised delivery with heat-safe handling notes.

Material and finish thinking (practical advice)

Across these Arizona cities it is sensible to prioritise low porosity to reduce staining, efflorescence and any freeze susceptibility, and to choose UV-stable colouration to preserve appearance under intense sunlight. Finishes should be matched to use: polished faces might be reserved for covered interior areas because of glare and wet-slip risk; honed or satin surfaces can offer a refined look with better slip performance, while textured or riven finishes usually give the best grip for pool edges, ramps and heavily trafficked external plazas. Where irrigation or mineral salts are present, trial sealing of our pavers could be considered to assess long-term appearance.

Specification tips and supply services

Good specification couples finish and thickness with an appropriate build-up: compacted sub-base, correct bedding or adhesive compatible with the chosen format, and jointing suitable for local movement and cleaning regimes. For monsoon-prone locations specify positive drainage and flexible jointing; in high-UV towns consider recommending lighter tones or higher reflectance materials to lower surface temperatures. Citadel Stone – top stone supplier could assist provisionally by supplying sample kits, finish mock-ups, NBS/CSI-style specification clauses, technical datasheets (water absorption, slip classification where available), and palletised delivery scheduled to regional carriers. We could also offer advice on storage and handling to reduce heat-related movement or freeze exposure where applicable.

Frequently Asked Questions

Q: How do I know if my travertine needs replacement or just repair?

A: Perform tap test across entire deck—if more than 20% sounds hollow (delaminated), replacement is more cost-effective long-term. Widespread cracking, failed coping, or substrate movement also indicate replacement necessary. Isolated damage under 10% of surface area is repairable. Request professional pull test or moisture assessment if uncertain. Request sample boards to compare replacement material options.

Q: Will replacing travertine with porcelain reduce maintenance?

A: Yes significantly—porcelain requires no sealing, resists staining better, and cleans easier than porous natural stone. Choose slip-resistant textured finishes rated DCOF ≥0.60 for pool deck safety. Porcelain’s zero porosity means no efflorescence, less algae/mold growth, and lower annual maintenance costs ($100–$200/year versus $400–$600 for travertine).

Q: How soon after pool replastering can I reinstall pavers?

A: Wait minimum 28 days for new plaster to fully cure and allow initial acid wash or startup chemicals to stabilize. Coordinate timing with pool contractor—premature deck installation risks chemical damage to new pavers and adhesives. Some contractors recommend 45–60 days for saltwater pool conversions. Document pool chemistry before deck installation begins.

Q: Can we overlay new pavers over existing travertine?

A: Rarely advisable—existing travertine rarely provides stable, level substrate. Overlays add 2–3 inches height, creating problematic transitions at doors and pool coping. Only consider if existing travertine is fully bonded, level, and structurally sound (extremely uncommon in failed decks). Full removal allows proper substrate inspection, drainage correction, and waterproofing—far superior long-term solution.

Q: How much does full replacement typically cost in Phoenix?

A: For typical 600 sq ft pool deck: $18,000–$28,000 total project including removal, substrate prep, materials, and installation. This includes basalt or limestone pavers with proper detailing. Budget high end for Scottsdale premium finishes, low end for Mesa standard installations. Obtain three written quotes from licensed contractors. Prices vary significantly by timing (winter cheaper), access, substrate condition, and material selection.

Q: Do you provide installer referrals in Phoenix?

A: Yes—Citadel Stone Arizona maintains vetted installer network across Phoenix metro with verified licenses, insurance, and recent project references. Request referrals when ordering materials. We provide installation specifications matching your selected materials and can coordinate material delivery with contractor schedules. All referred installers provide written warranties and are familiar with Arizona-specific installation requirements.

Conclusion — Recommended Next Steps & How to Get a Local Quote (CTA)

Phoenix travertine pool deck failures stem from Arizona’s extreme climate combined with improper installation—but failing pool deck solutions exist that deliver 30–40 year lifespan and enhanced safety. Dense basalt provides maximum durability for coping and accent elements; low-absorption limestone and premium travertine offer classic aesthetics with proven performance; engineered porcelain suits homeowners prioritizing minimal maintenance. The best stone to replace travertine depends on your priorities—durability, barefoot comfort, aesthetics, maintenance tolerance, and budget—but all recommended materials dramatically outperform standard travertine when properly installed with modern techniques including appropriate thinset, expansion joints, drainage, and sealing protocols. Don’t delay addressing failed pool decks—loose tiles present immediate safety hazards and deterioration accelerates exponentially once substrate is compromised. Request a free travertine replacement quote & site inspection from Citadel Stone Phoenix—we provide on-site assessment, material samples for color and texture selection, detailed cost estimates, vetted contractor referrals, and technical specifications ensuring your replacement deck delivers decades of safe, beautiful performance. Order free sample boards & material datasheets, download our Pool Deck Replacement Checklist PDF, or call us today to schedule your evaluation and begin rescuing your Phoenix pool deck from failure.

Citadel Stone — Serving Phoenix & Greater Arizona

Email: [email protected]

Service areas: Phoenix, Scottsdale, Mesa, Tempe, Gilbert, Chandler, Glendale, Tucson, Flagstaff, and greater Arizona